A kind of preparation method of trans polymer dispersed liquid crystal film

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve problems such as difficulties in process production, affecting product economic benefits, and reducing product performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

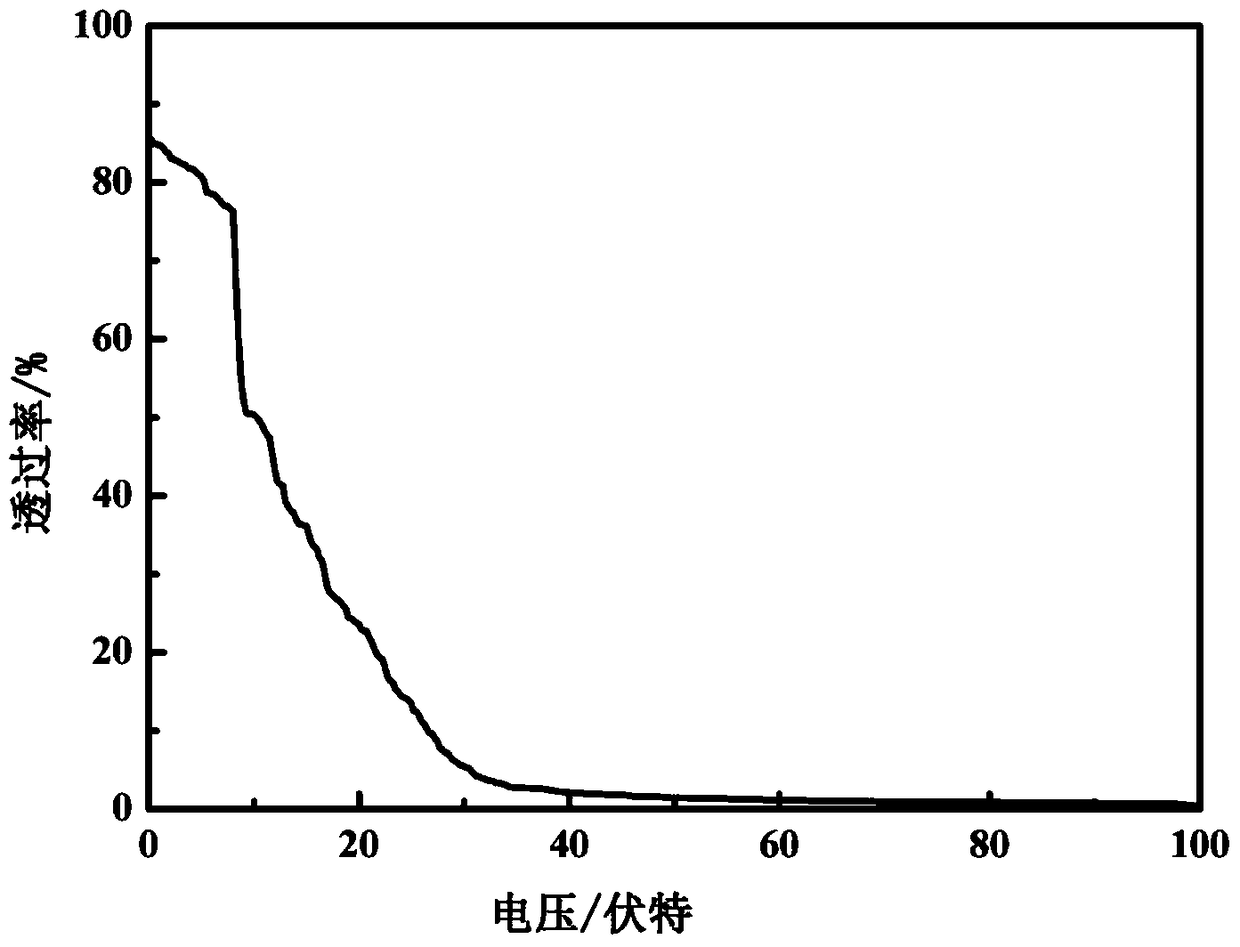

Embodiment 1

[0055] The liquid crystalline ultraviolet light polymerizable monomer (compound 1) that is 1wt% by weight and the negative nematic phase liquid crystal mixture that is 99wt% by weight (select the composition of negative nematic phase liquid crystal mixture in the present invention as shown in Table 1 ) and the photoinitiator Irgacure651 are evenly mixed, as the UV polymerizable monomer liquid crystal composite system, the addition of the photoinitiator is 5% of the total mass of the liquid crystal UV polymerizable monomer and the nematic liquid crystal mixture; the weight percentage is 50% of polythiol type curing agent Capcure 3-800 is mixed with 50% by weight of E51 epoxy resin / glycidyl ester ERL-4221 epoxy resin containing conjugated epoxy groups, as a thermal polymerization compound system; the thermal polymerization composite system and the ultraviolet polymerizable monomer liquid crystal composite system are uniformly mixed at a mass ratio of 2:8 to form an isotropic liqu...

Embodiment 2

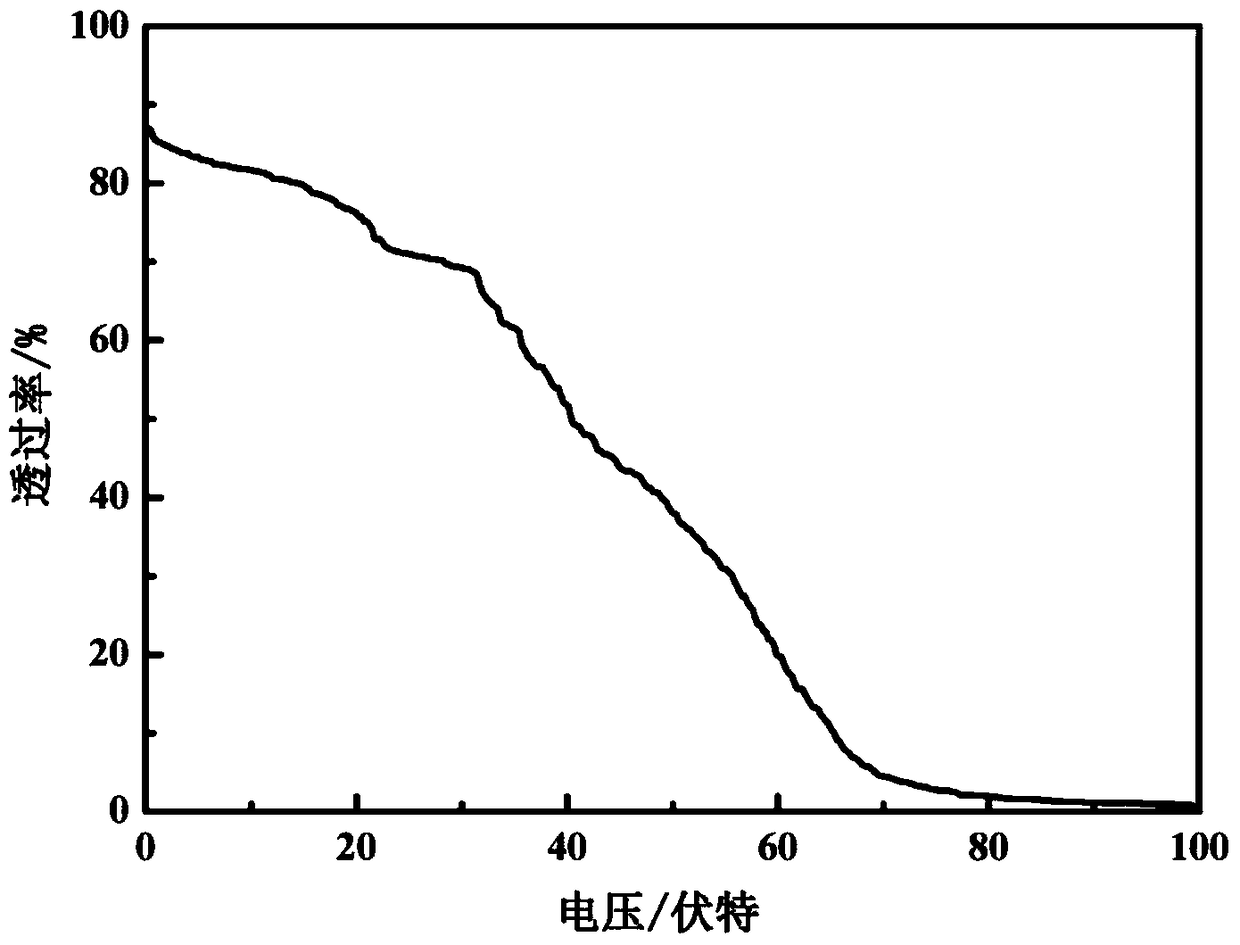

[0062] The liquid crystalline ultraviolet light polymerizable monomer (compound 2) that is 3wt% by weight and the negative nematic phase liquid crystal mixture that is 97wt% by weight (the composition of the negative nematic phase liquid crystal mixture selected in the present invention is as shown in Table 1 Shown) and the photoinitiator Irgacure651 are evenly mixed, as the ultraviolet polymerizable monomer liquid crystal composite system, the addition amount of the photoinitiator is 0.01% of the total mass of the liquid crystal ultraviolet photopolymerizable monomer and the nematic liquid crystal mixture; 20% polythiol type curing agent Capcure 3-800 and 80% by weight thermal polymerizable monomer (compound a) are uniformly mixed as thermal polymer composite system; thermal polymer composite system and UV polymerizable monomer liquid crystal The composite system is uniformly mixed at a mass ratio of 6:4, and forms an isotropic liquid at a temperature of 60°C. A thermal curin...

Embodiment 3

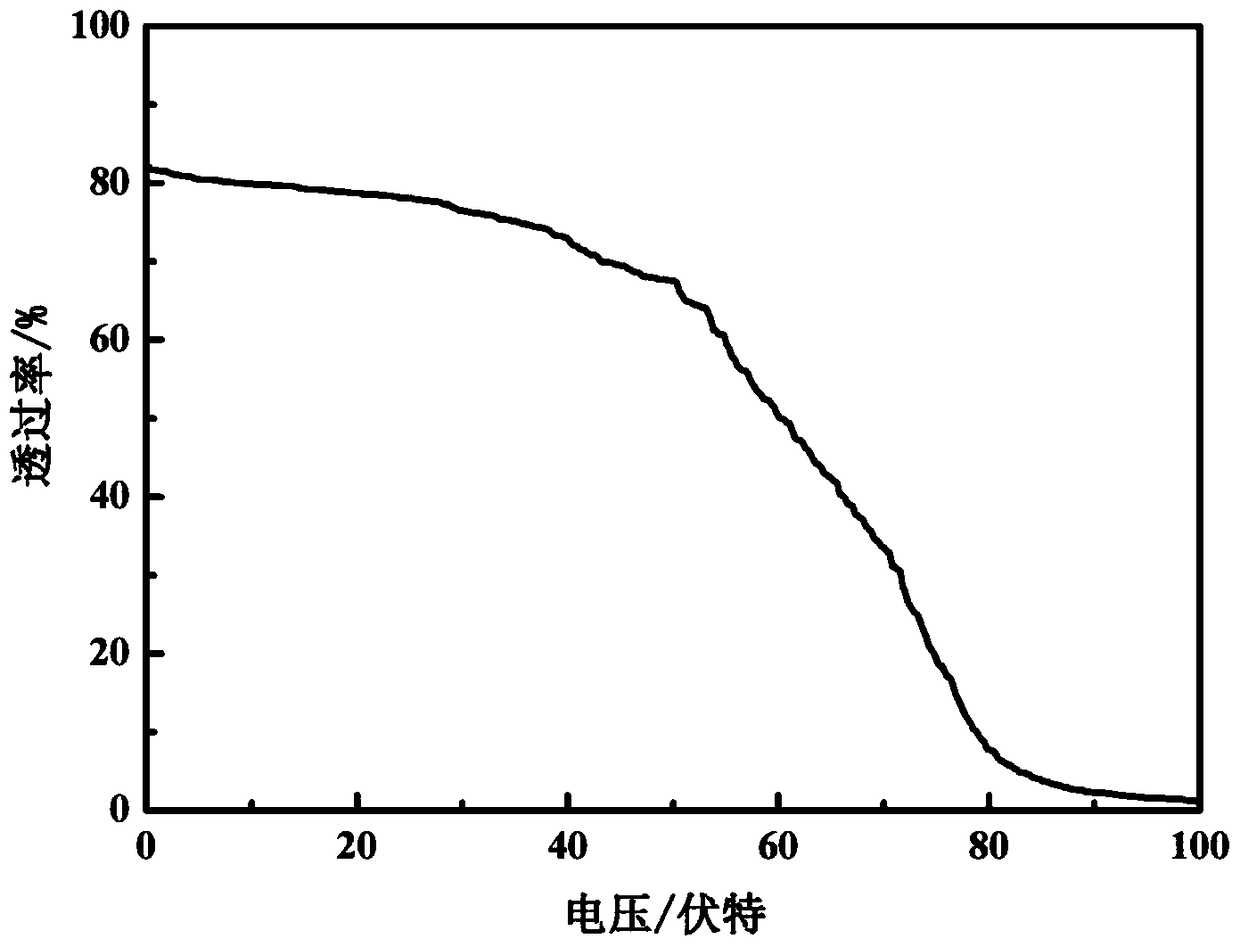

[0065] The liquid crystal ultraviolet light polymerizable monomer (compound 3) that is 4wt% by weight and the negative nematic phase liquid crystal mixture that is 96wt% by weight (the composition of the negative nematic phase liquid crystal mixture selected in the present invention is as shown in Table 1 Shown) and the photoinitiator Irgacure651 are evenly mixed, as the ultraviolet polymerizable monomer liquid crystal composite system, the addition amount of the photoinitiator is 6% of the total mass of the liquid crystal ultraviolet photopolymerizable monomer and the nematic liquid crystal mixture; 40% polythiol type curing agent Capcure 3-800 and 60% by weight thermally polymerizable monomer (compound b) are uniformly mixed as a thermally polymerizable composite system; The composite system is uniformly mixed at a mass ratio of 5:5, and forms an isotropic liquid at a temperature of 70°C. A thermal curing accelerator is added to the isotropic liquid to form a mixed system, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com