A kind of carbon block cleaning equipment

A technology for cleaning equipment and carbon blocks, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of difficult cleaning of anode carbon blocks, time-consuming and labor-intensive cleaning effects, and easily damaged knives, etc., to achieve Suitable for large-scale promotion and application, saving capital investment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the inventive concept of the present invention, the specific embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings:

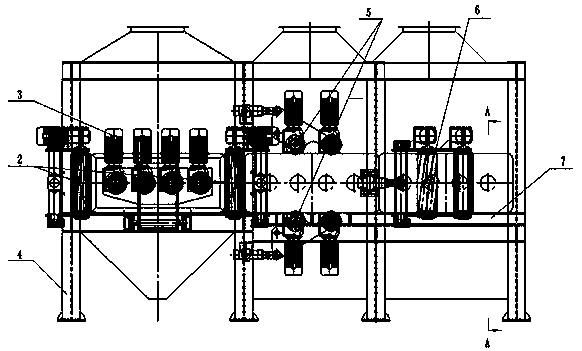

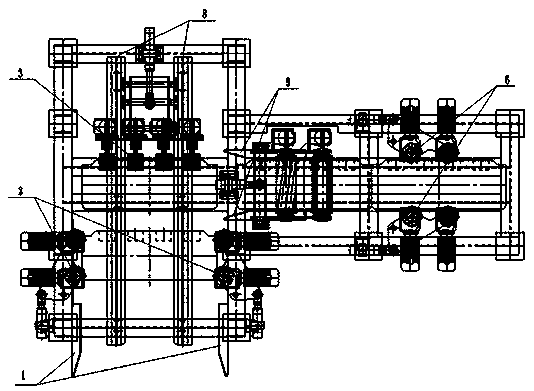

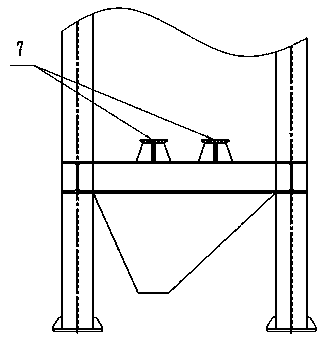

[0029] like Figure 1 to Figure 3 As shown, a kind of carbon block cleaning equipment of the present invention includes a frame 4, a cleaning device, a support rail, a guide rail, and a driving device X, and the support rail and the guide rail are arranged on the frame 4, and the cleaning device is located at On the support track, it is driven by the driving device X to realize its swing, and the carbon block is cleaned during the swing process. The support track includes support track one 7 and support track two 8, and the guide track includes Corresponding guide track one 1 and guide track two 9 of track.

[0030] Further, the cleaning device includes a set of cleaning rollers and three sets of spiral cleaning knives, wherein one set of the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com