Chuck working table and cleaning device

A technology of chuck workbench and cleaning device, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., and can solve problems such as deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

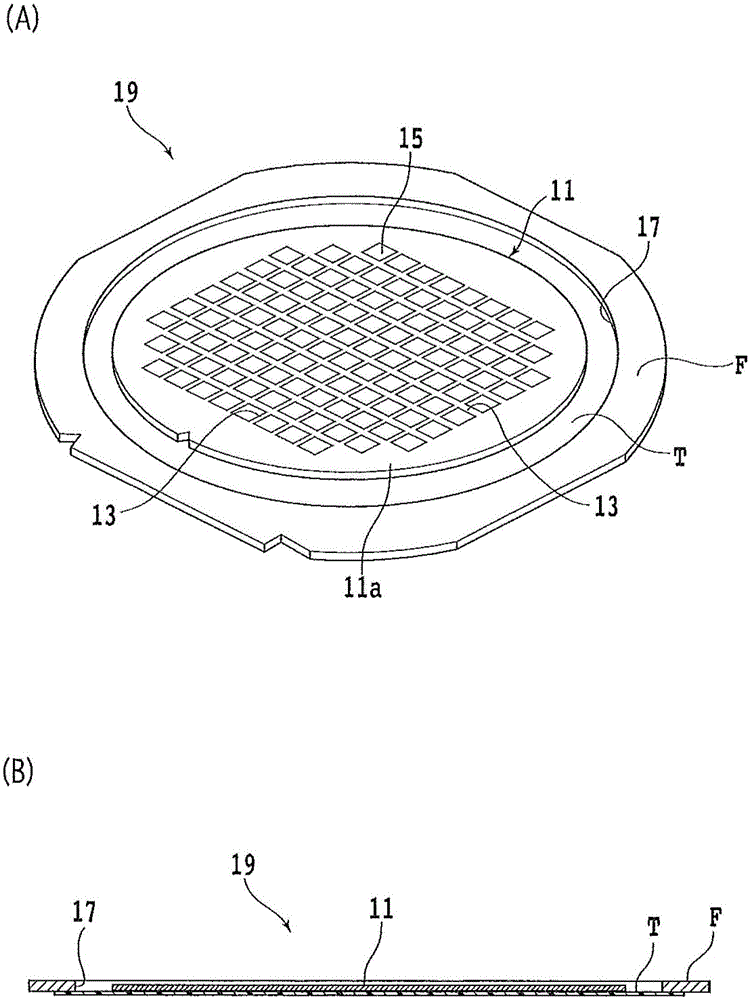

[0019] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. when referring to figure 1 (A), a perspective view of the wafer unit 19 is shown. figure 1 (B) is a sectional view of the wafer unit 19 .

[0020] On the front surface of a semiconductor wafer (hereinafter simply referred to as a wafer) 11, a plurality of dividing lines (streets) 13 are formed in a grid pattern, and devices 15 such as ICs and LSIs are formed in each area divided by the dividing lines 13. .

[0021] The wafer unit 19 is configured such that the back surface of the wafer 11 is bonded to a dicing tape T serving as an adhesive tape, and the outer peripheral portion of the adhesive tape is bonded to the ring frame F so as to cover the opening 17 of the ring frame F. That is, in the wafer unit 19 , the wafer 15 is supported by the ring frame F via the dicing tape T. As shown in FIG.

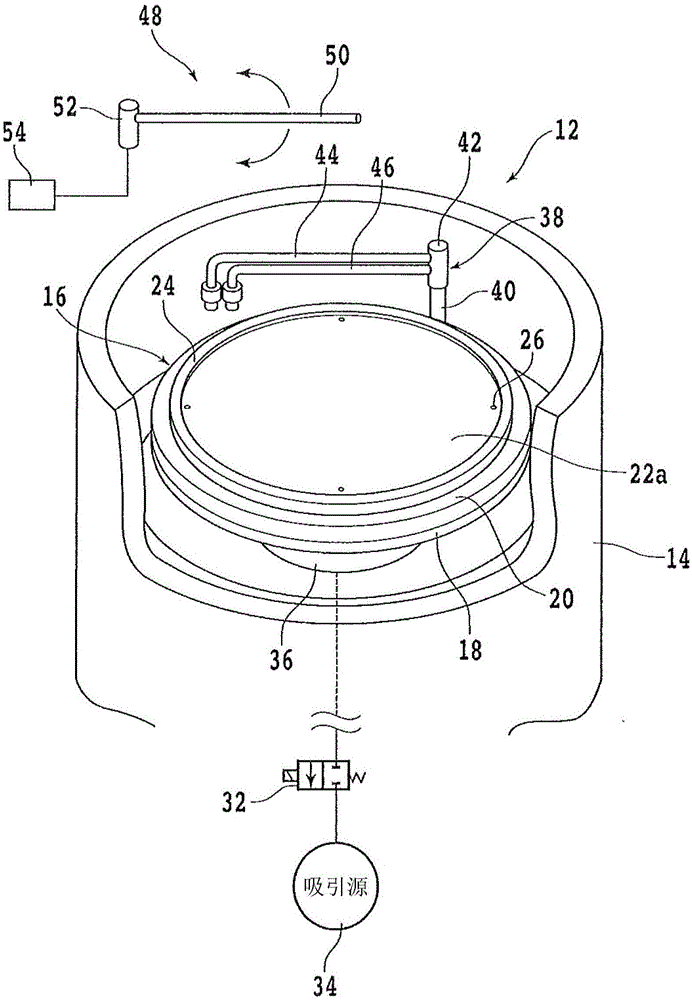

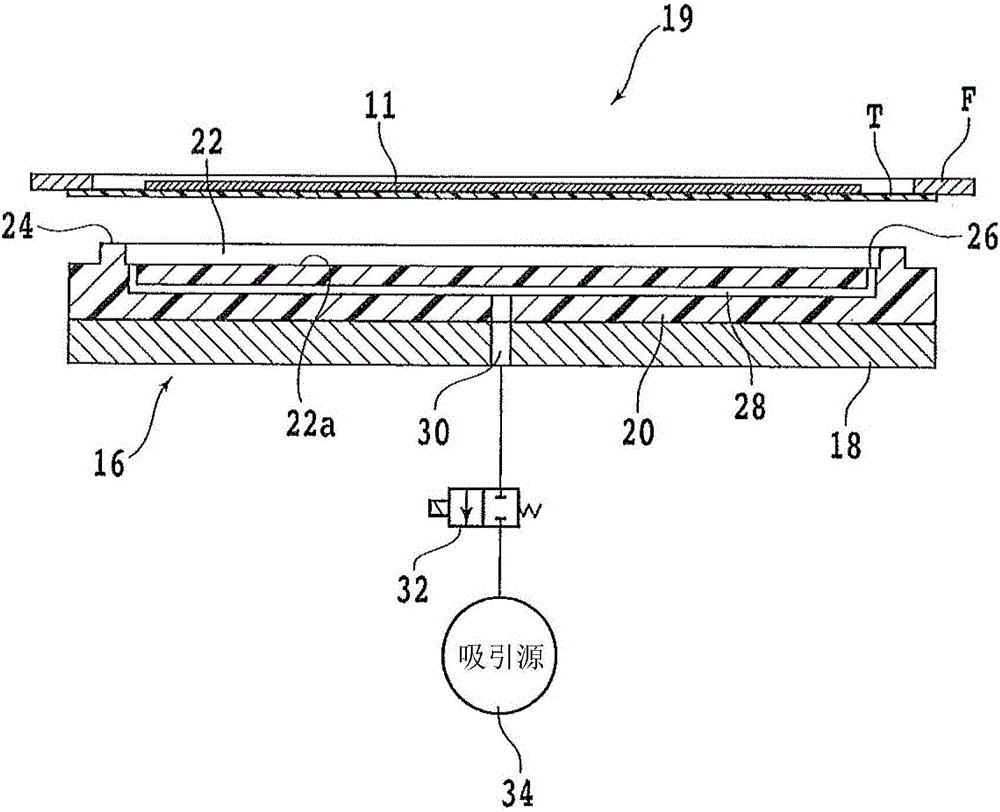

[0022] refer to figure 2 , shows a partially cutaway perspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com