Special insect killing and sterilizing equipment for archives

A technology for sterilization equipment and archives, which is applied in sanitary equipment for toilets, devices for catching or killing insects, and applications. Not easy to save, avoid the effect of operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

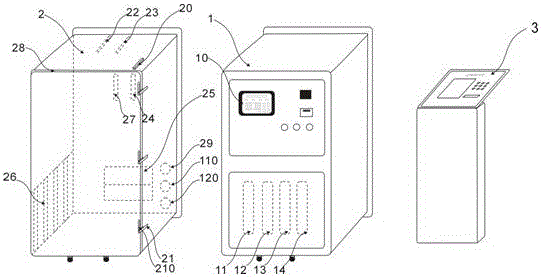

[0060] Such as figure 1 As shown, a kind of special-purpose insecticidal and sterilizing equipment for archives described in Embodiment 1 of the present invention includes a control chamber 1, a vacuum chamber 2, and a vertical touch controller 3;

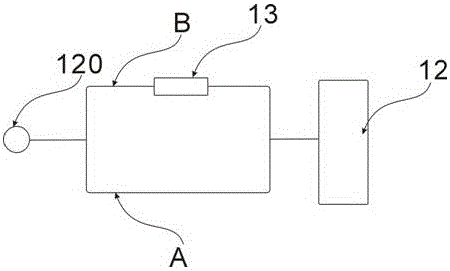

[0061] The control room 1 includes an operating platform 10, a vacuum pump 11, a nitrogen generator 12, a humidifier 13, and an air compressor 14; wherein the operating platform 10 is located above the control room 1, and its main program uses a touch control program. Through the operating platform 10 Real-time control and monitoring of equipment; vacuum pump 11, nitrogen generator 12, humidifier 13, and air compressor 14 are all located under the operating platform 10; the vacuum pump 11 is connected to the vacuum pump tube on the rear side wall of the vacuum chamber 2 through the pipeline It is connected to the delivery port 110 of the vacuum chamber for pumping out the gas in the vacuum chamber 2; wherein the nitrogen generator ...

Embodiment 2

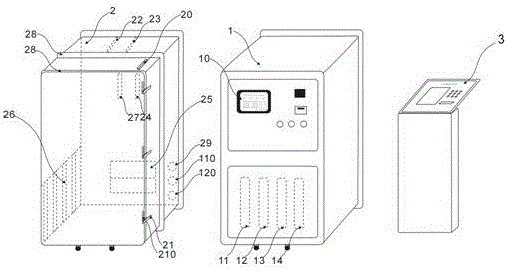

[0080] As shown in Figure 2, the difference between Embodiment 2 and Embodiment 1 is that: the vacuum chamber 2 can be set as a split structure, the vacuum chamber 2 is separated from the front and back, which is convenient for handling, and the interface is provided with a sealing ring 28 to isolate the equipment. Indoor and outdoor air contacts during operation, and other composition and connection methods are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com