High-elastic knitted fabric for underpants waistband and manufacturing method of high-elastic knitted fabric

A technology for knitted fabrics and waistbands, which is applied to high elastic knitted fabrics and their production, knitted fabrics and their production fields, can solve the problems of wearing discomfort, high oil content, and high spandex content, and achieves improvement of horizontal stripes. The effect of production efficiency and uniform yarn feeding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

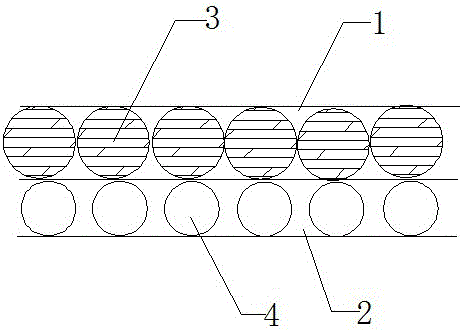

[0020] Such as figure 1 As shown, the high-elastic knitted fabric for underwear waist of the present invention includes a surface layer 1 and a bottom layer 2; the surface layer 1 is uniformly woven from a plurality of nylon 70D / 68F3; the bottom layer 2 is uniformly woven from a plurality of spandex 105D4 Woven; the content of the surface layer 1 accounts for 60% to 67% of the total weight; the content of the bottom layer 2 accounts for 33% to 40% of the total weight.

[0021] The preparation method of the high-elastic knitted fabric used for underwear waistband of the present invention, described comprises the following steps:

[0022] The first step is to choose materials. Nylon 70D / 68F and spandex 105D are selected. In order to keep the fabric easy to stretch and recover, and have long-lasting anti-fatigue and non-deformation functions, spandex uses spandex 105D, and the content in the fabric is 33~40%. ;Although the cost of spandex 70D is low, its holding power is insuffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com