Production process for silicone pad

A production process and technology of silicone pads, applied in the field of production technology of silicone pads, can solve the problems of whitening, large power consumption and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

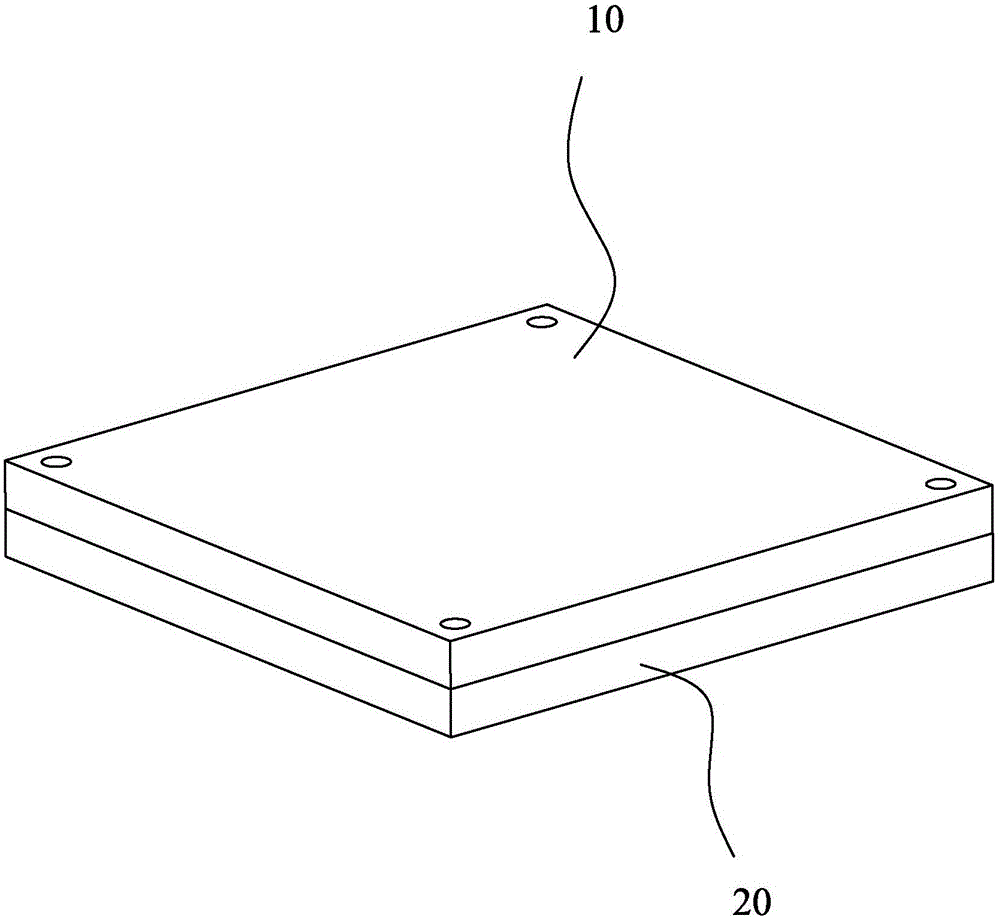

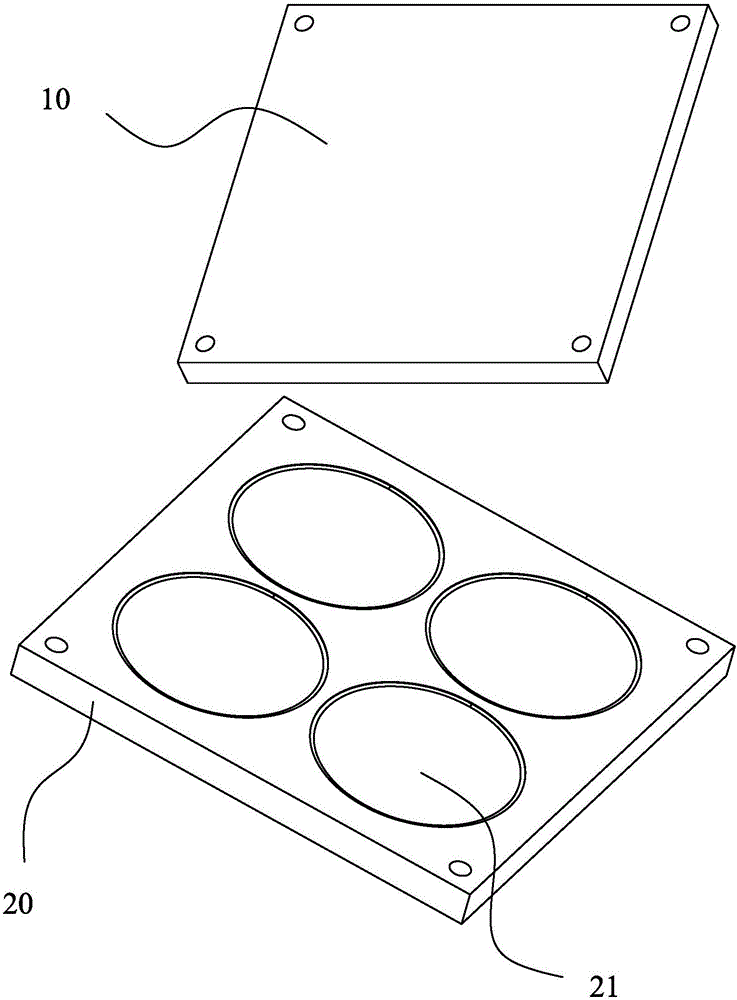

[0031] A kind of production technology of silica gel pad, it is characterized in that: comprise the following steps:

[0032] Step 1, the first heat press: hot press the first silicone layer on the back of the fabric to obtain a semi-finished silicone pad; during hot pressing, solid glue can be injected on the back of the fabric and then hot pressed or liquid silicone can be injected through the AB mixer On the back of the fabric and then hot press, the temperature is best controlled at 120°C during hot pressing;

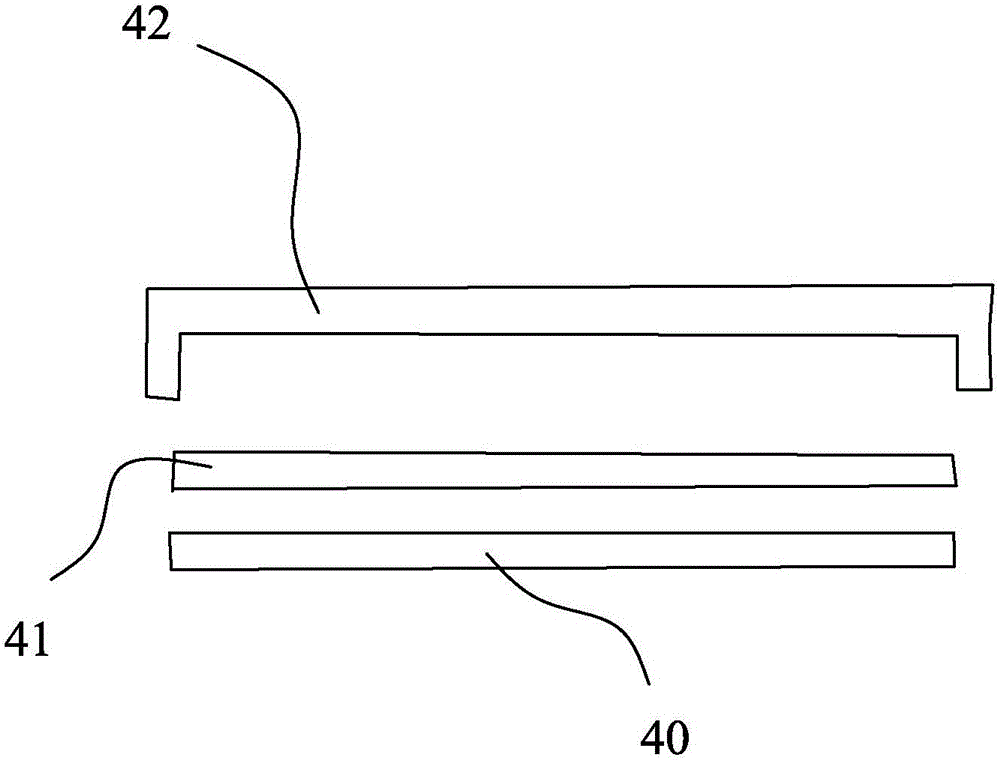

[0033] Step 2. Punching edge material: Punch out the desired shape of the semi-finished silicone pad; when punching, the silicone edge and the cloth edge of the semi-finished silicone pad are punched at the same time;

[0034] Step 3, the second hot pressing: heat-press the second silica gel layer through the mold on the front of the die-cut semi-finished silica gel pad, and make the second silica gel layer cover the side of the semi-finished silica gel pad; it is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com