Power converter

A power converter and circuit technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, instruments, etc., can solve the problems of limited power, complex circuit, single-stage isolation converter is difficult to meet the demand, etc. Achieve high power density and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

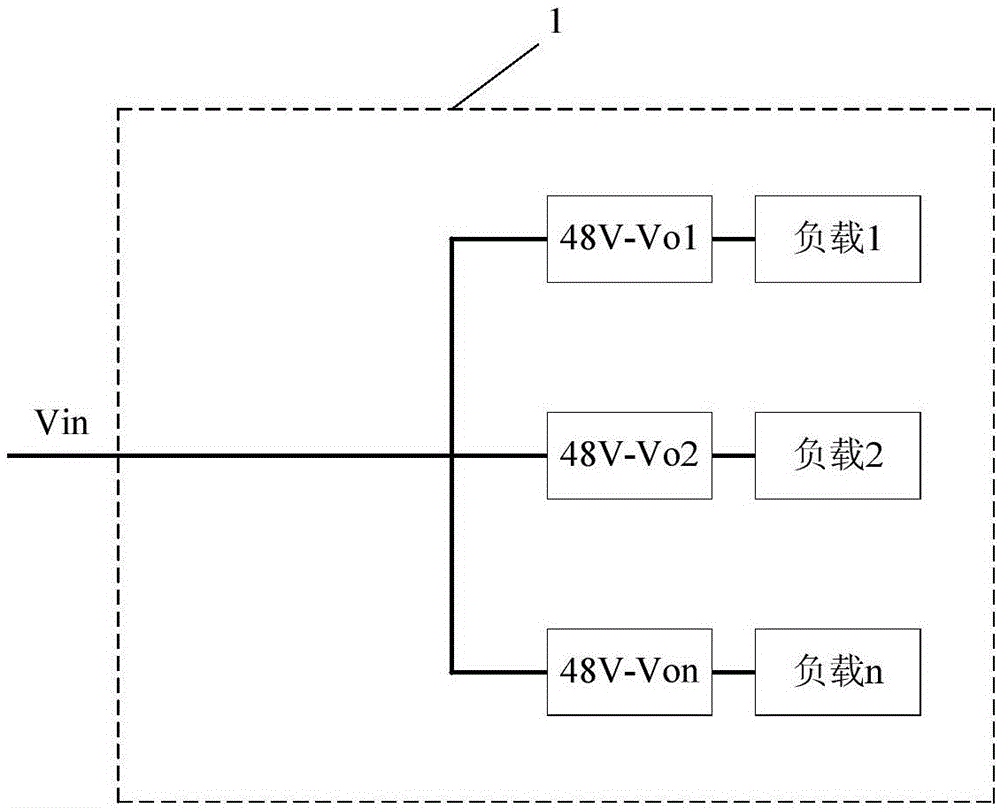

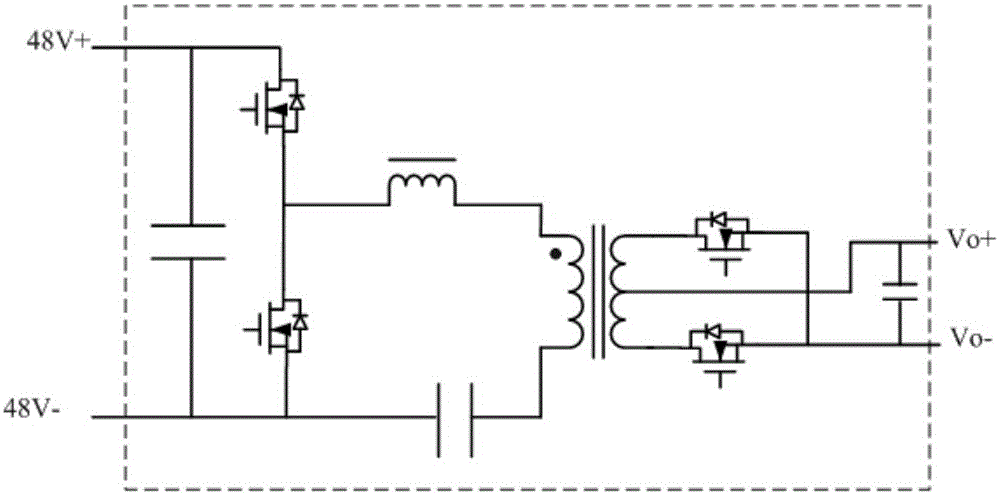

[0054] This embodiment provides a power converter. The power converter includes two stages of circuits, namely a front-stage circuit and a rear-stage circuit. The front-stage circuit is used to receive an input voltage and convert the received input voltage into a bus voltage Output the bus voltage; the latter circuit can be multiple, connected in parallel to the output end of the previous circuit, used to receive the bus voltage output by the previous circuit, and convert the bus voltage into an output voltage respectively, and supply the connection It is used for the load at the output end of the post-stage circuit.

[0055] Next, the power converter of this embodiment will be described with reference to specific examples.

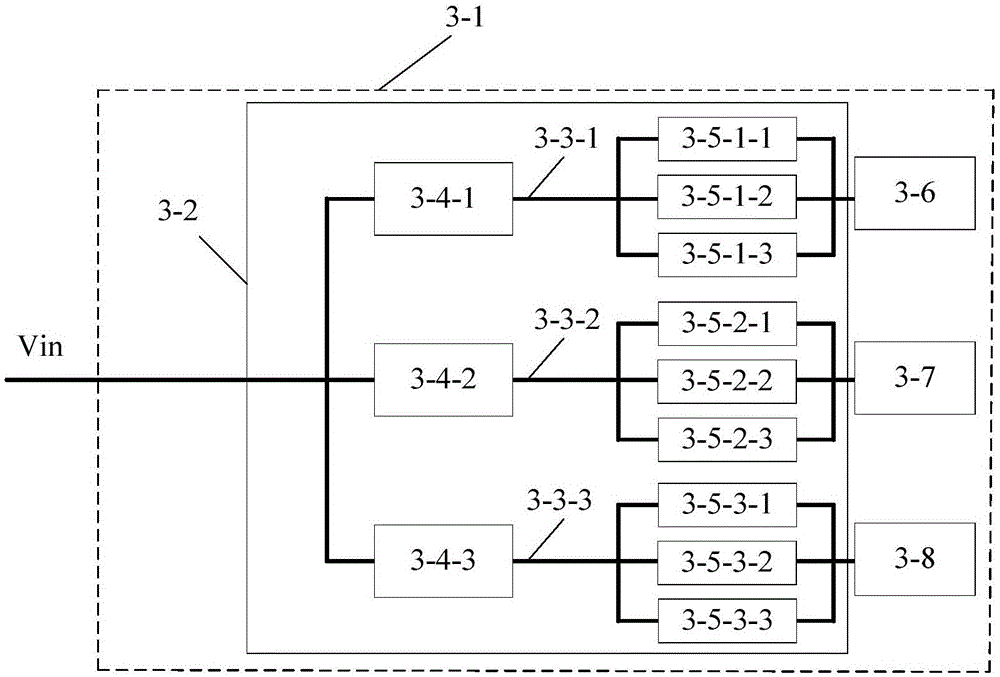

[0056] Figure 3A A schematic structural diagram of the power converter provided by this embodiment is shown, as Figure 3A As shown, the power converter 3-2 includes multiple pre-stage circuits and multiple post-stage circuits. The input ends of the ...

Embodiment 2

[0072] Figure 7 shows the package structure diagram of the power converter, in Figure 7 The front stage circuit (taking the LLC circuit as an example) 7-2 and the rear stage circuit (taking the BUCK circuit as an example) 7-3 are packaged in independent modules respectively, and are carried on the data processing main board 7-1. The motherboard 7-1 also carries a CPU 7-6 and a radiator 7-7, wherein the radiator 7-7 is used to dissipate heat for the CPU 7-6, and the power converter is used to provide power to the CPU 7-6. The front-stage circuit 7-2 includes an output capacitor 7-4, and the rear-stage circuit 7-3 includes an input capacitor 7-5. The front and back stage circuits are respectively located in their own packaging modules, forming two independent components. In practical applications, the distance between the output capacitor 7-4 of the previous stage circuit and the input capacitor 7-5 of the subsequent stage circuit is relatively long, and there is a relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com