Double planet carrier type circular gear and non-circular gear planetary gear set pot seedling transplanting mechanism

A non-circular gear, planetary gear train technology, applied in the field of agricultural machinery, can solve the problems of complex mechanism, unfavorable seedlings, stem damage at the bottom of seedlings, etc. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

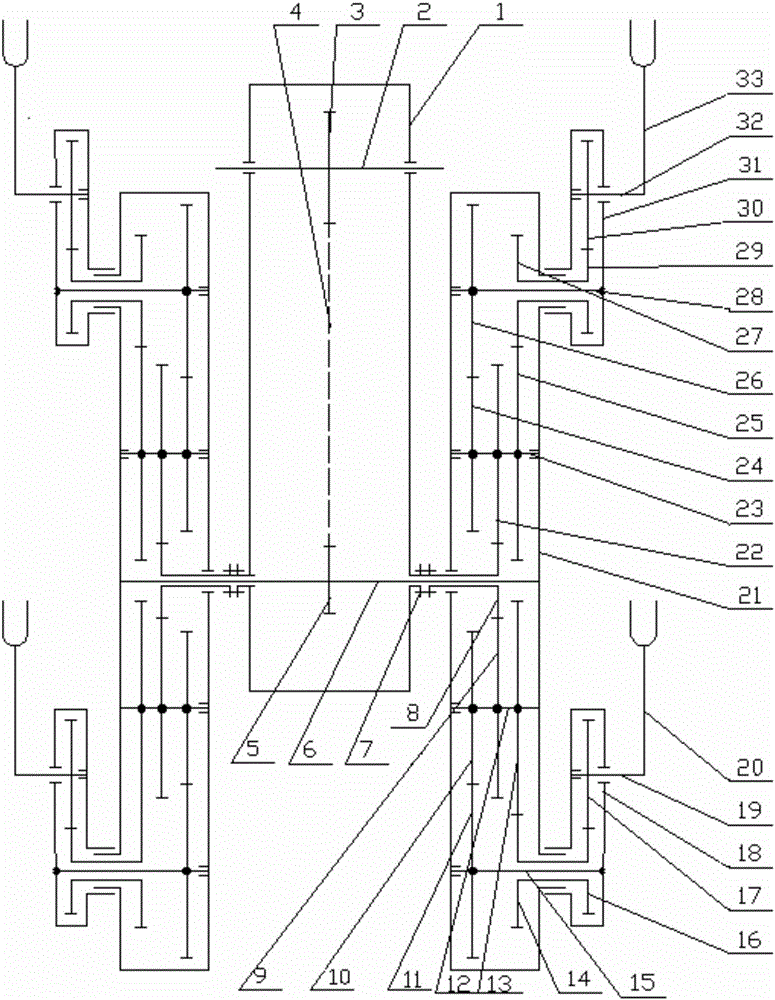

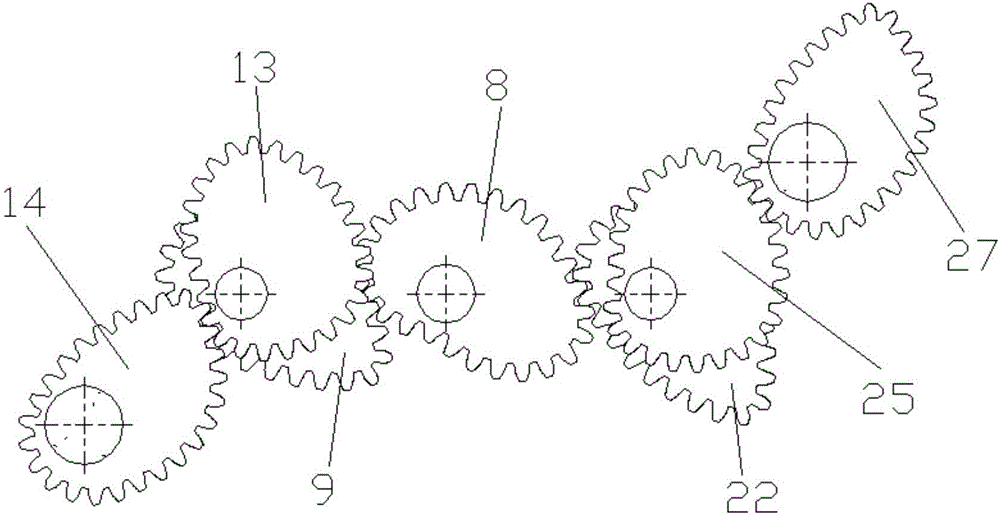

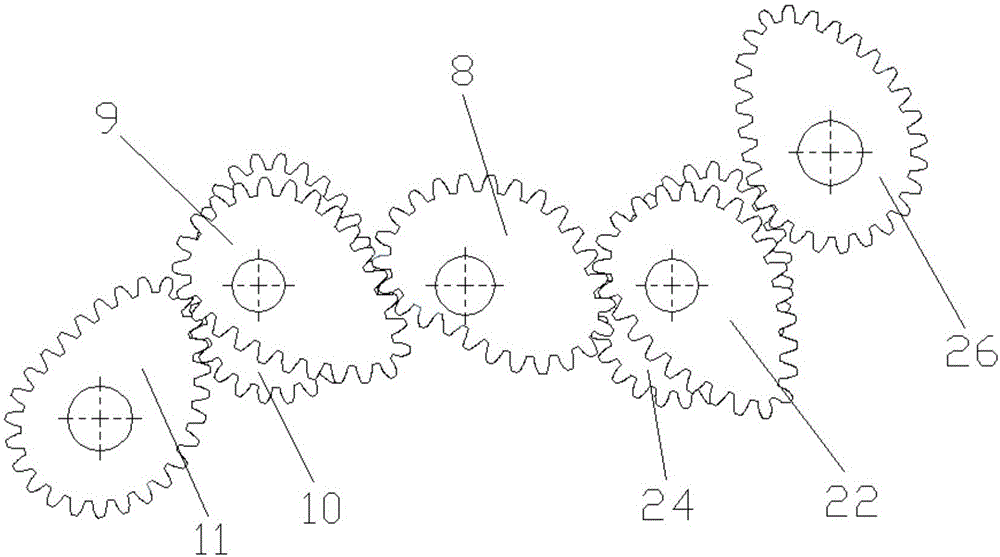

[0024] Such as figure 1 , 2 As shown in and 3, the seedling transplanting mechanism of the double planet carrier circular gear-non-circular gear planetary gear system includes a power drive box 1, a drive sprocket shaft 2, a drive sprocket 3, a chain 4, a center sprocket 5, and a center shaft 6. The main planetary gear train, the upper auxiliary planetary gear train, the lower auxiliary planetary gear train, the upper planting arm 33 and the lower planting arm 20; the driving sprocket shaft 2 and the central shaft 6 are supported at both ends of the power drive box 1 through bearings; The driving sprocket 3 on the driving sprocket shaft 2 is connected with the central sprocket 5 fixedly on the central shaft 6 by the chain 4; the two ends of the central shaft 6 are symmetrically provided with two main planetary gear trains, the main planetary gear train The two ends ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com