A kind of bagasse-based anionic adsorbent and its preparation method and application

A sugarcane bagasse and anion technology, which is applied in the field of biomass materials and adsorption and separation, can solve the problems of non-single components, difficult to use, environmental pollution, etc., and achieve the effects of high production efficiency, good waste treatment and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

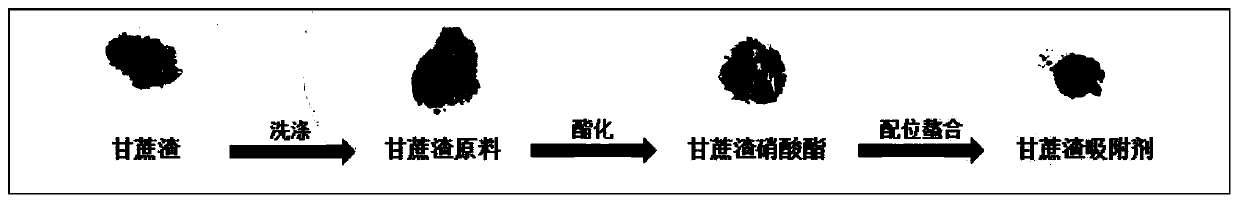

[0034] The preparation of bagasse-based anionic adsorbent, concrete steps are as follows:

[0035] 1) Washing and drying treatment: use discarded bagasse as raw material, first soak it in clean water, wash to remove dirt and dust, then wash it with distilled water, and then dry it to constant weight to make bagasse raw material for future use.

[0036] 2) Esterification reaction: Take 50g bagasse raw material, mix it with 450mL nitric acid (63% by mass) and 150mL glacial acetic acid, stir at 30°C under normal pressure, and perform esterification reaction for 4 hours to obtain bagasse ester.

[0037] 3) Coordination reaction: the bagasse ester obtained in step 2) was mixed with 300mL ferric chloride (6%) solution, stirred at 35°C under normal pressure for 4 hours, and the reaction product was washed with distilled water several times to medium properties, suction filtration, and drying at 35°C to obtain Fe-coordinated modified bagasse-based anion adsorbent (finished adsorbent)....

Embodiment 2

[0047] The preparation of bagasse-based anionic adsorbent, concrete steps are the same as embodiment 1, just change the massfraction of nitric acid used in step 2) esterification reaction to 65%, change step 3) the massfraction of ferric chloride used in coordination reaction The mass fraction was changed to 8%, and the temperature of the coordination reaction was changed to 55°C.

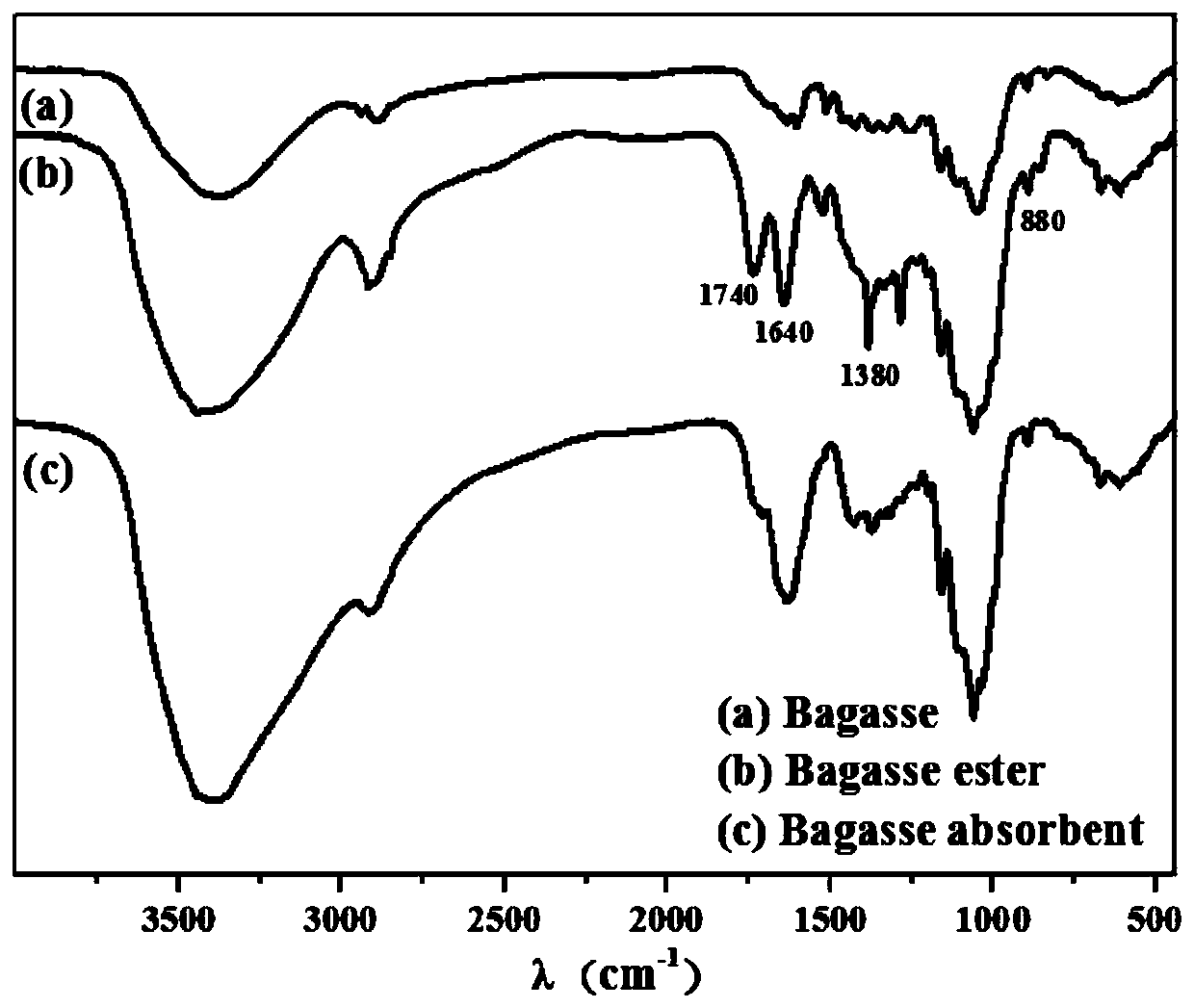

[0048] In the present embodiment, the infrared spectrum comparison chart of the bagasse raw material obtained in step 1), the bagasse nitrate ester obtained in step 2) and the modified bagasse-based anion adsorbent obtained in step 3) are as follows figure 2 shown. Contrast (a), (b) 1700cm -1 Left and right, proving that there are NO groups in nitrate esterification, 1300cm -1 The left and right prove that there is C-N, so the esterification is successful; in the comparison (b), (c) it is found that 1300cm -1 The stretching vibration has been weakened, indicating that the coordination of Fe sho...

Embodiment 3

[0051] The preparation of bagasse-based anionic adsorbent, the specific steps are the same as in Example 1, except that the mass fraction of nitric acid used in step 2) in the esterification reaction is changed to 53%, the volume consumption is changed to 400mL, and the step 3) in the coordination reaction The mass fraction of the ferric chloride used is changed to 4%, and the dosage volume is changed to 250mL.

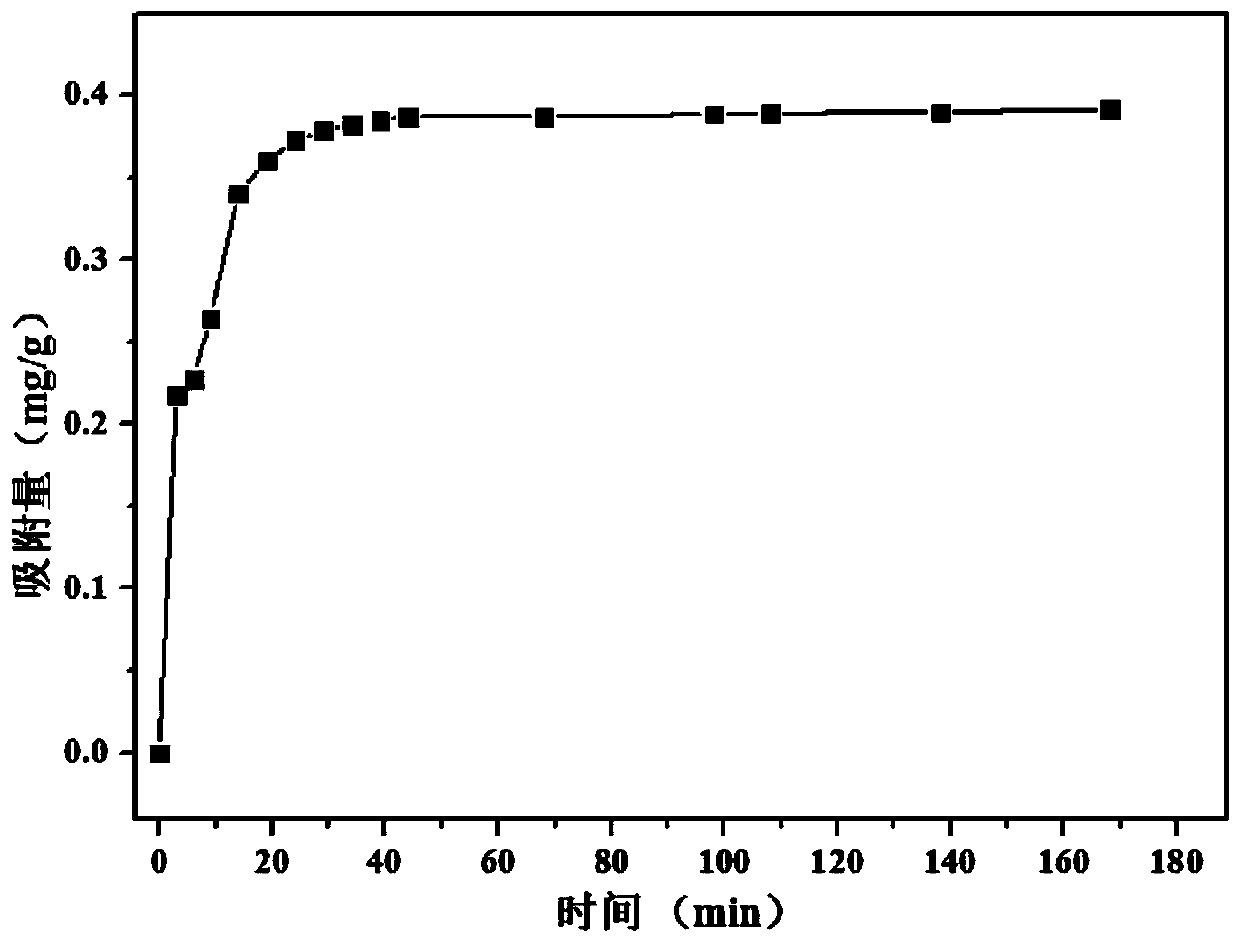

[0052] According to the adsorption performance test method described in Example 1, when 0.5 g of the bagasse-based anion prepared in this embodiment is adsorbed at 25° C. to absorb 80 mL of 5 mg / L phosphate solution, the phosphate solution reaches the peak value within 45 minutes. Adsorption equilibrium, when the adsorption equilibrium is reached, the concentration of the adsorbed phosphate solution is 2.15 mg / L, and the adsorption efficiency is the highest at this time, reaching 57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com