High reflective mirror laser backscatter measurement device

A measuring device and high reflective mirror technology, which is applied in the measurement of scattering characteristics, can solve the problems that have not been found in reports or literature, and achieve the effect of simple structure, low cost and improved measurement error

Inactive Publication Date: 2012-10-31

XIAN TECH UNIV

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The project team of this invention has searched domestic and foreign patent documents and published journal papers, and has not found any reports or documents closely related to the present invention.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Login to View More

Abstract

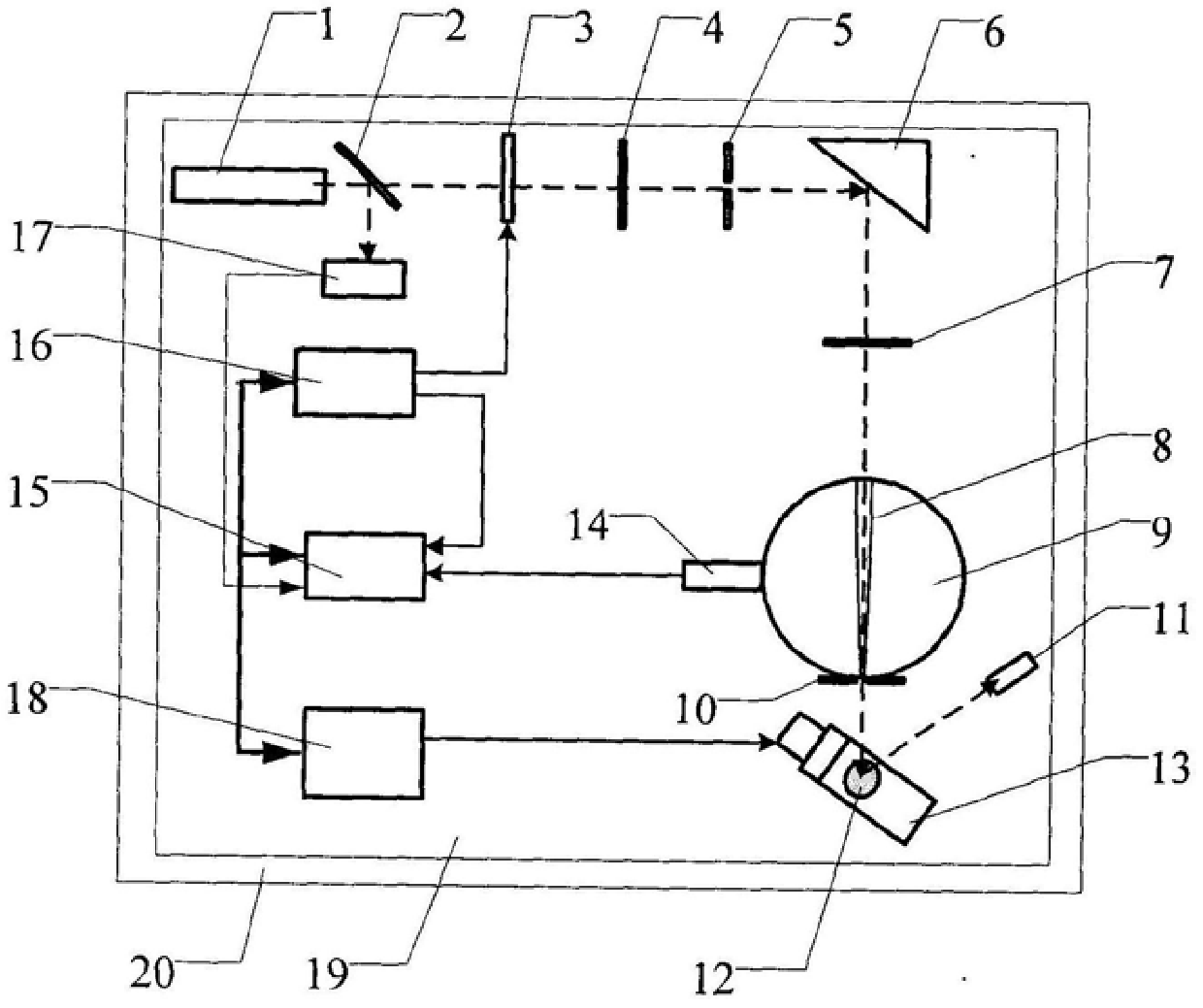

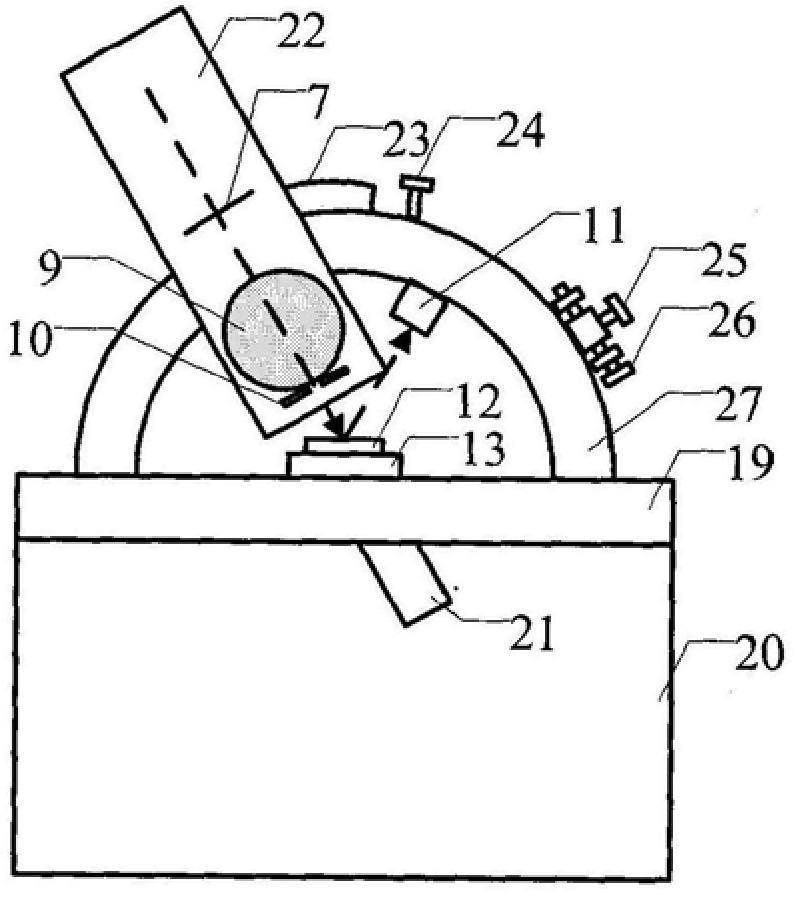

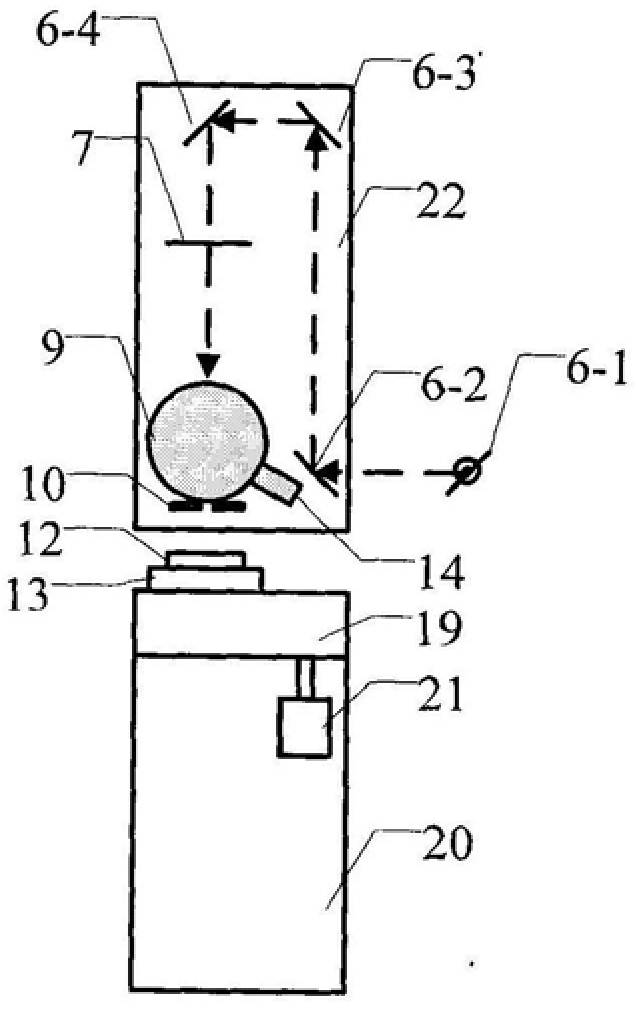

The utility model relates to a laser backscattering measurement device of a high reflection mirror, which belongs to the field of laser gyroscope testing. Split the laser light, detect the reflected light in real time to obtain the fluctuation information of the laser power, and send it to the differential end of the lock-in amplifier to deduct the influence of the light source fluctuation on the measured value; after the transmitted light is modulated and the optical components are adjusted, it is incident at an adjustable angle When it reaches the surface of the high reflector to be tested, the reflected light is absorbed by the light trap, and the backscattered light with the incident light as the optical axis is collected by the integrating sphere through a small hole solid angle, and converted into an electrical signal and sent to the differential end of the lock-in amplifier The second is sent to the computer through lock-in amplification processing. The measured sample moves with the computer-controlled electric console to complete the measurement of backscattered light intensity at different points, and obtains a two-dimensional distribution map. The problem of difficult measurement of weak backscattered light intensity is solved. It realizes the accurate measurement and automatic measurement of laser backscattering of high reflective mirrors, and can also measure the backscattering of high reflective mirrors or ultra-smooth surfaces for other purposes. It can be widely used in laser gyroscope production and scientific research.

Description

High reflective mirror laser backscatter measurement device technical field The invention belongs to the technical field of laser gyro testing, and relates to backscattering measurement of a high reflection mirror used in a laser gyro resonator cavity, in particular to a laser backscattering measurement device for a high reflection mirror. Background technique A typical laser gyro system has a polygonal (usually regular quadrilateral) optical resonant cavity. The high reflection mirror is the key optical component of the resonant cavity, and its reflectivity is generally as high as 99.99%. The two beams of light waves propagating counterclockwise in the resonator are not coupled to each other. The rotation of the laser system causes a Doppler frequency difference between the two beams of light waves. The difference is proportional to the rotation speed. Using this principle to Measure the angular rotational velocity to obtain the precise coordinates of the spatial position...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N21/47

Inventor 刘卫国高爱华徐昌杰秦文罡弥谦杭凌侠

Owner XIAN TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com