Method for preparing cholesteric liquid crystal functional film by heating-ultraviolet light stepwise polymerization

A cholesteric liquid crystal, step-by-step polymerization technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems affecting product economic benefits, reducing product performance and quality, and insufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

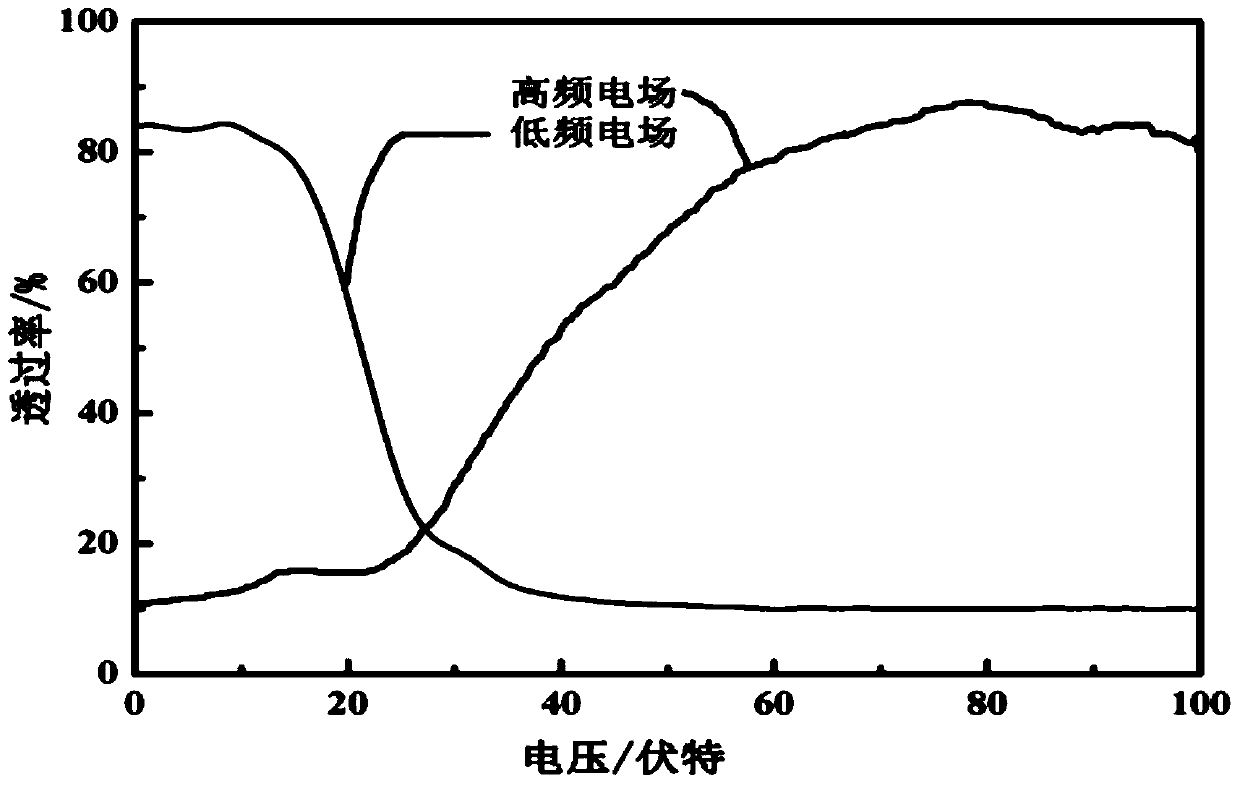

Embodiment 1

[0061] The liquid crystalline ultraviolet photopolymerization monomer (compound 1) that is 3wt% by weight and the cholesteric phase liquid crystal mixture that is 97wt% by weight (the cholesteric phase liquid crystal mixture that selects in the present invention is the chiral phase that contains 14% by weight Additive S811 is mixed with nematic phase liquid crystal mixture, the composition of nematic phase liquid crystal mixture is shown in Table 1) and photoinitiator Irgacure651 are uniformly mixed, as the ultraviolet polymerizable monomer liquid crystal composite system, the addition amount of photoinitiator is liquid crystal ultraviolet 5% of the total mass of the photopolymerizable monomer and the cholesteric liquid crystal mixture; 50% by weight of polythiol curing agent Capcure 3-800 and 50% by weight of E51 containing conjugated epoxy groups Epoxy resin / glycidyl ester ERL-4221 epoxy resin is mixed evenly as a thermal polymerization composite system; the thermal polymeriz...

Embodiment 2

[0067] The liquid crystalline ultraviolet photopolymerization monomer (compound 2) that is 1wt% by weight and the cholesteric liquid crystal mixture that is 99wt% by weight (the cholesteric liquid crystal mixture that selects in the present invention is the chiral liquid crystal that contains 14% by weight Additive R811 is mixed with nematic phase liquid crystal mixture, the composition of nematic phase liquid crystal mixture is shown in Table 1) and photoinitiator Irgacure651 are evenly mixed, as the ultraviolet polymerizable monomer liquid crystal composite system, the addition amount of photoinitiator is liquid crystalline ultraviolet 0.01% of the total mass of photopolymerizable monomer and cholesteric liquid crystal mixture; 20% by weight of polythiol type curing agent Capcure 3-800 and 80% by weight of E51 containing conjugated epoxy groups Epoxy resin / glycidyl ester ERL-4221 epoxy resin is mixed evenly as a thermal polymerization composite system; the thermal polymerizat...

Embodiment 3

[0070] The liquid crystalline ultraviolet photopolymerizable monomer (compound 3) that is 6wt% by weight and the cholesteric phase liquid crystal mixture that is 94wt% by weight (the cholesteric phase liquid crystal mixture that selects in the present invention is the chiral liquid crystal that contains 14% by weight Additive R1011 is mixed with nematic phase liquid crystal mixture, the composition of nematic phase liquid crystal mixture is shown in Table 1) and photoinitiator Irgacure651 are evenly mixed, as the ultraviolet polymerizable monomer liquid crystal composite system, the addition amount of photoinitiator is liquid crystalline ultraviolet 6% of the total mass of the photopolymerizable monomer and the cholesteric liquid crystal mixture; 40% by weight of polythiol curing agent Capcure 3-800 and 60% by weight of E51 containing conjugated epoxy groups Epoxy resin / glycidyl ester ERL-4221 epoxy resin is mixed evenly as a thermal polymerization composite system; the thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com