Special liquid taking device for flammable liquid

A technology for flammable liquids and liquid needles, which can be applied to measuring tubes/pipettes, laboratory containers, chemical instruments and methods, etc. Solve the effect of slow failure of reagents, high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

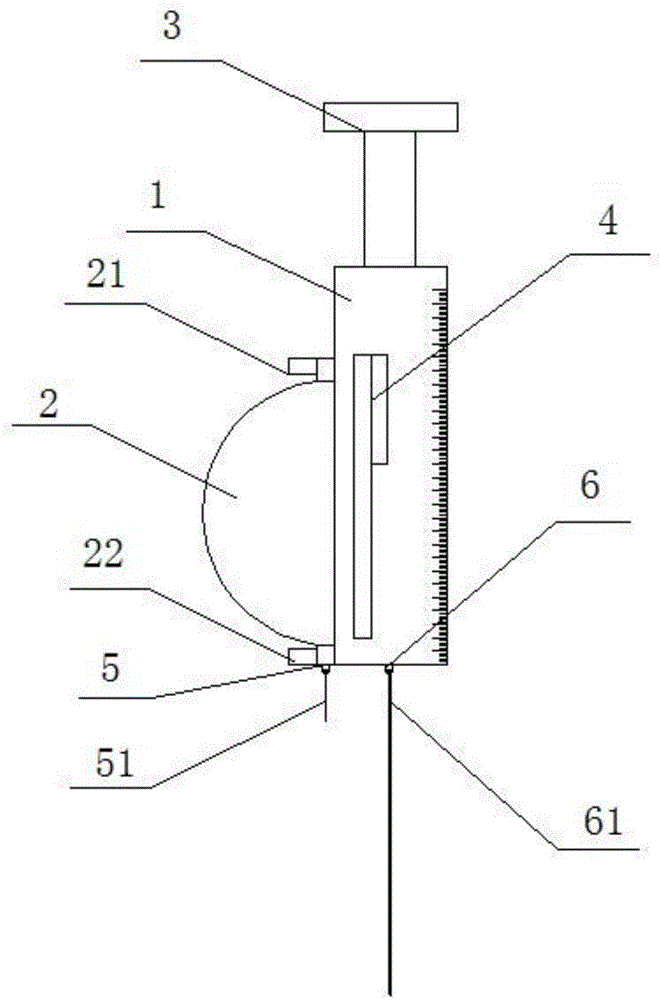

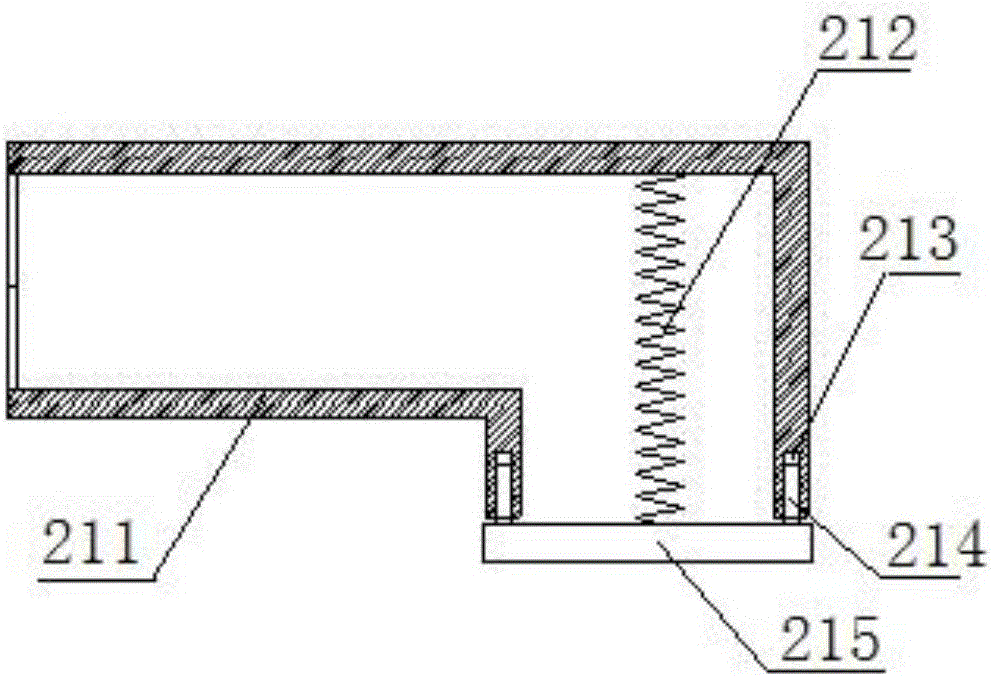

[0026] Such as Figure 1-Figure 2 As shown, a special liquid-taking device for flammable liquids includes a liquid-taking cylinder 1, a piston 3 is set inside the liquid-taking cylinder 1, a liquid-taking port 6 is provided at the bottom of the liquid-taking cylinder 1, and the liquid-taking port 6 A liquid-taking needle 61 is provided at the position, and a protective air bag 2 is provided on the side of the liquid-taking cylinder 1. The upper and lower ends of the protective air bag 2 are respectively provided with an air inlet 21 and a ventilation port 22. The air inlet 21 is An air intake pipe 211 is provided, and the air intake pipe 211 extends into the protective airbag 2. An air intake valve is provided on the air intake pipe 211. The air intake valve includes a spring member one 212 and an air pressure cover one 215. The air pressure cover one 215 is located at Protect the outlet of the air intake pipe 211 in the air bag 2, and the spring member one 212 connects the ai...

Embodiment 2

[0030] Further optimization is carried out on the basis of a special liquid-taking device for flammable liquids described in Embodiment 1. The junction of the air intake pipe 211 and the air pressure cap 215 is provided with a guide groove 1 213 along the axial direction of the intake pipe 211, The corresponding position of the air pressure cover one 215 is provided with a guide post one 214, and the guide post one 214 is sleeved inside the guide groove one 213, and the connection between the air intake pipe 211 and the air pressure cover one 215 is provided with a sealing ring; The embodiment can effectively prevent the displacement of the air pressure cover 1 215 and ensure the airtightness of the device.

Embodiment 3

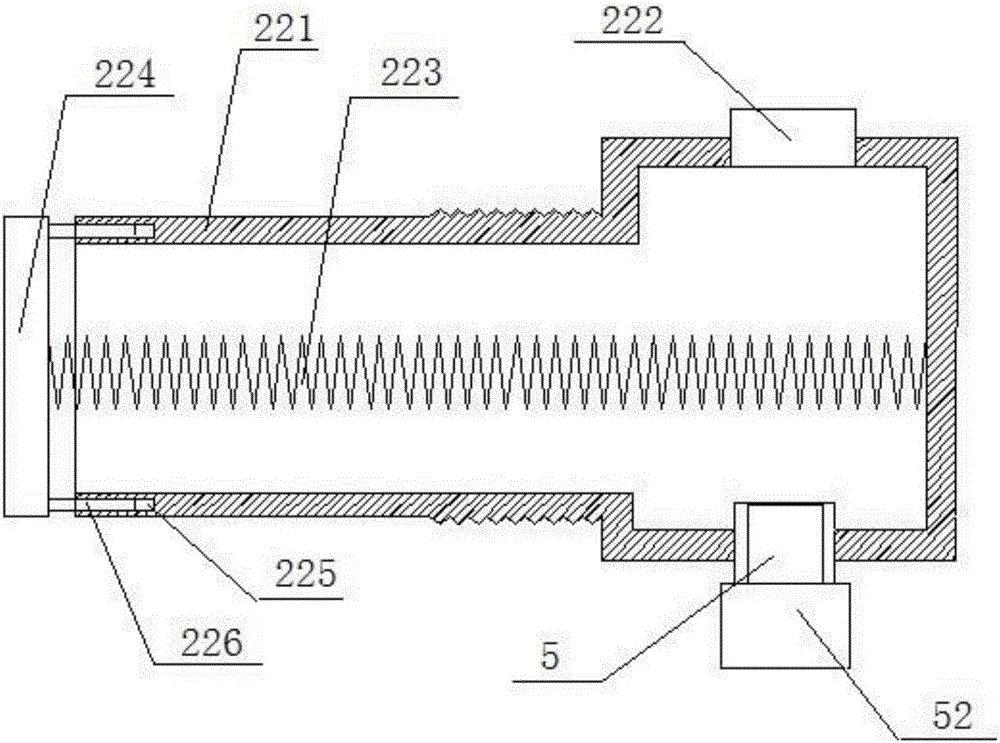

[0032] Such as image 3 As shown, further optimization is carried out on the basis of a special liquid-taking device for flammable liquids described in Embodiment 1, a spring member 2 223 is provided inside the vent tube 221, and an air pressure tube 223 is provided at the outer end of the vent tube 221. Cover two 224, the air exchange tube 221 and the air pressure cover two 224 are connected through the spring part two 223. In this embodiment, when the gas inside the protective airbag 2 is drawn out, the inside of the protective airbag 2 is negative pressure, and the spring part 223 Under the pulling force of the second and the effect of the external atmospheric pressure, the air pressure cover 224 blocks the ventilation pipe 221, preventing external gas from entering the inside of the protective airbag 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com