Tail-end pose detection system and method for flexible parallel platform with photoelectronic packaging

A detection system and optoelectronic technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems affecting the effect of platform posture detection and adjustment, and achieve the effect of saving space, cost, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

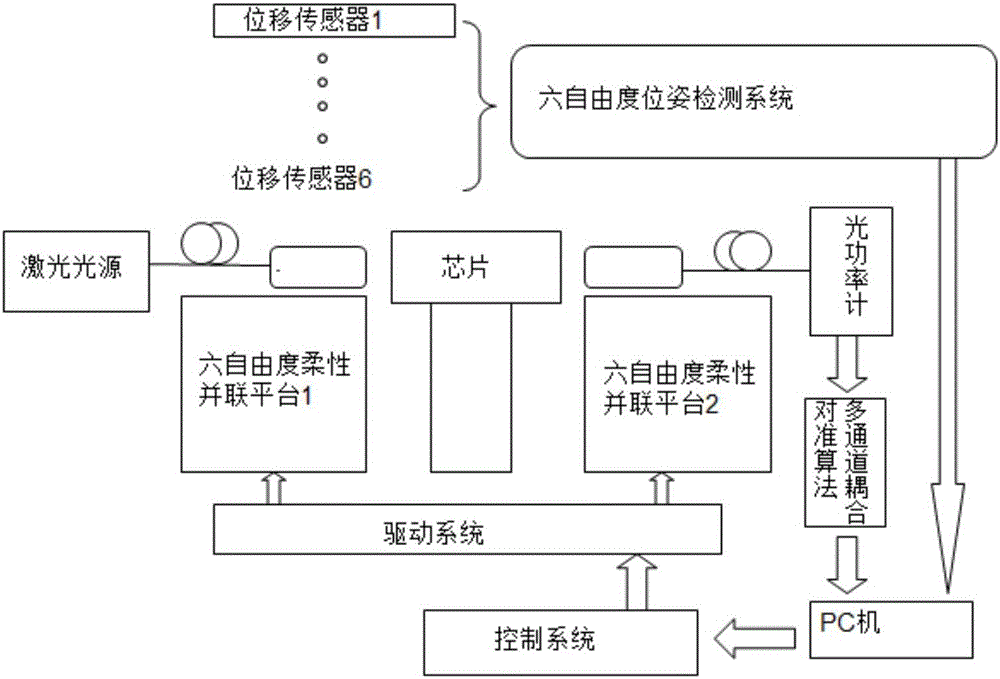

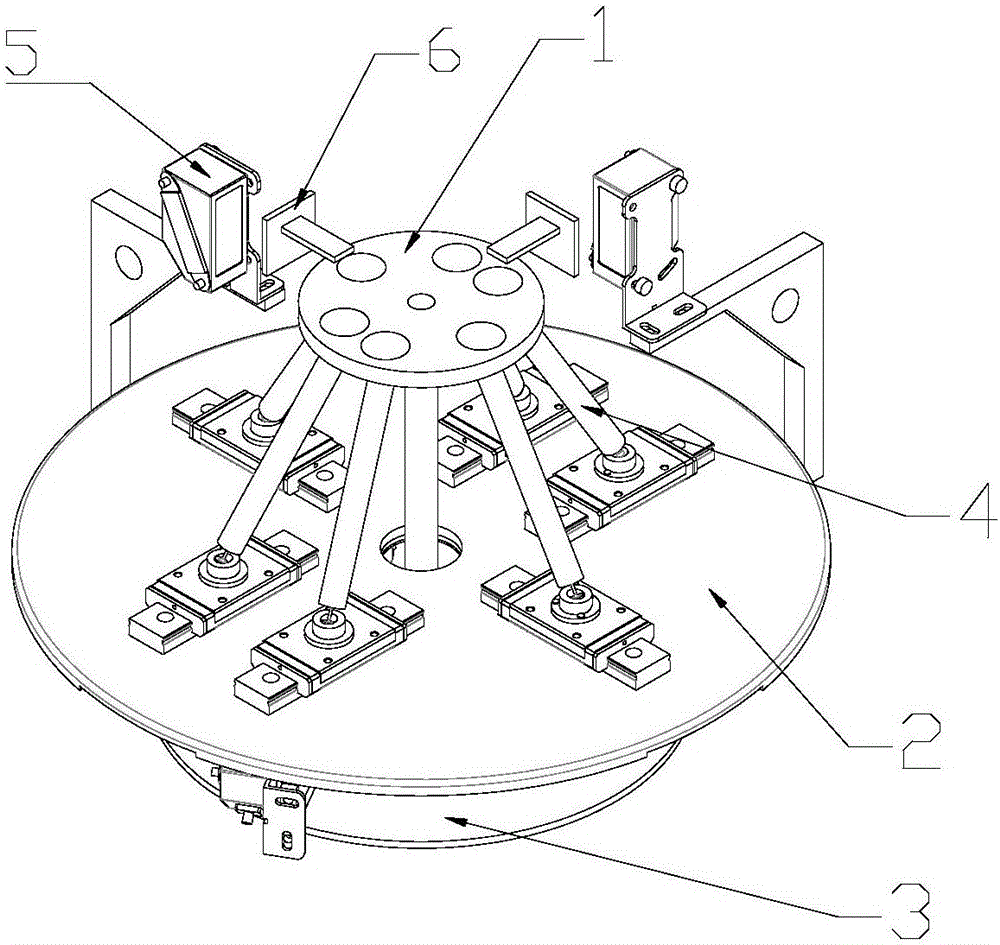

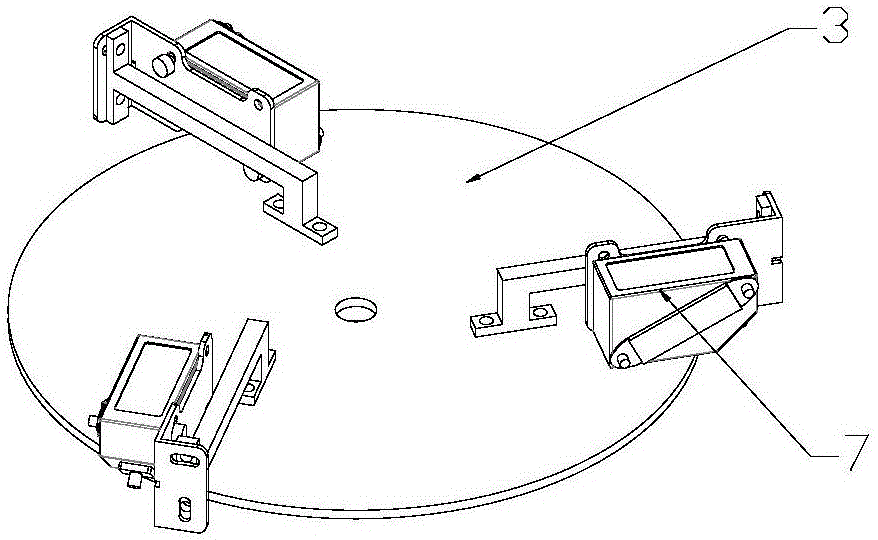

[0029] The pose detection, adjustment and alignment process of the flexible parallel platform is as follows: figure 1 shown. The flexible parallel platform is driven by six motors. By controlling the six motors, the terminal pose detection and adjustment of the flexible parallel platform is realized. In the past, the control of the six-degree-of-freedom flexible parallel platform was indirectly obtained by calculating the displacement of the grating ruler. For the terminal pose of the parallel platform, the macro-micro detection device designed now can directly detect the terminal pose. The detection device appears as a feedback during control. The macro-micro combined d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com