A prefabricated pipeline maintenance well with anti-corrosion function

An overhaul well and prefabricated technology, applied in anti-corrosion coatings, artificial islands, coatings, etc., can solve the problems of long-term immersion in groundwater, corrosion damage of equipment and facilities, and inconvenient equipment control, so as to shorten the construction period and improve the construction. Efficiency and the effect of reducing the difficulty of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

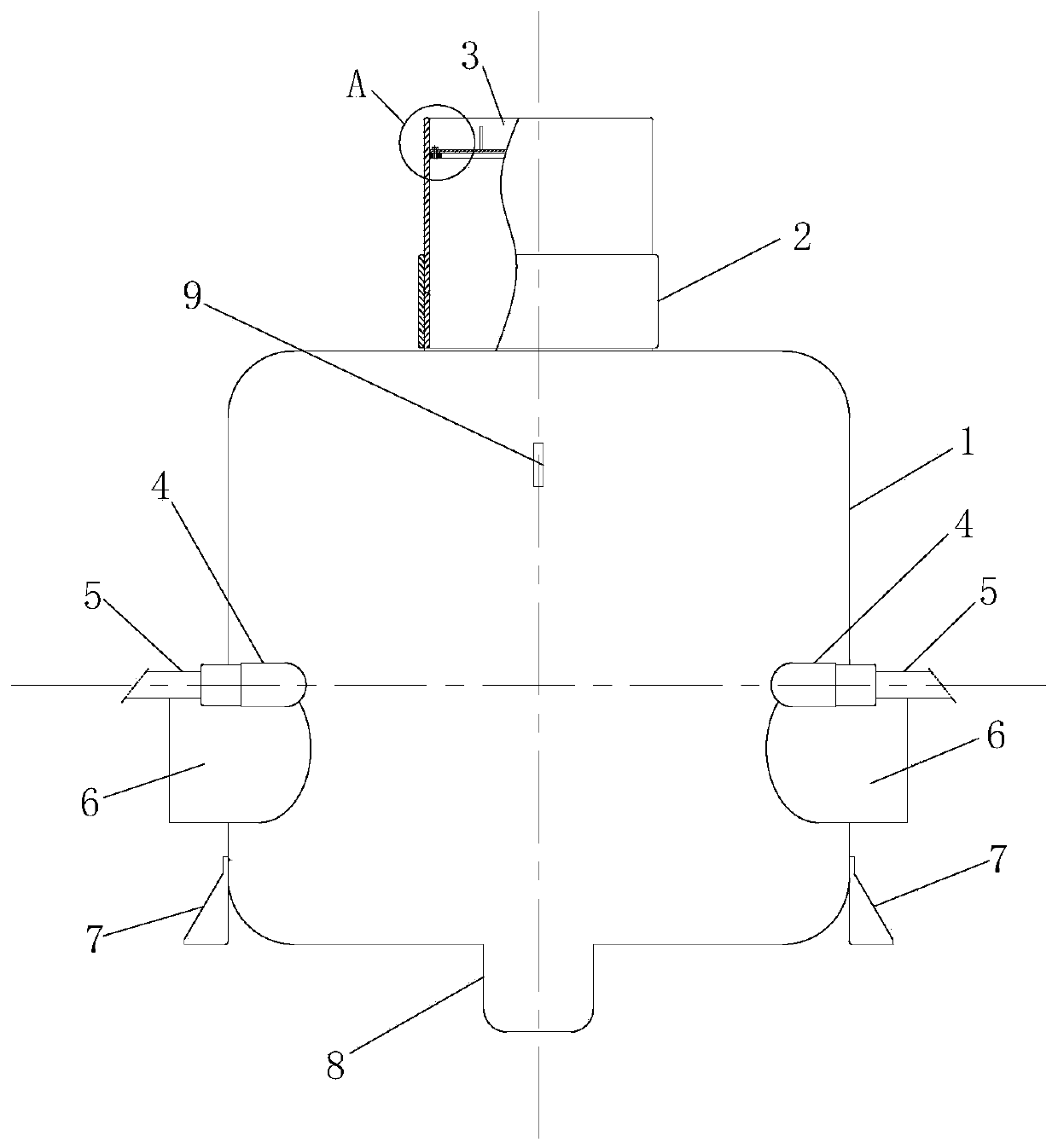

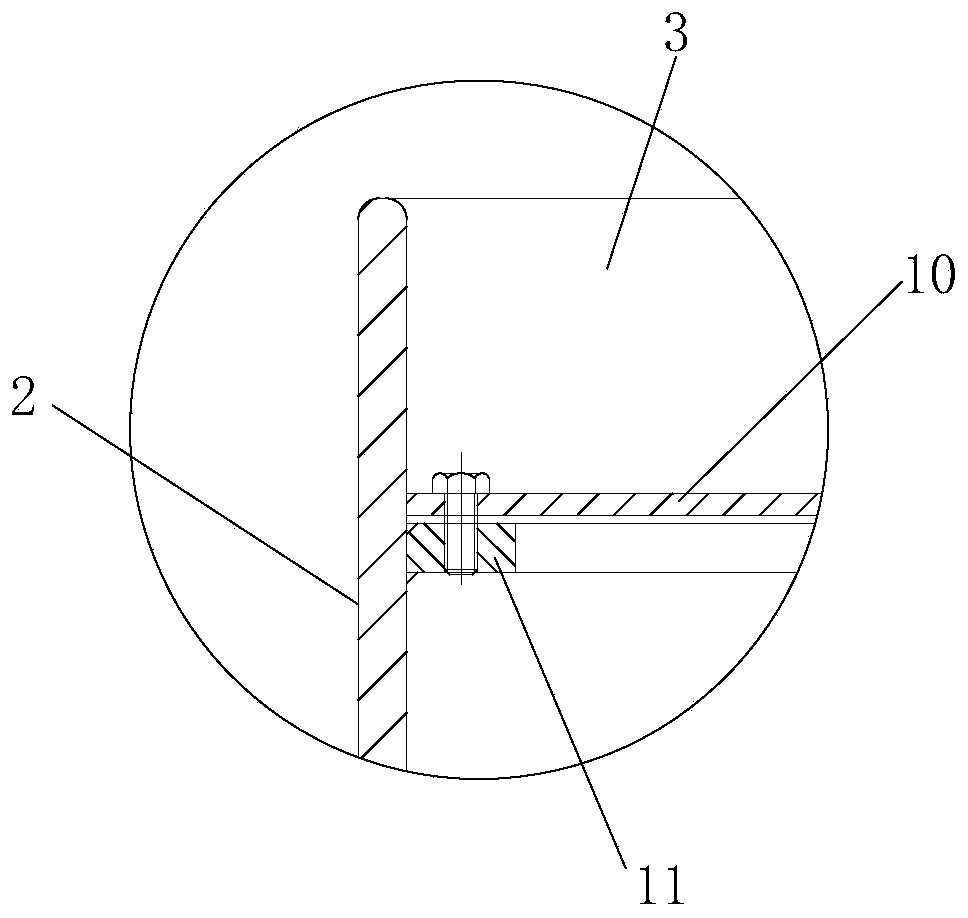

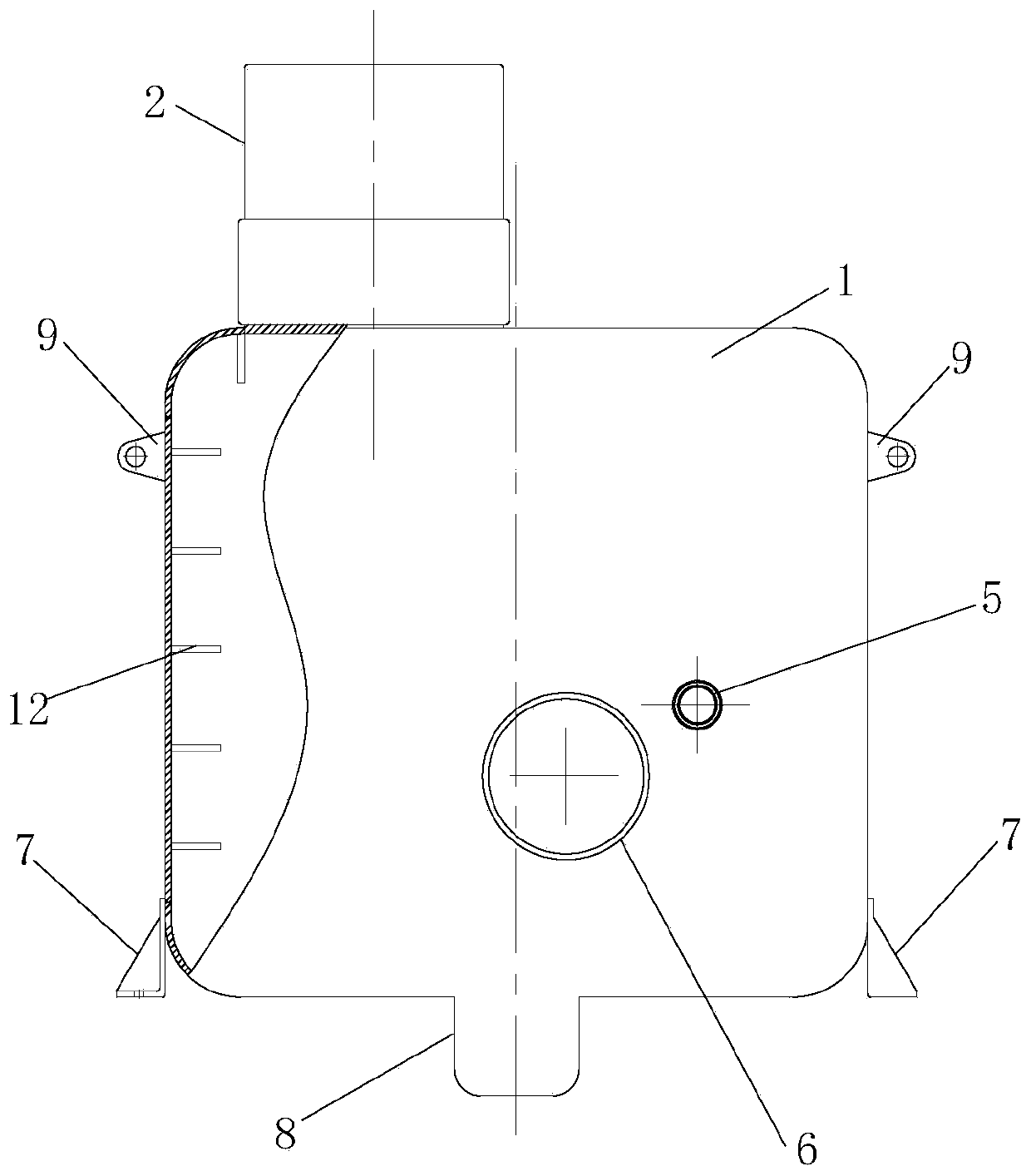

[0037] Such as figure 1 , figure 2 with image 3 The shown prefabricated pipeline maintenance well with anti-corrosion function includes a steel maintenance well body 1 with a hollow structure. The upper end of the maintenance well body 1 is provided with a well neck 2. There is a well cover 10 for closing the wellhead 3 at the upper end of the well neck 2. The side wall of the maintenance well body 1 is provided with two reserved pipes 6, and one end of the two reserved pipes 6 is connected to the maintenance shaft body. 1 is connected, the side wall of the maintenance well body 1 is provided with a casing 4, and the casing 4 is provided with a threading pipe 5 for leading out the lines of each equipment in the maintenance well body 1; the maintenance well body 1 The outer surface of the outer surface, the outer surface of the well neck 2, the outer surface of the well cover 10, the outer surface of the reserved pipe 6, the outer surface of the casing 4 and the outer surfa...

Embodiment 2

[0060] The difference between this example and Example 1 is that the low-temperature-resistant solvent-free thick-film epoxy anticorrosion coating is prepared by uniformly mixing component A and component B in a weight ratio of 4:1.

[0061] In this embodiment, the A component contains the following components by weight: 100kg composite toughened epoxy resin, 20kg anti-dripping gel, 50kg precipitated barium sulfate, 10kg iron oxide red, 40kg sericite, 30kg talcum powder, Germany Bi Ke BYK-A530 defoamer 4kg, German Bi Ke BYK-3550 leveling agent 4kg; Described composite toughened epoxy resin is the polypropylene glycol ether polyurethane prepolymer ( Bayer XP2540) is mixed according to the weight ratio of 100:10; The anti-dripping gel is made according to the weight ratio of 8:5:30:100 by silane coupling agent KH550, fumed silica, nano-titanium dioxide and composite epoxy resin Prepared by mixing; the composite epoxy resin is made by uniformly mixing bisphenol A epoxy resin E51 ...

Embodiment 3

[0073] The difference between this example and Example 1 is that the low-temperature-resistant solvent-free thick-film epoxy anticorrosion coating of this example is prepared by uniformly mixing components A and B in a weight ratio of 3:1.

[0074]The A component contains the following components by weight: 100kg of composite toughened epoxy resin, 50kg of anti-dripping gel, 50kg of precipitated barium sulfate, 50kg of talcum powder, and 5kg of German BYK-A530 defoamer; Tough epoxy resin is made by mixing composite epoxy resin and toughening agent polymerized phenol-terminated polypropylene glycol ether polyurethane prepolymer (Bayer XP2540) in a weight ratio of 100:50; the anti-dripping gel is made of silane coupling agent KH560, fumed silica, nano-titanium dioxide and composite epoxy resin are mixed according to the weight ratio of 10:10:5:100; the composite epoxy resin is made of bisphenol A type epoxy resin E44, bisphenol F type Epoxy resin 170 and polypropylene glycol dig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com