Production line of foldable ballet shoes and production process of foldable ballet shoes

A production process and production line technology, which is applied to the egg roll shoe production line and the production process field thereof, can solve problems such as affecting the health of staff, affecting the heating effect, affecting the viscosity of glue, etc., and achieves good shaping effect, high production efficiency, and improved product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

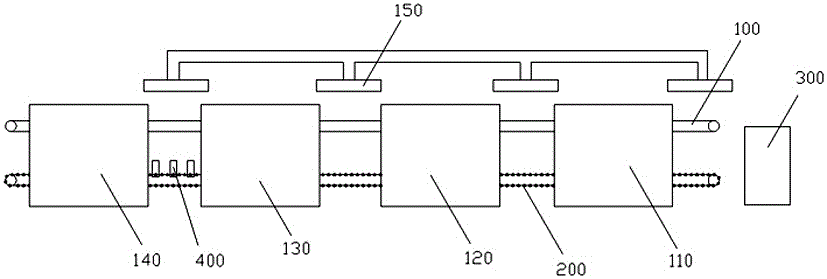

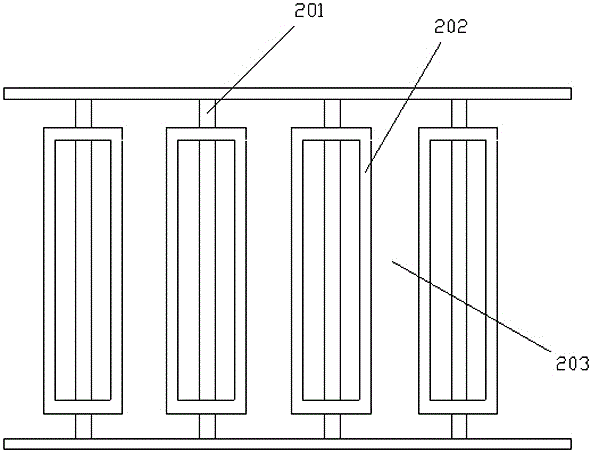

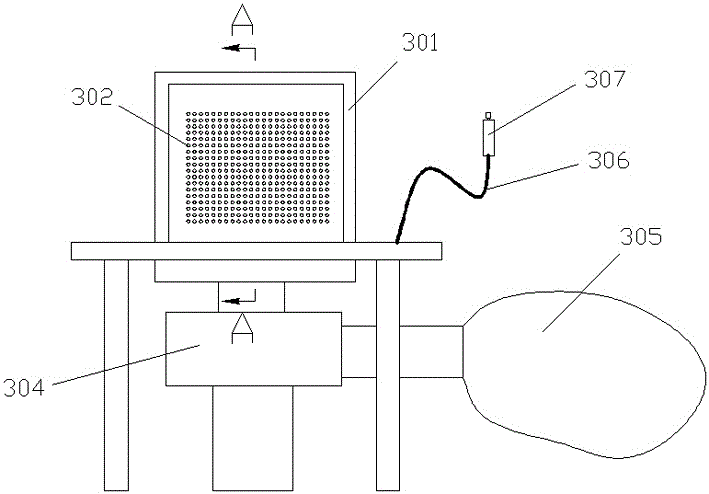

[0025] Such as Figure 1~2 As shown, an egg roll shoe production line includes a first conveying device 100 located on the upper floor and a second conveying device 200 located on the lower floor, both of the first conveying device 100 and the second conveying device 200 pass through the first oven 110 in sequence , the second oven 120, the third oven 130 and the freezing chamber 140; the grinding device 300 that is positioned at the side of the feeding end of the second conveying device 200 to polish the soles; the second conveying apparatus between the third oven and the freezing chamber A plurality of auxiliary positioning devices 400 for bonding, assembling and positioning the sole and the upper are arranged on the side of the device.

[0026] In this embodiment, the first oven 110, the second oven 120 and the third oven 130 are all heated by infrared rays, and the three ovens and the freezer are all provided with an upper temperature control chamber corresponding to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com