Freeze-drying method of Cordyceps sinensis

A technology of Cordyceps sinensis and drying method, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., which can solve the problems of difficulty in realizing industrial production and small scale, and achieve energy saving, reduction of breakage rate, and improvement of freezing The effect of dry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

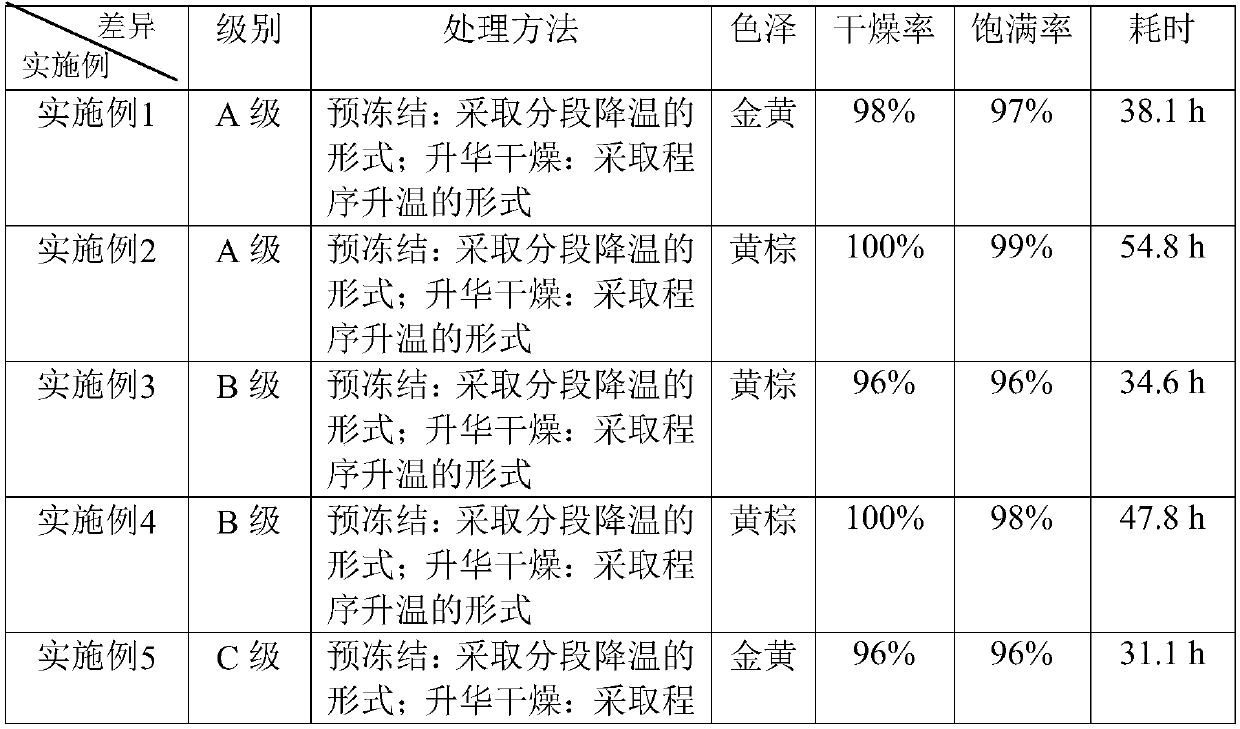

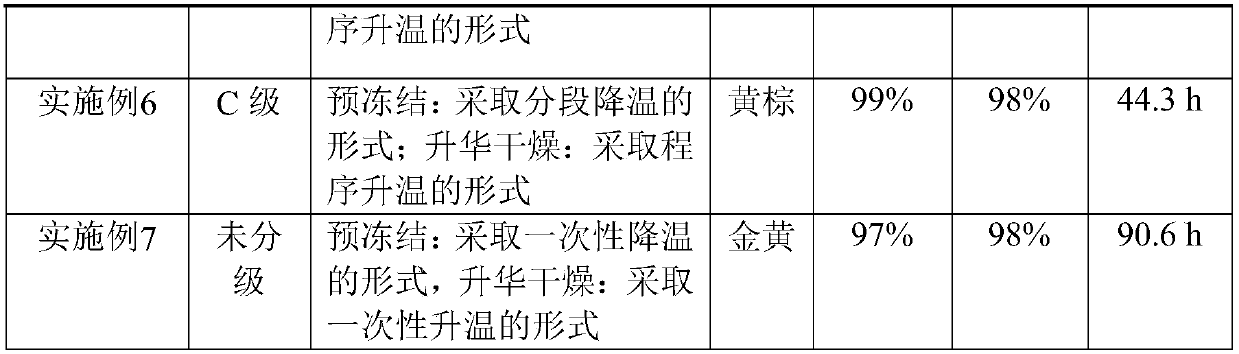

Embodiment 1

[0042] The present embodiment adopts the LYO-2 type freeze dryer of Shanghai Tofflon Science and Technology Co., Ltd. to freeze-dry the fresh Cordyceps sinensis of grade A below 800 per kilogram of 10kg, and the method is as follows:

[0043] (1) Pre-freezing: the harvested and cleaned fresh A-grade Cordyceps sinensis is cooled in stages from room temperature to -40°C, and the staged cooling procedure is: cool down from room temperature to -10°C within 0.5 hours ; Then cool down from -10°C to -25°C within 0.5h; finally cool down from -25°C to -40°C within 0.5h, and keep for 6h;

[0044] (2) Sublimation drying: The heating time of the shelf is 0.5h, so that the temperature of the shelf is raised from -40°C to -10°C, and then the sublimation drying is carried out in the form of temperature programming, and the temperature is raised from -10°C to -6°C. The temperature programming form is: the shelf temperature is -10°C, adjust the pressure to 35Pa, maintain for 1h, then adjust to...

Embodiment 2

[0049] In this embodiment, the LYO-2 type freeze dryer of Shanghai Tofflon Science and Technology Co., Ltd. was used to freeze-dry the fresh Cordyceps sinensis of A grade of 10kg below 800 / kg.

[0050] The difference with embodiment 1 is:

[0051] Step (1) Pre-freezing: The temperature is lowered from room temperature to -40°C in the form of segmental cooling, and the segmental cooling program is: cooling to -10°C within 0.5h; then cooling from -10°C within 0.5h to -25°C; cool down from -25°C to -40°C within the last 0.5h, and maintain for 8h;

[0052] Step (2) Sublimation drying: The heating time is 0.5h to raise the temperature of the shelf from -40°C to -10°C, and then the sublimation drying is carried out in the form of temperature programming, and the temperature is raised from -10°C to -6°C. The temperature programming form is as follows: shelf temperature -10°C, adjust pressure to 45Pa, maintain for 2h, then adjust to 15Pa, maintain for 4h, and perform 2 cycles; shelf ...

Embodiment 3

[0057] The difference between this example and Example 1 is that this example adopts the LYO-2 type freeze dryer of Shanghai Tofflon Science and Technology Co., Ltd. to freeze-dry 10 kg of B-grade fresh Cordyceps sinensis.

[0058] The temperature program in step (2) is as follows: raise the temperature for 0.5 hours to increase the temperature of the shelf from -40°C to -10°C, adjust the pressure to 30Pa, maintain it for 1h, then adjust it to 10Pa, maintain it for 2.5h, and perform 2 cycles ;The temperature of the shelf is raised to -8°C, adjust the pressure to 30Pa, maintain for 1h, then adjust to 10Pa, maintain for 2.5h, and perform 3 cycles; raise the temperature of the shelf to -6°C, adjust the pressure to 30Pa, maintain for 1h, Then adjust to 10Pa, maintain 2.5h, and carry out 2 cycles.

[0059] Finally, the color of the finished product is yellow-brown, with a drying rate of 96% and a plumping rate of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com