A three-electrode lithium-air battery test mold

A lithium-air battery and testing mold technology, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, measuring electricity, measuring devices, etc., can solve pressure controllability limitations, unevenness, and battery failure Further improvement and other issues to achieve the effect of meeting the gas contact requirements and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing

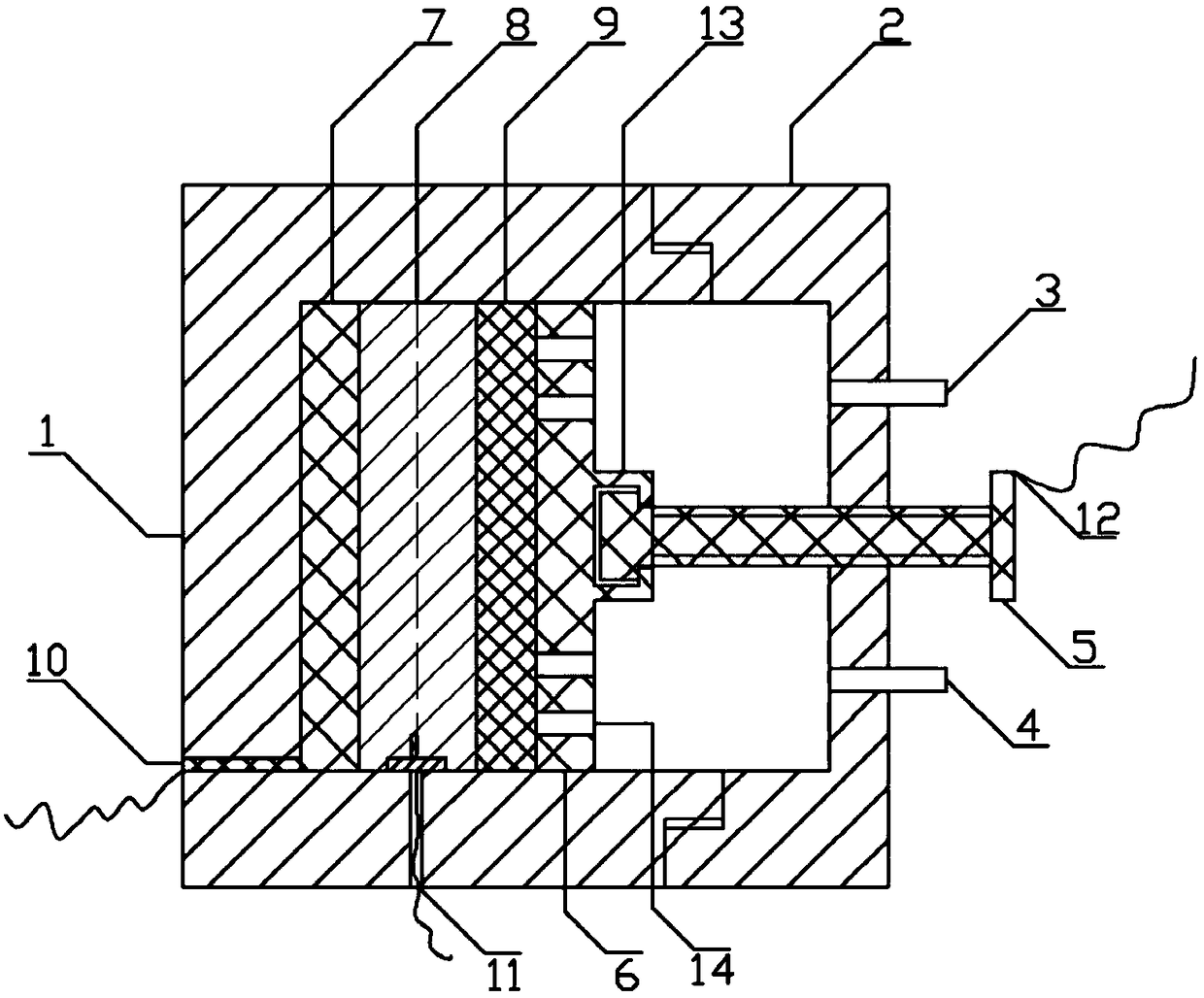

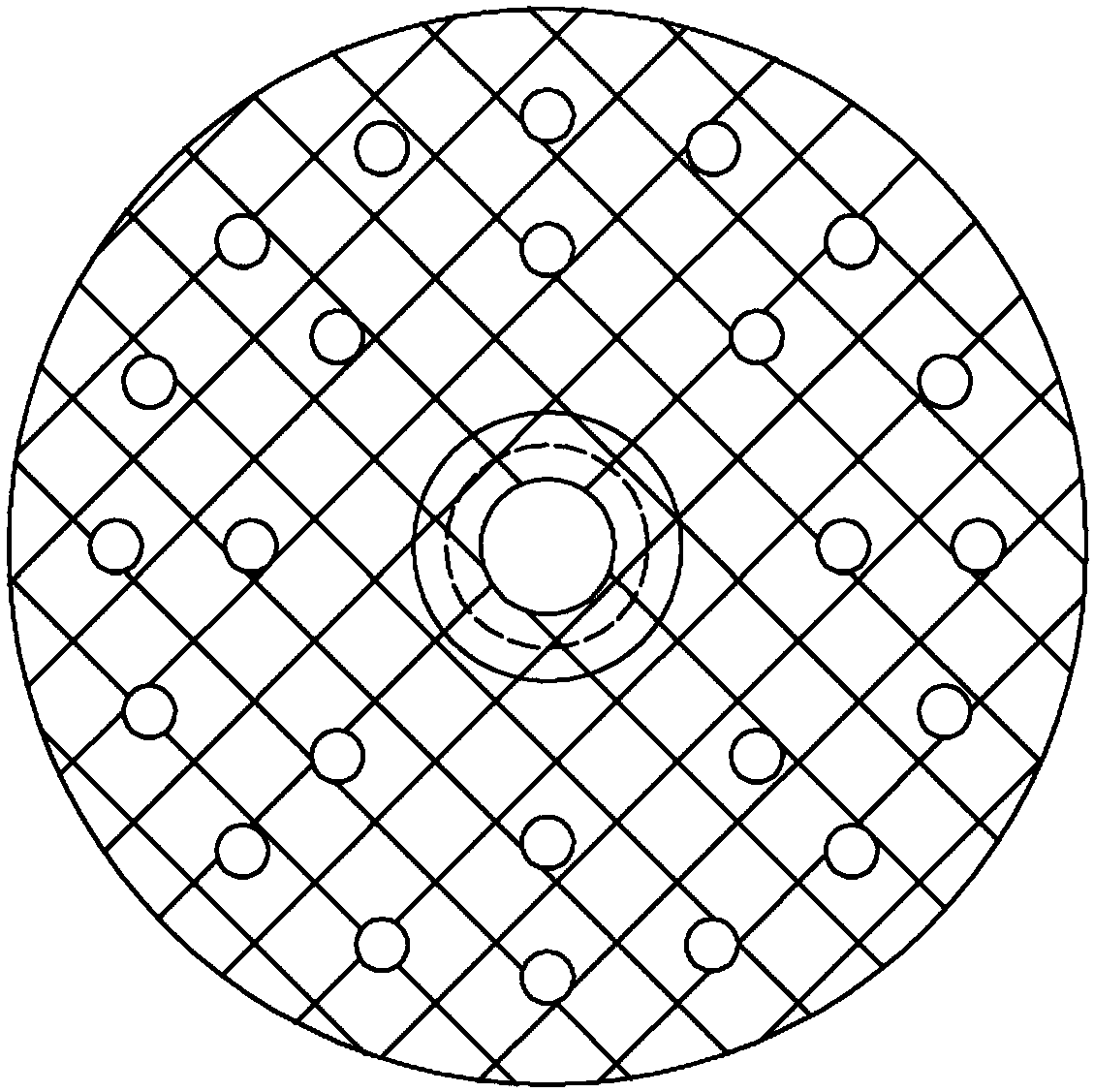

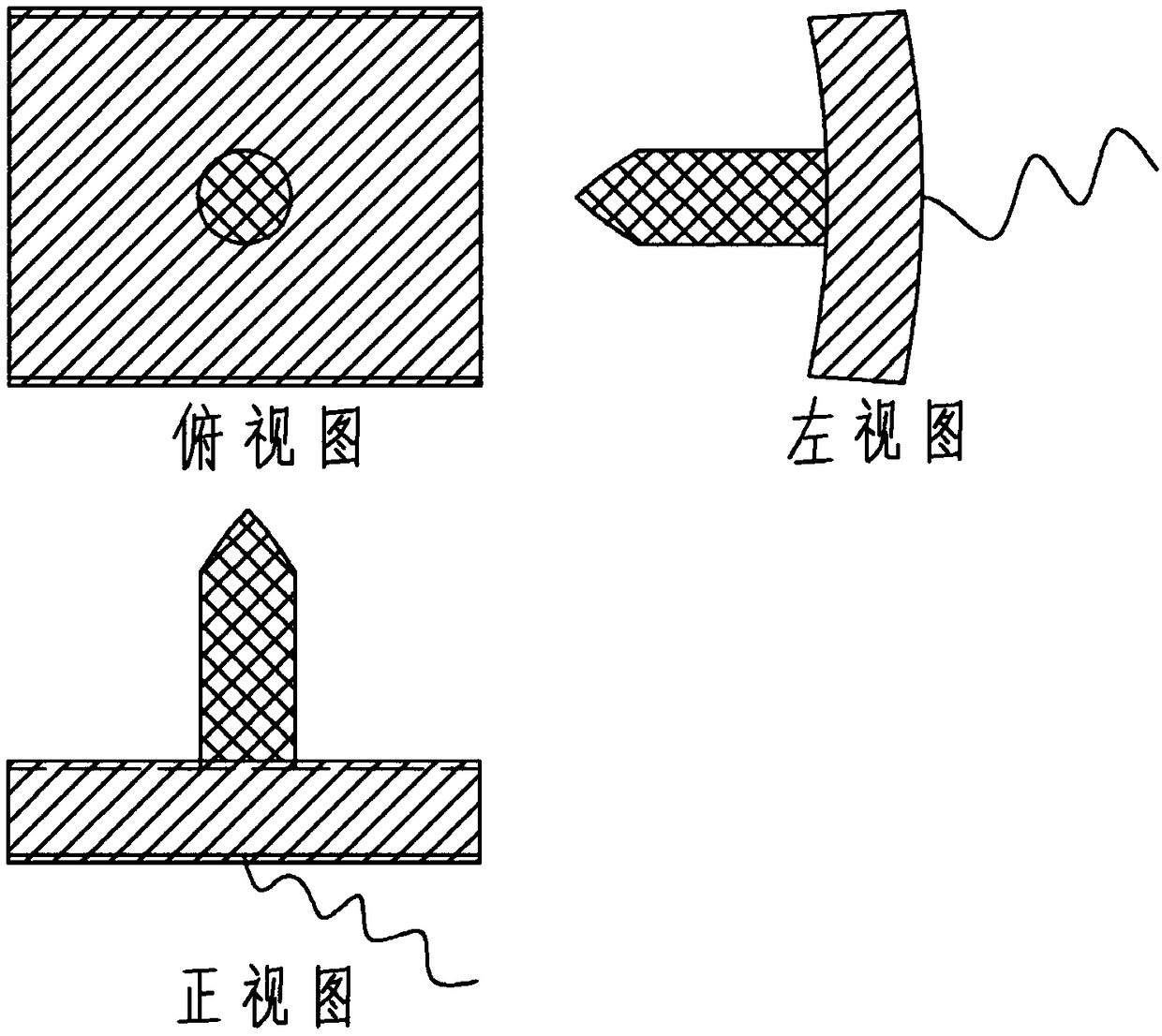

[0031] like figure 1 As shown, the structure of a three-electrode lithium-air battery test mold device of the present invention is: 1, housing a, 2, housing b, 3, air inlet, 4, air outlet, 5, a control rod with threads , 6. Positive electrode case with constriction and ventilation hole, 7. Lithium sheet, 8. Diaphragm, 9. Material to be tested, 10. Negative electrode lead wire, 11. Reference electrode and lead wire, 12. Positive electrode lead wire, 13, Neck, 14, ventilating circular hole.

[0032] 1 Place the case a with the opening facing up.

[0033] 2 Put the lithium sheet into the case a with the negative electrode lead.

[0034] 3 Place a glass fiber separator over the lithium sheet and drop in the electrolyte.

[0035] 4. Lead one end of the lead wire of the reference electrode 11 out from the small hole inside the housing a and place the end with the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com