Patents

Literature

32results about How to "Simple process configuration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

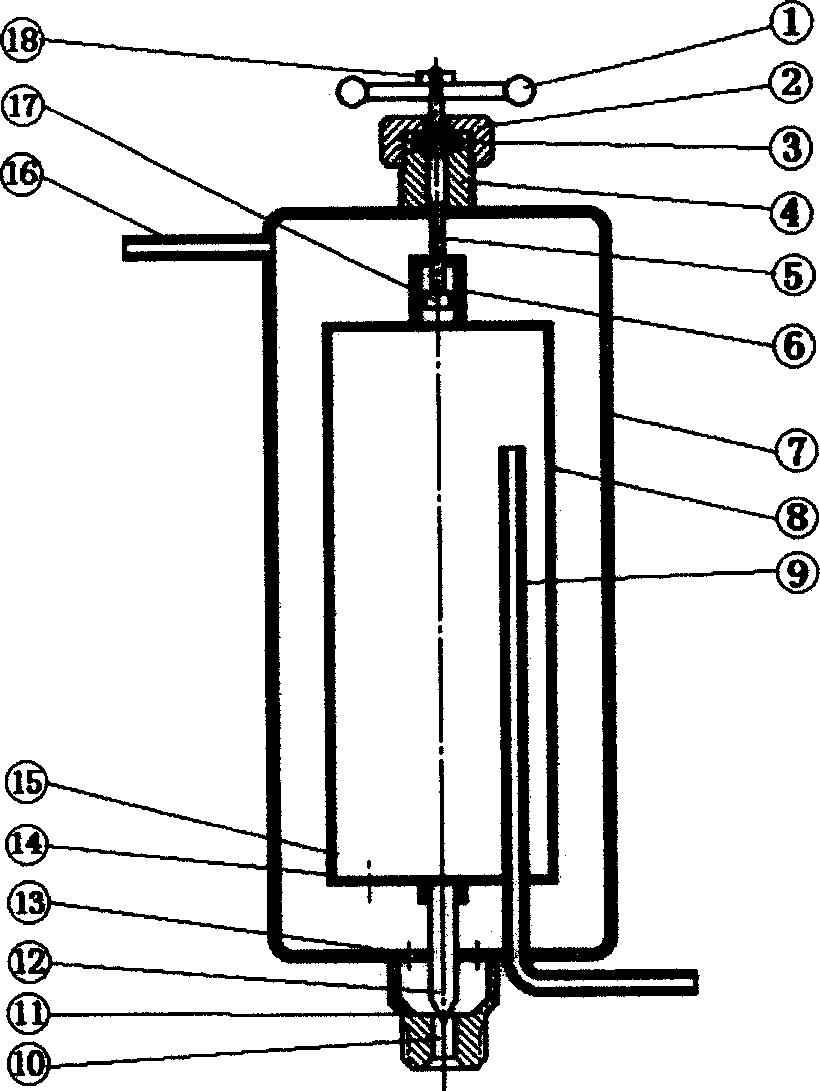

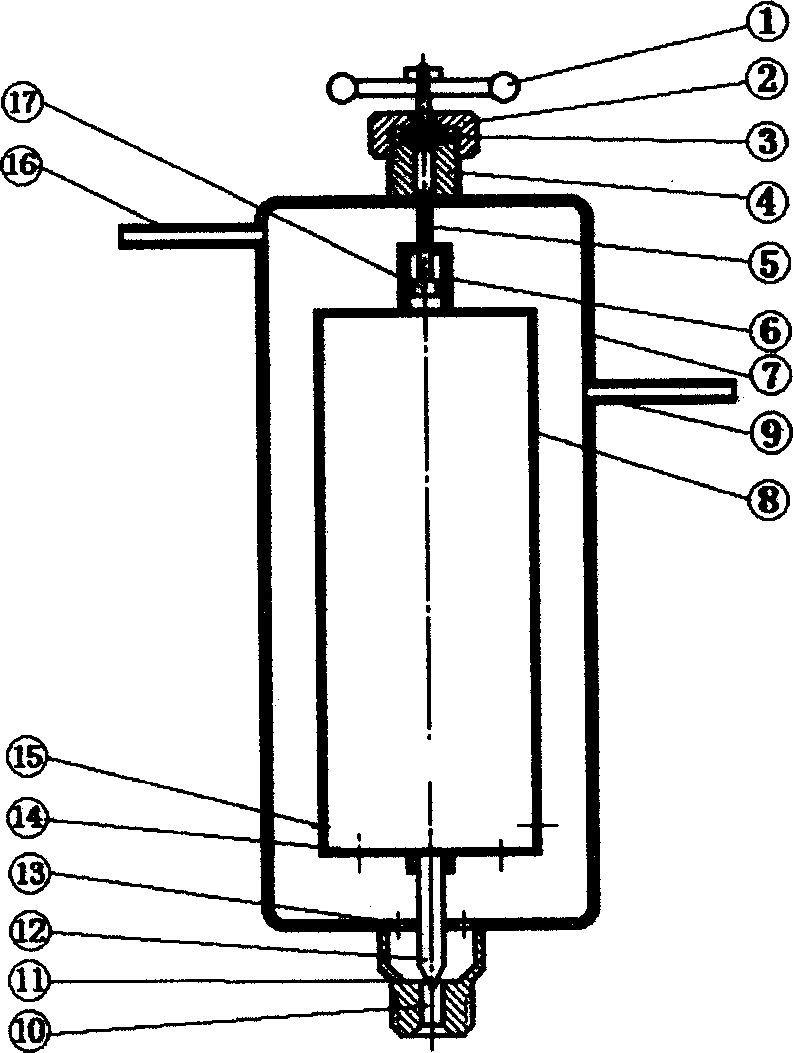

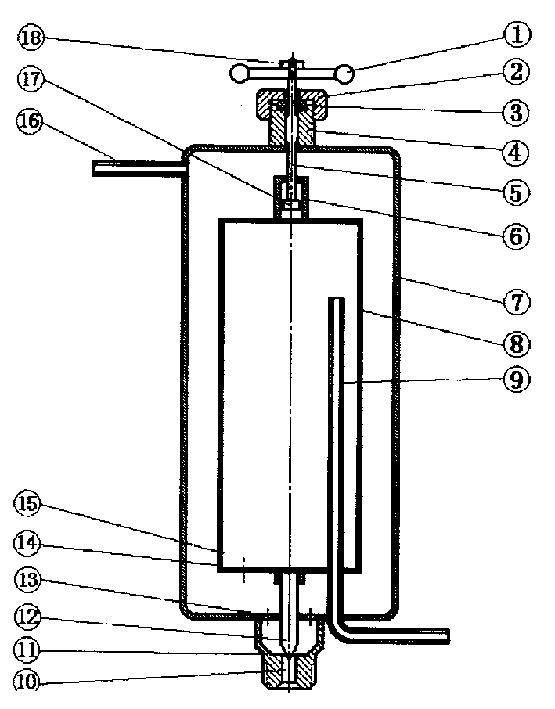

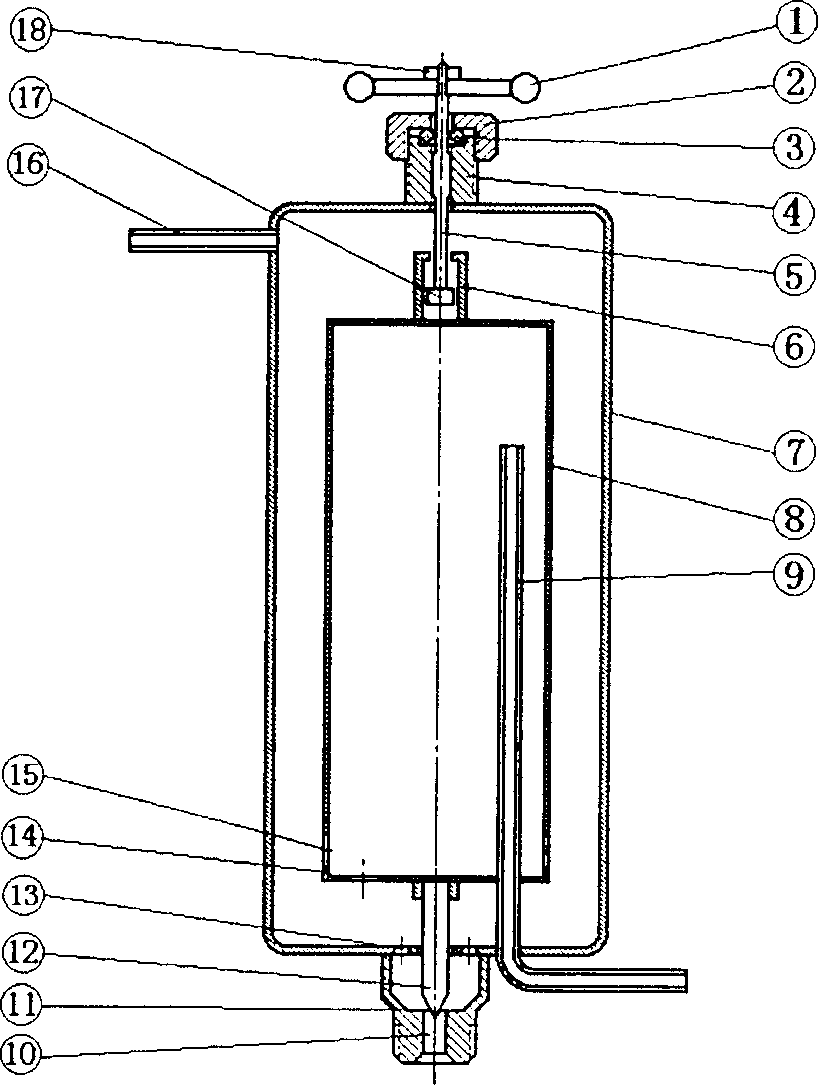

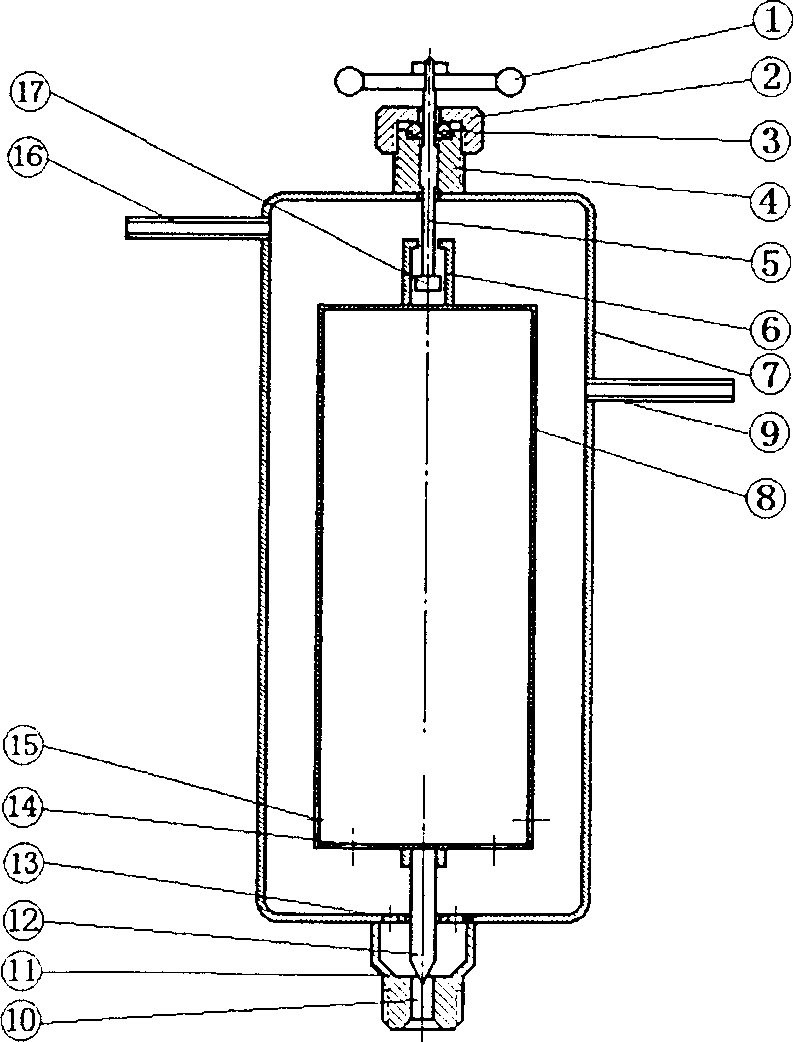

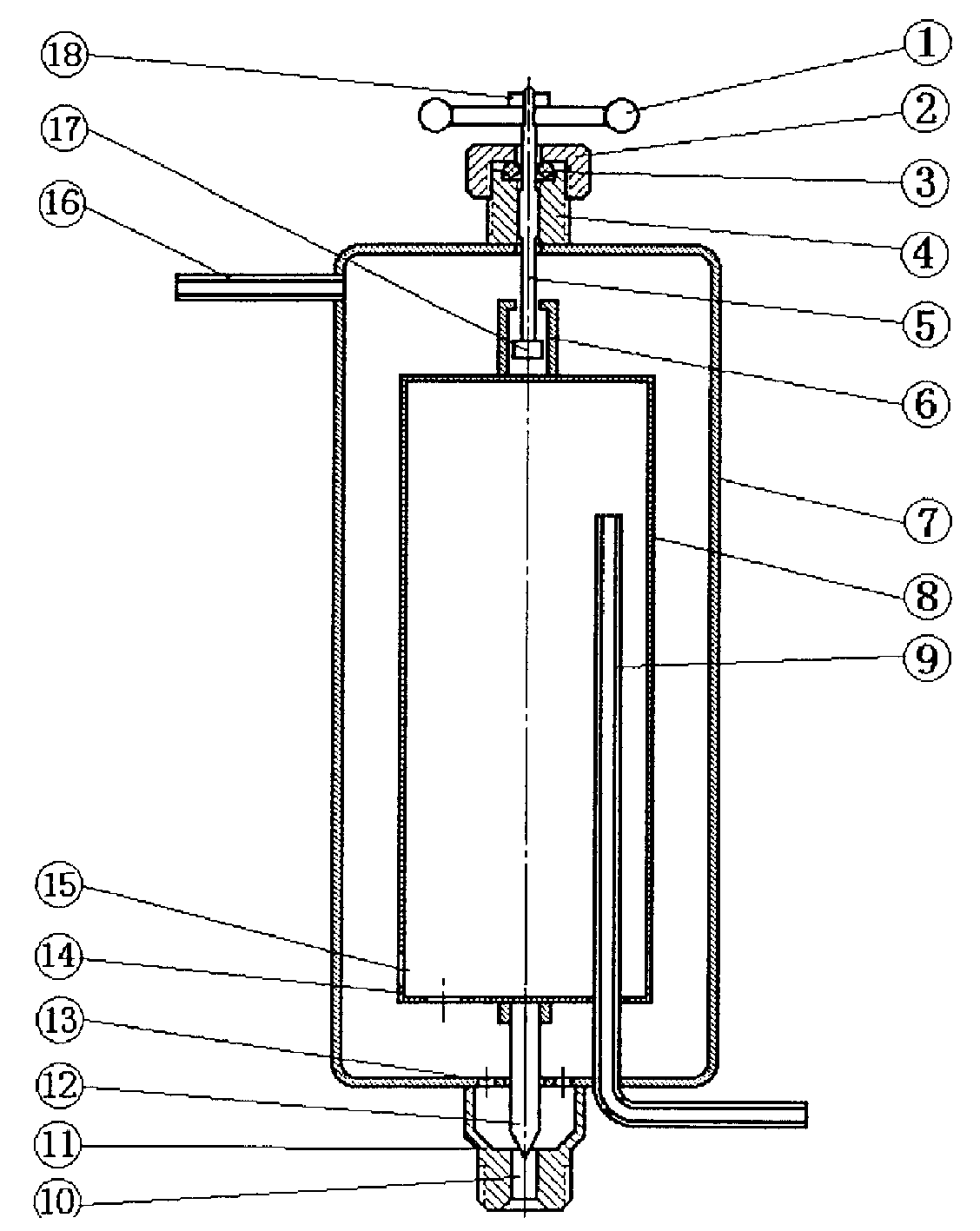

Integrated gas/liquid separating device with automatically controlled liquid level

InactiveCN1457915ASimple structureSmall footprintLiquid degasificationVapor–liquid separatorIntegrated design

The integrated gas / liquid separator with automatically controlled liquid level consists of mainly regulating hand wheel, sealing screw nut, sealing ring, regulating screw sleeve, outer cylinder, floating cylinder, material feeding pipe, liquid draining valve body, liquid draining valve needle rod and gas exhaust pipe. The integrated design of gas / liquid separation and liquid level control results in simple structure, convenient use and no limitation in use pressure, and is especially gas / liquid phase separation in petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

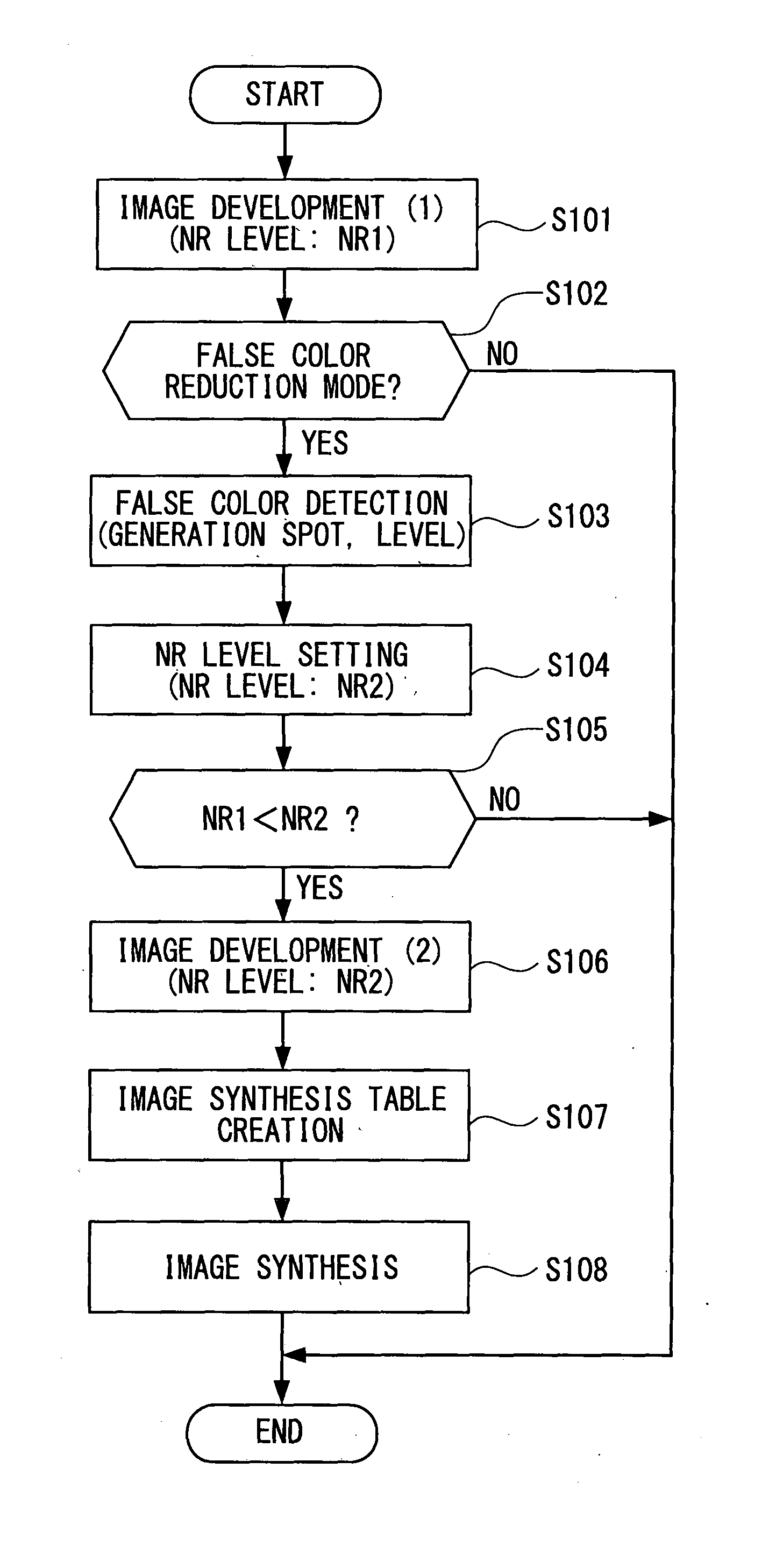

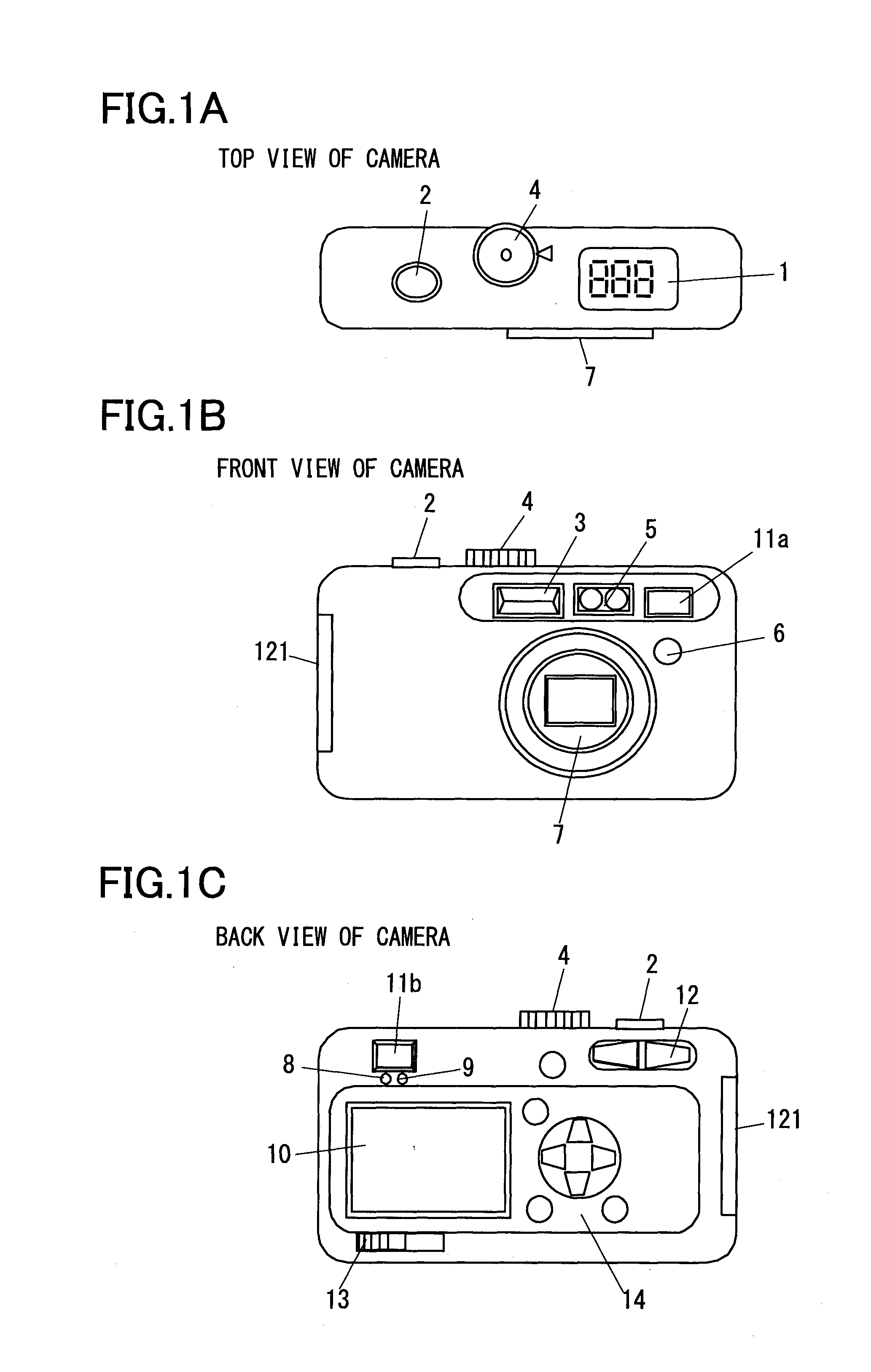

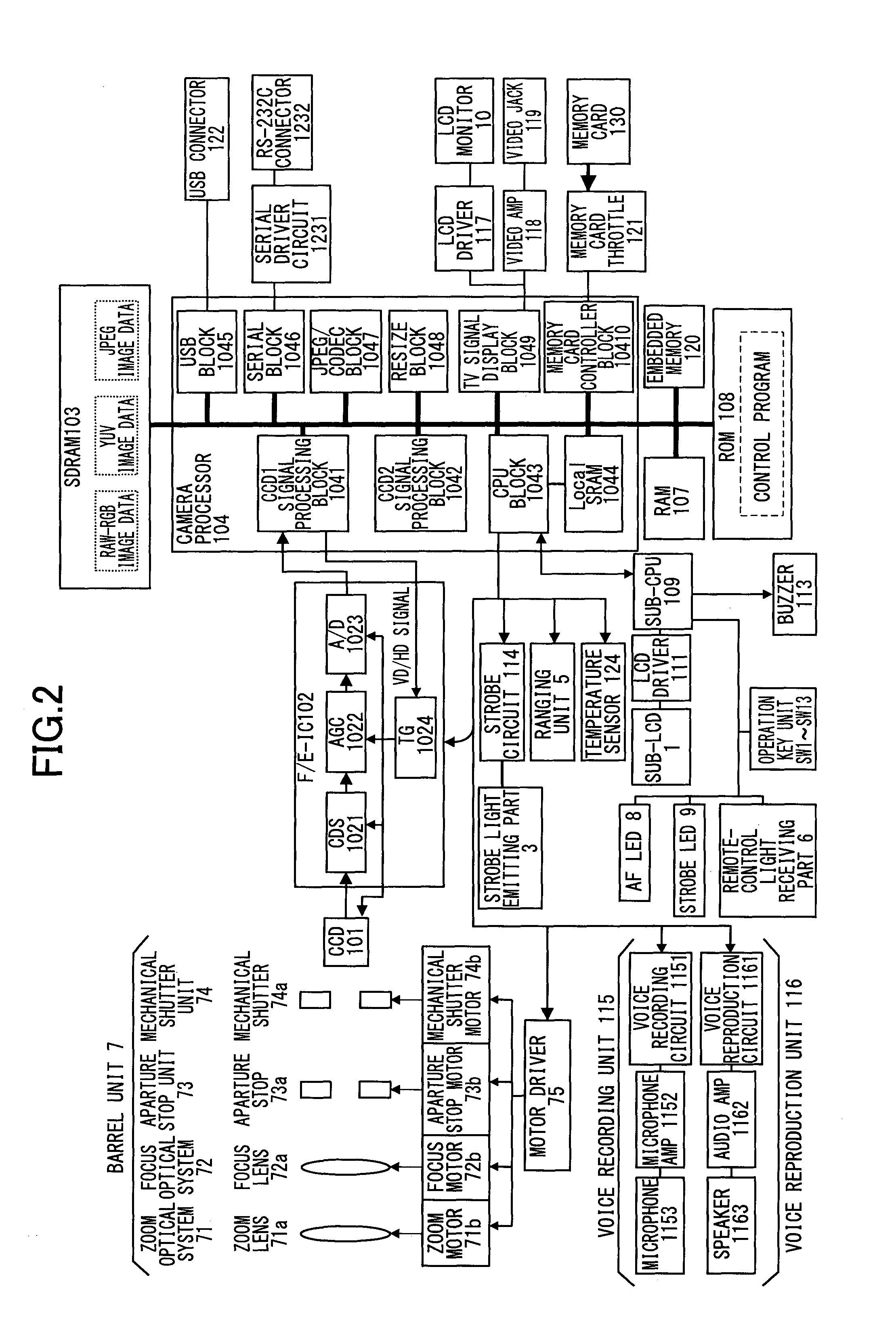

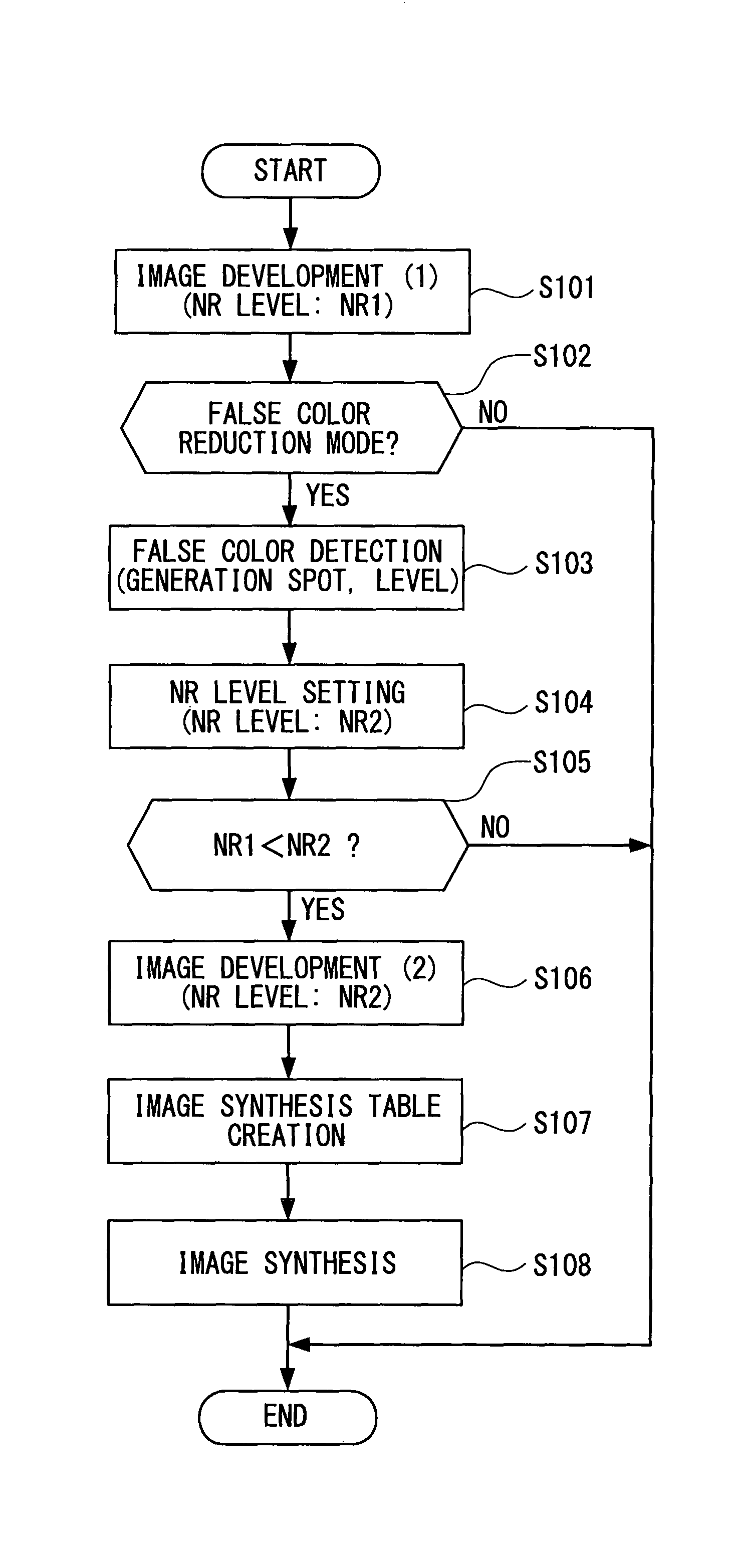

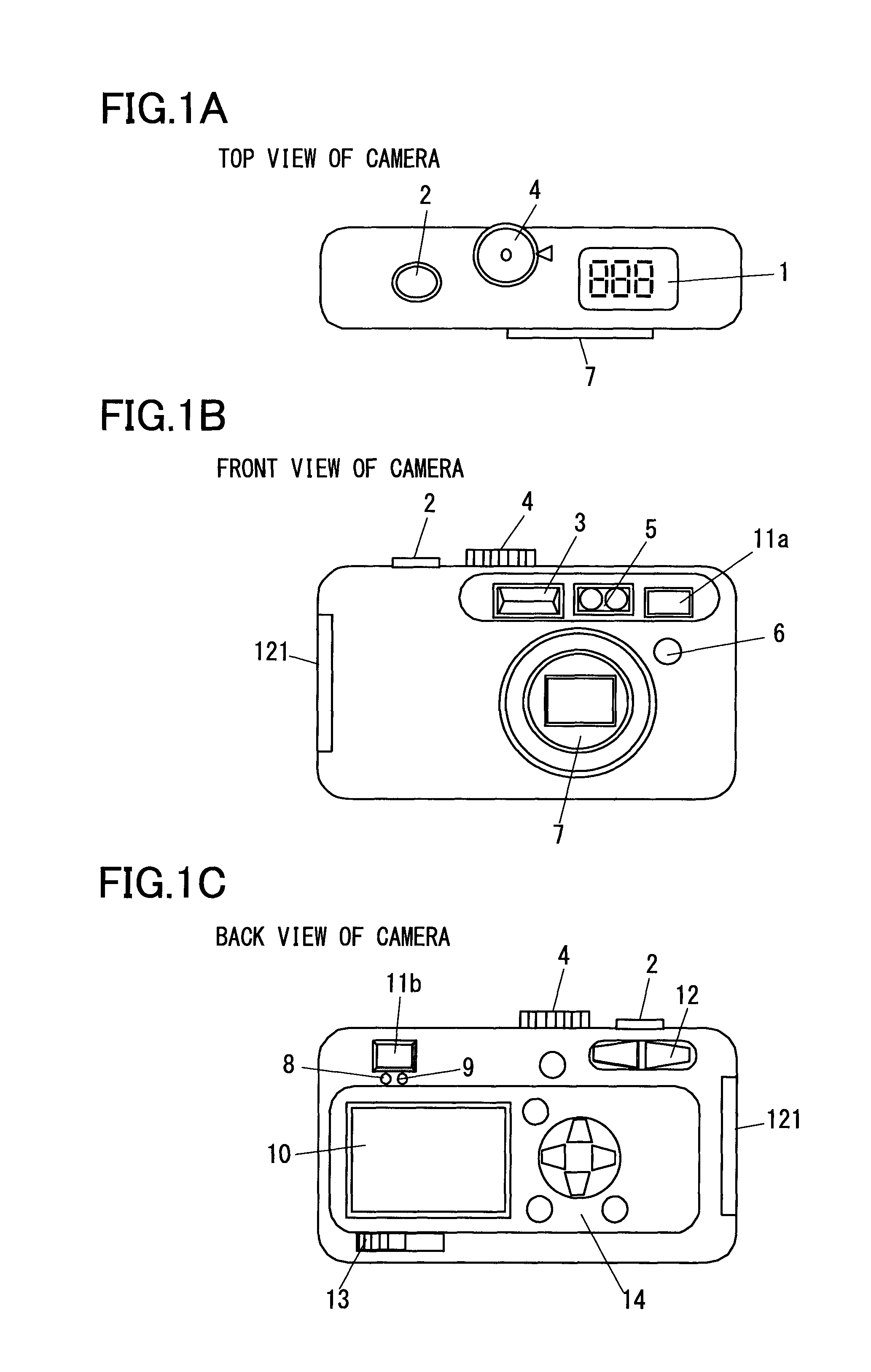

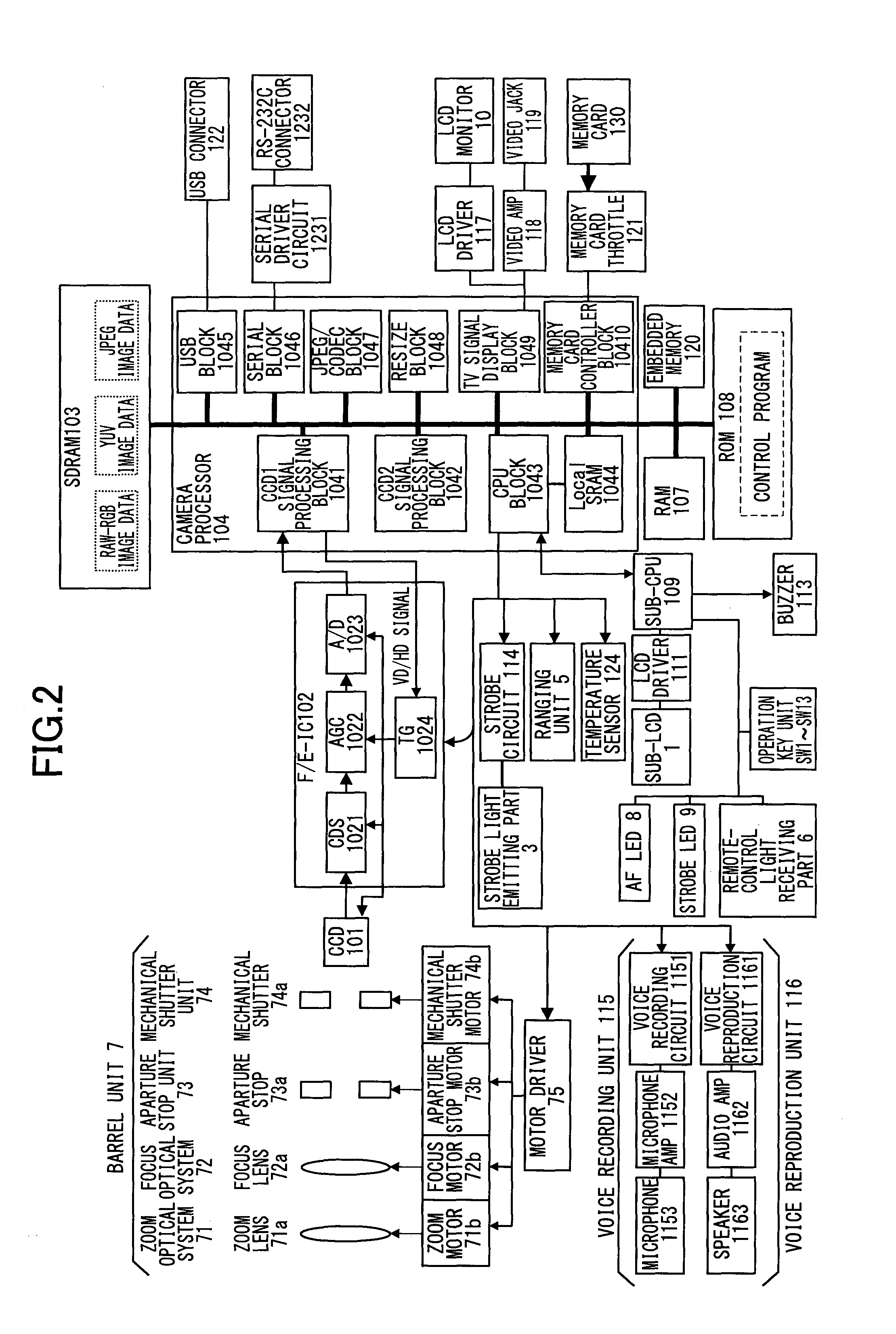

Image processor, imaging apparatus equipped with the same, and image processing method

ActiveUS20150215595A1Reduce colorSimple process configurationImage enhancementImage analysisImaging processingNoise reduction

An image processor includes a first image creator which creates first noise-processed image data by performing noise reduction processing on data on one image acquired by an imaging device, a second image creator which creates second noise-processed image data by performing noise reduction processing corresponding to a false color generated in the first noise-processed image data, and an image synthesizer which performs false color reduction by synthesizing the first noise-processed image data and the second noise-processed image data.

Owner:RICOH KK

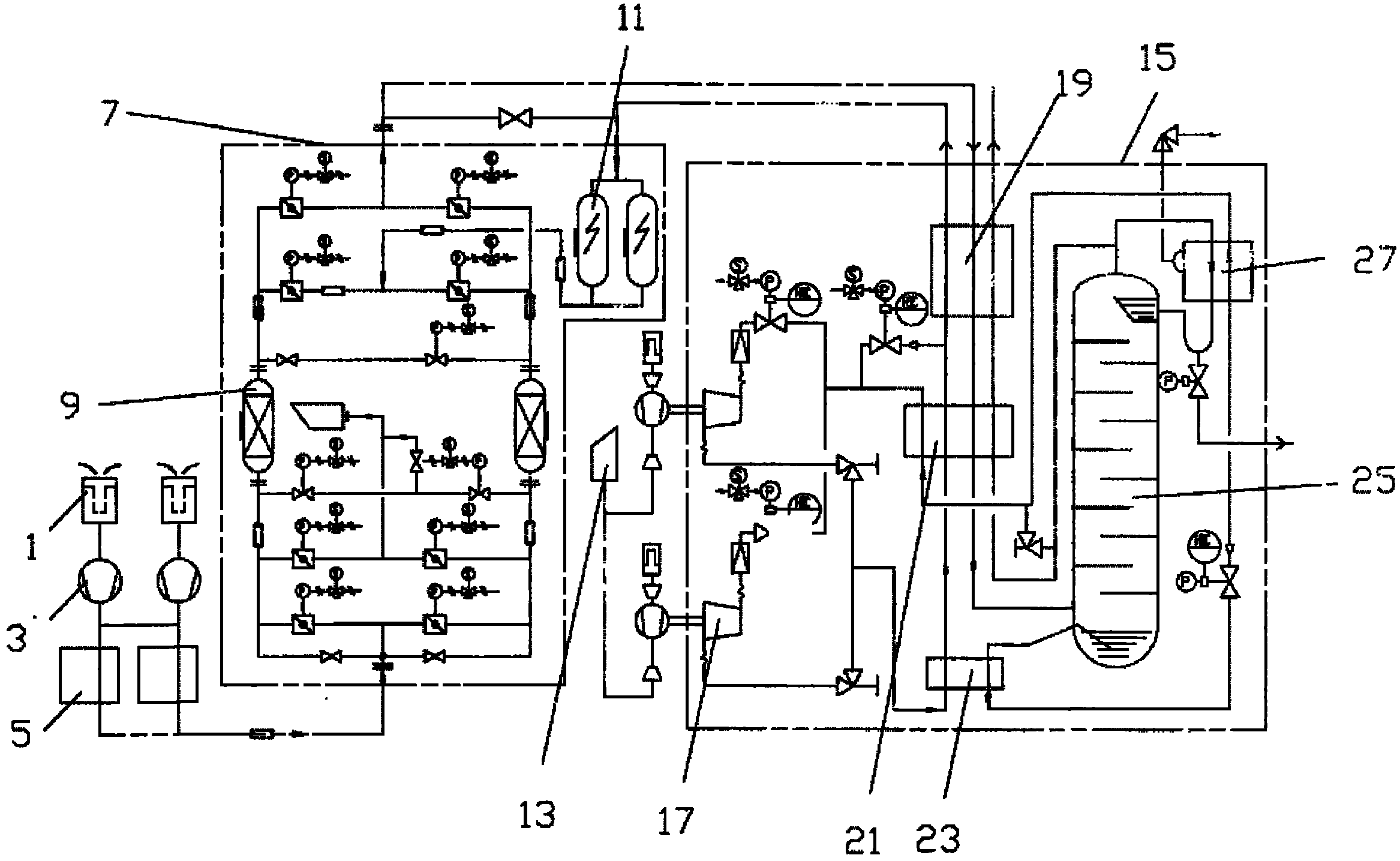

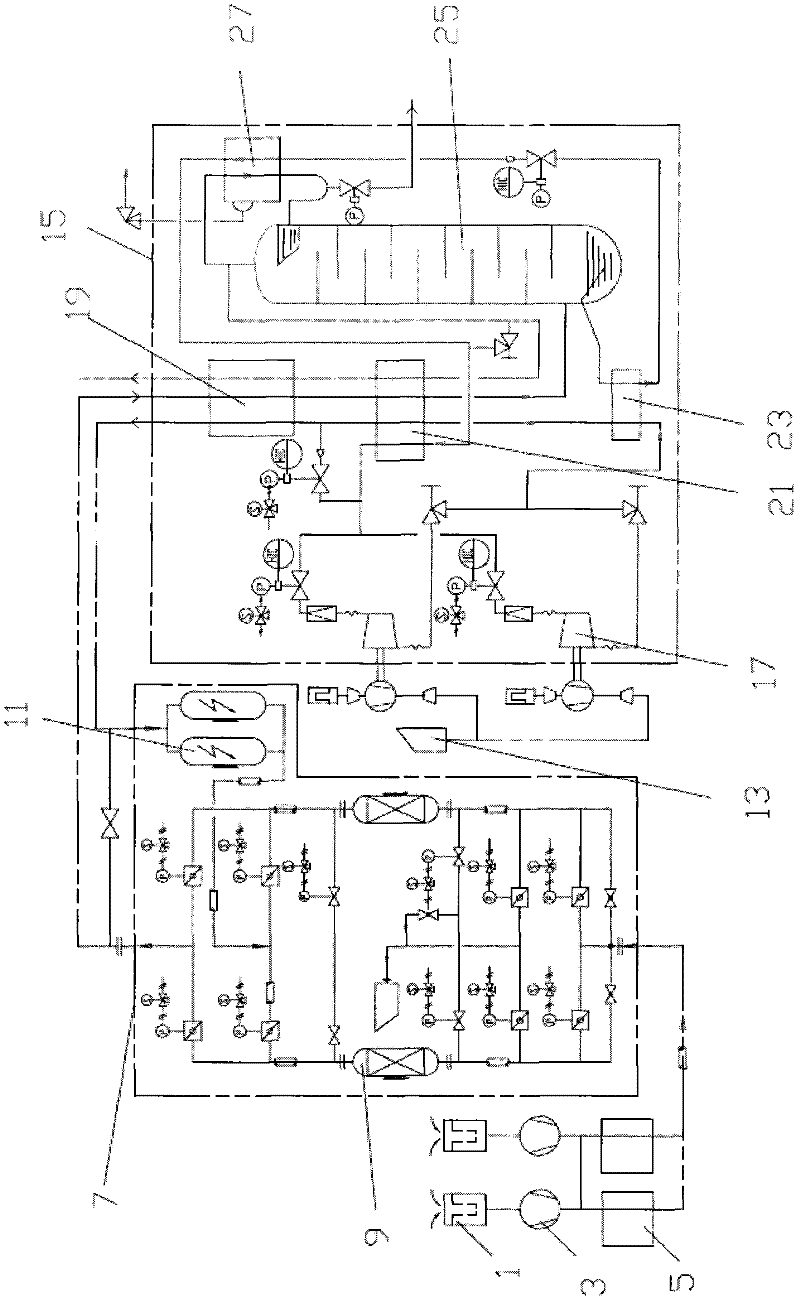

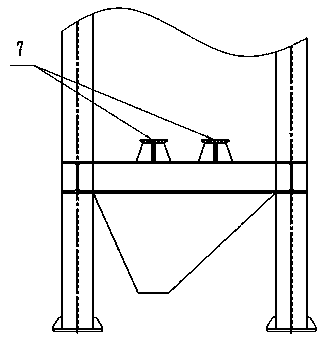

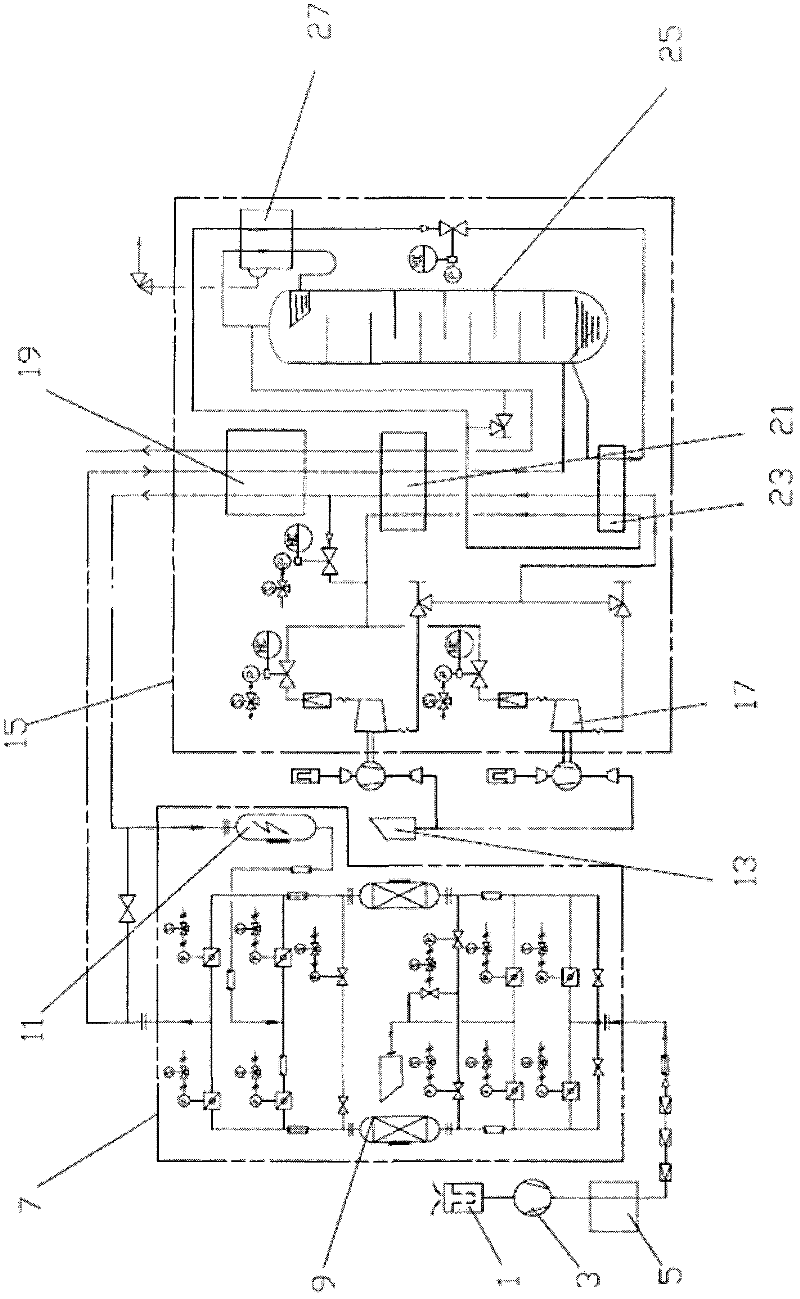

Large-tonnage high-purity nitrogen equipment

ActiveCN101929791ATake advantage ofSmall footprintSolidificationLiquefactionNitrogenProcess engineering

The invention provides large-tonnage high-purity nitrogen equipment, which comprises a preprocessing system, a purification system and a fractionating tower, wherein the preprocessing system comprises a filter, an air compressor and a cooler which are sequentially connected; the fractionating tower comprises a turbine expander, a rectifying tower and a condenser; the rectifying tower comprises an upper tower and a lower tower; the outlet of the purification system is connected to the air inlet of the lower tower through a pipeline which passes through a main heat exchanger; the lower tower is also provided with an enriched liquid air outlet; and the preprocessing system comprises two groups of filters, air compressors and coolers, which are connected in parallel and sequentially. The equipment makes full use of the cooling production of enriching oxygen and nitrogen through simultaneously connecting an enriching oxygen pipeline, a raw material air pipeline and a nitrogen pipeline to the main heat exchanger, and has the advantages of energy saving and environmental protection.

Owner:苏州制氧机股份有限公司

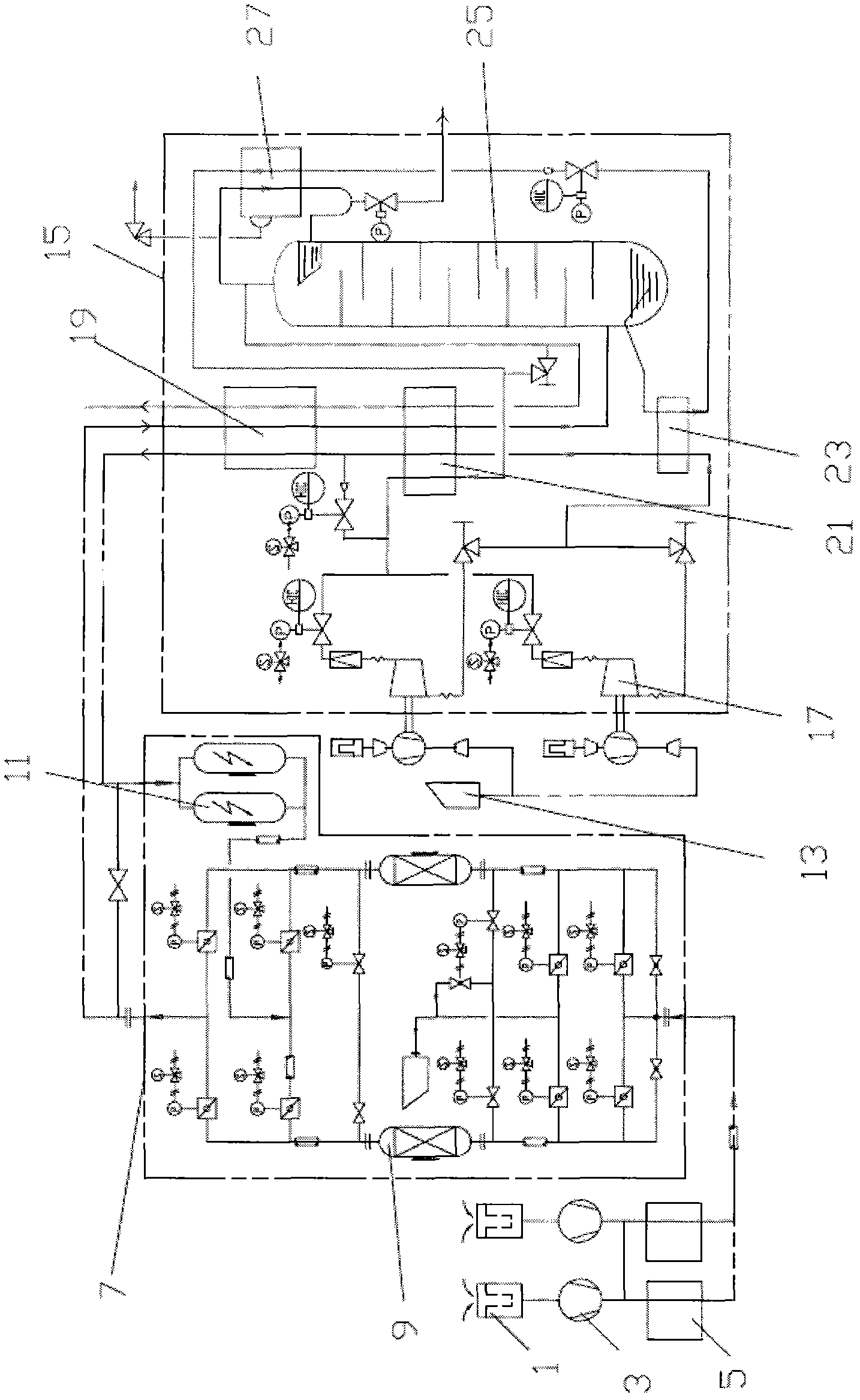

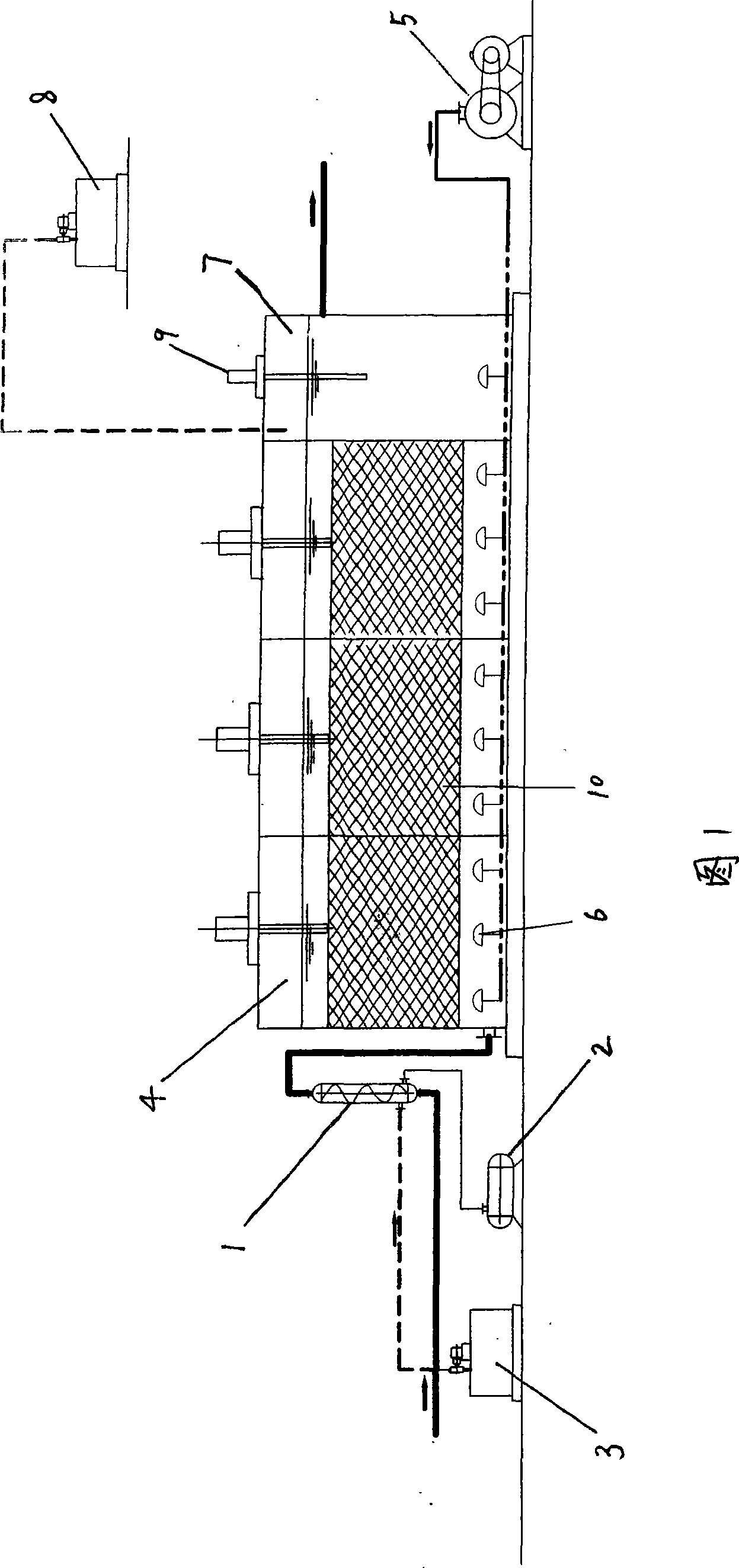

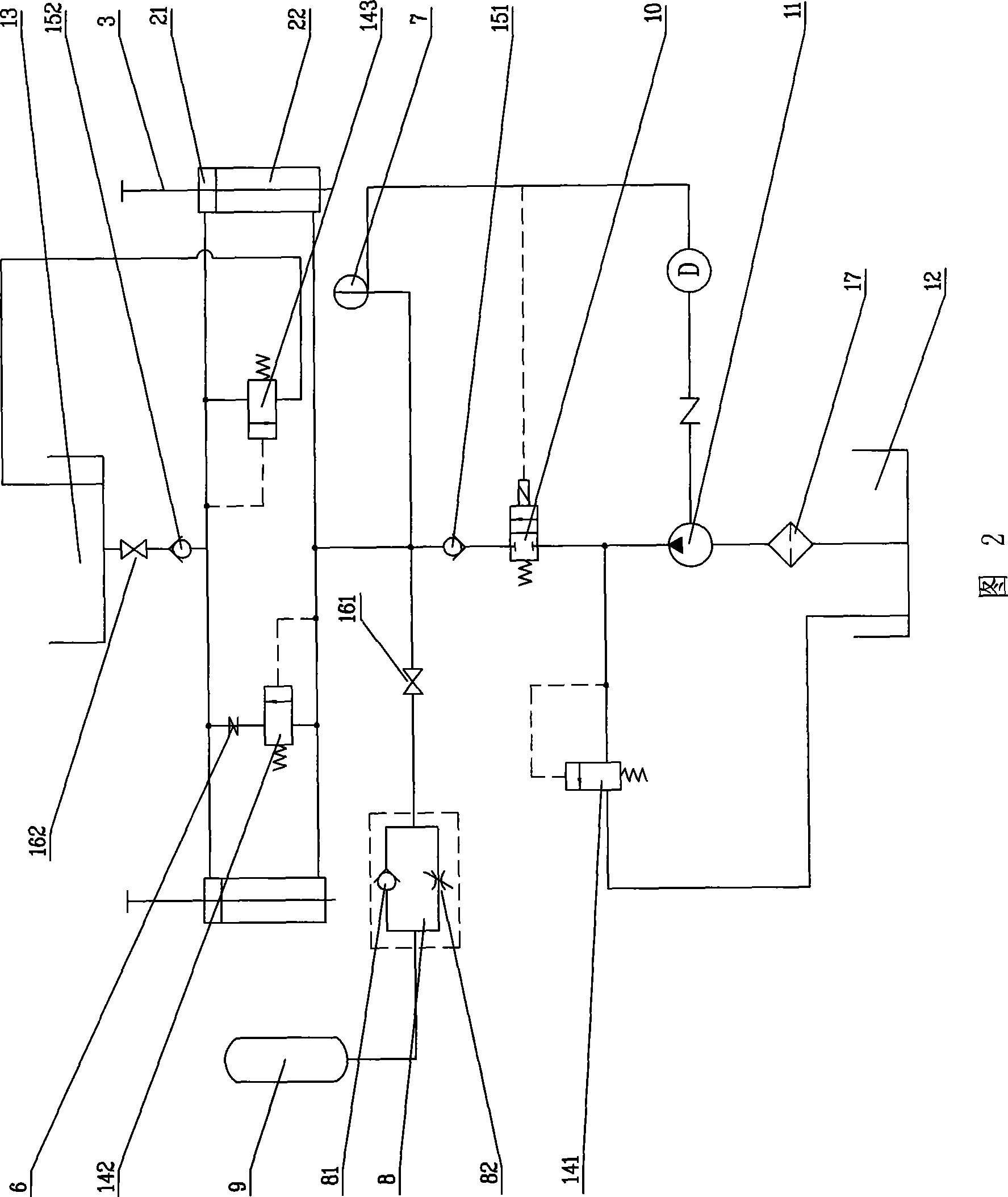

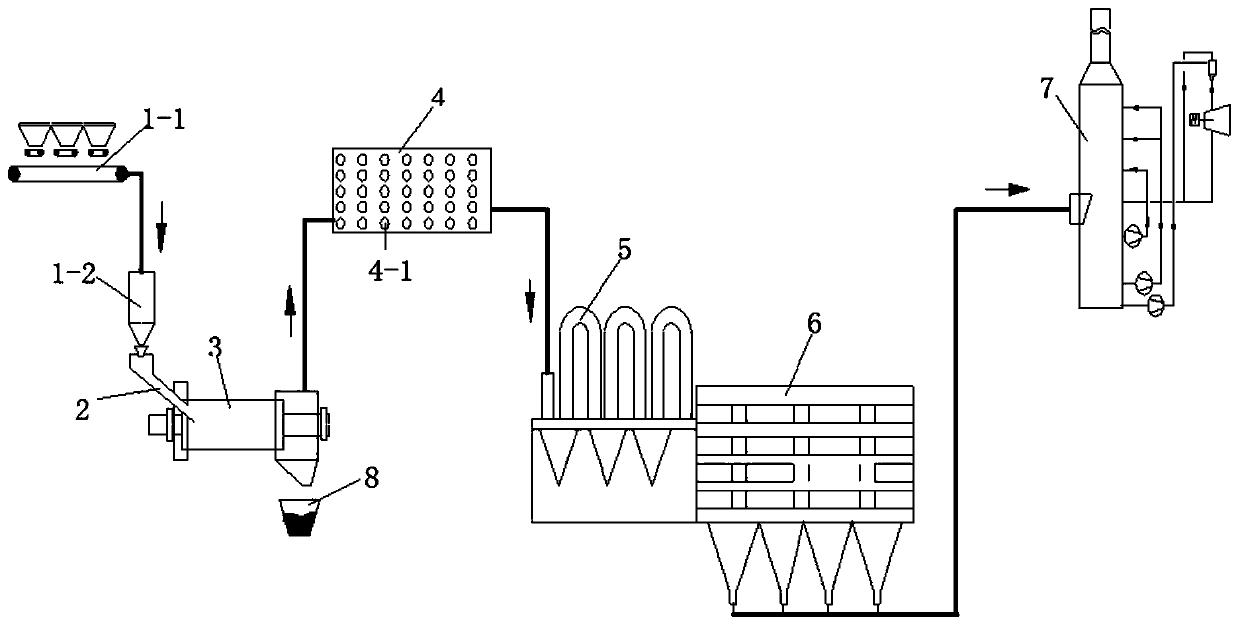

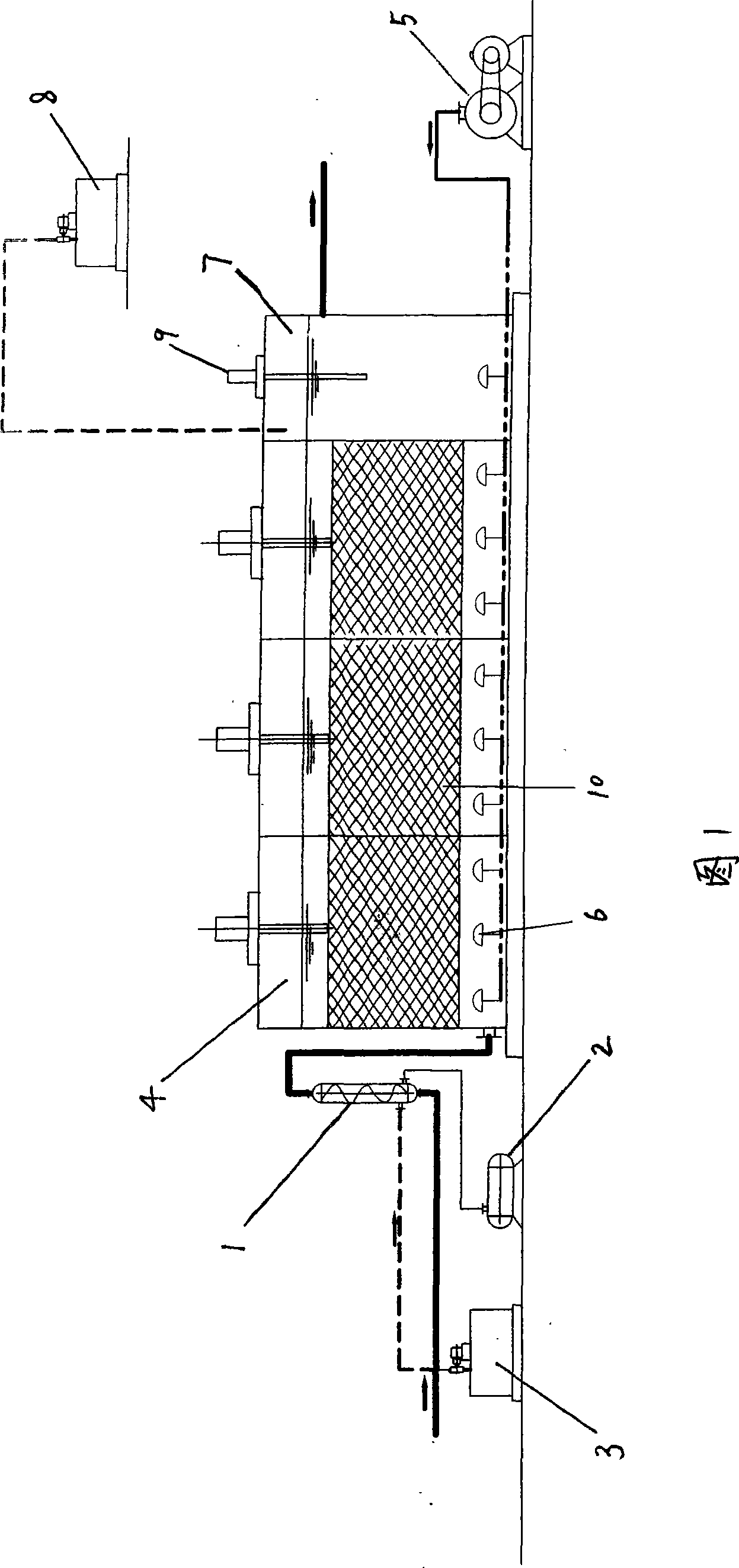

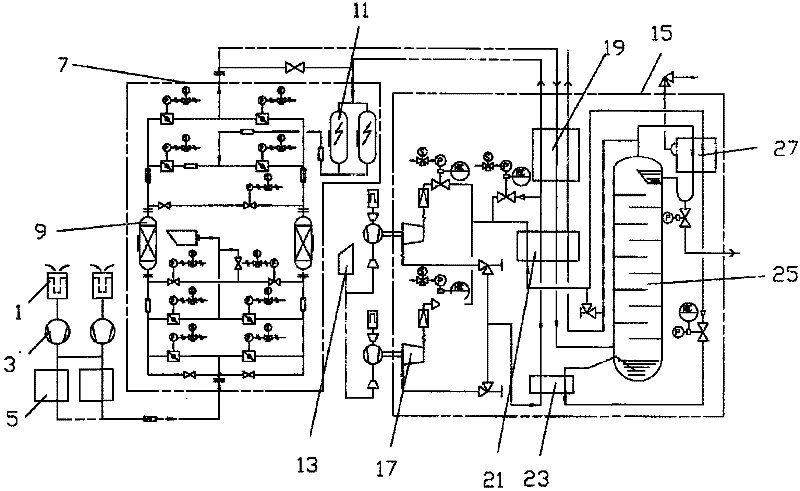

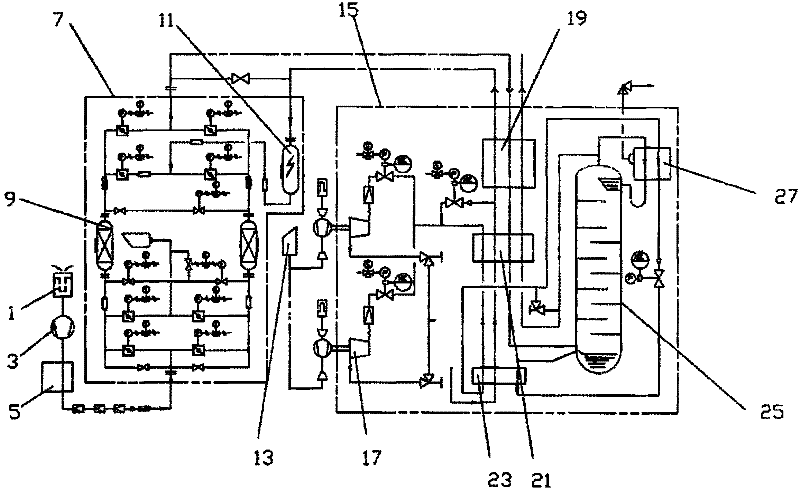

High efficiency detoxifcation method and device of organic wastewater

ActiveCN101423283AComplete setEliminate fastWater/sewage treatment by irradiationWater/sewage treatment by oxidationActivated carbonPtru catalyst

The invention relates to a high-efficiency detoxification method of organic waste water, and a device thereof. The method mainly comprises the following steps of: mixing, catalytic reaction, oxidant reduction and the like. Organic waste water to be treated is led to a pipeline mixer for sufficient mixing with H2O2 and O3, then enters a catalytic reactor composed of a catalytic reaction unit, the catalytic reaction is carried out under the action of catalysts which uses active carbons as carriers and under the inducement of ultraviolet light, and enters an oxidant reduction unit again; reducers are filled into the organic waste water, and after reduction reaction is carried out to the organic waste water, waste water which is in accordance with requirements is lead out. The device is composed of a pipeline mixer used for sufficient mixing for organic waste water, H2O2 and O3, wherein, the rear part of the pipeline mixer is connected with a catalytic reactor composed of a catalytic reaction unit; and the rear part of the catalytic reactor is connected with an oxidant reduction unit. The invention has the characteristics of simple technical allocation, low processing cost, simple operation control, good detoxification treatment effect and the like.

Owner:ZHEJIANG DONGTIANHONG ENVIRONMENTAL PROTECTION ENG CO LTD

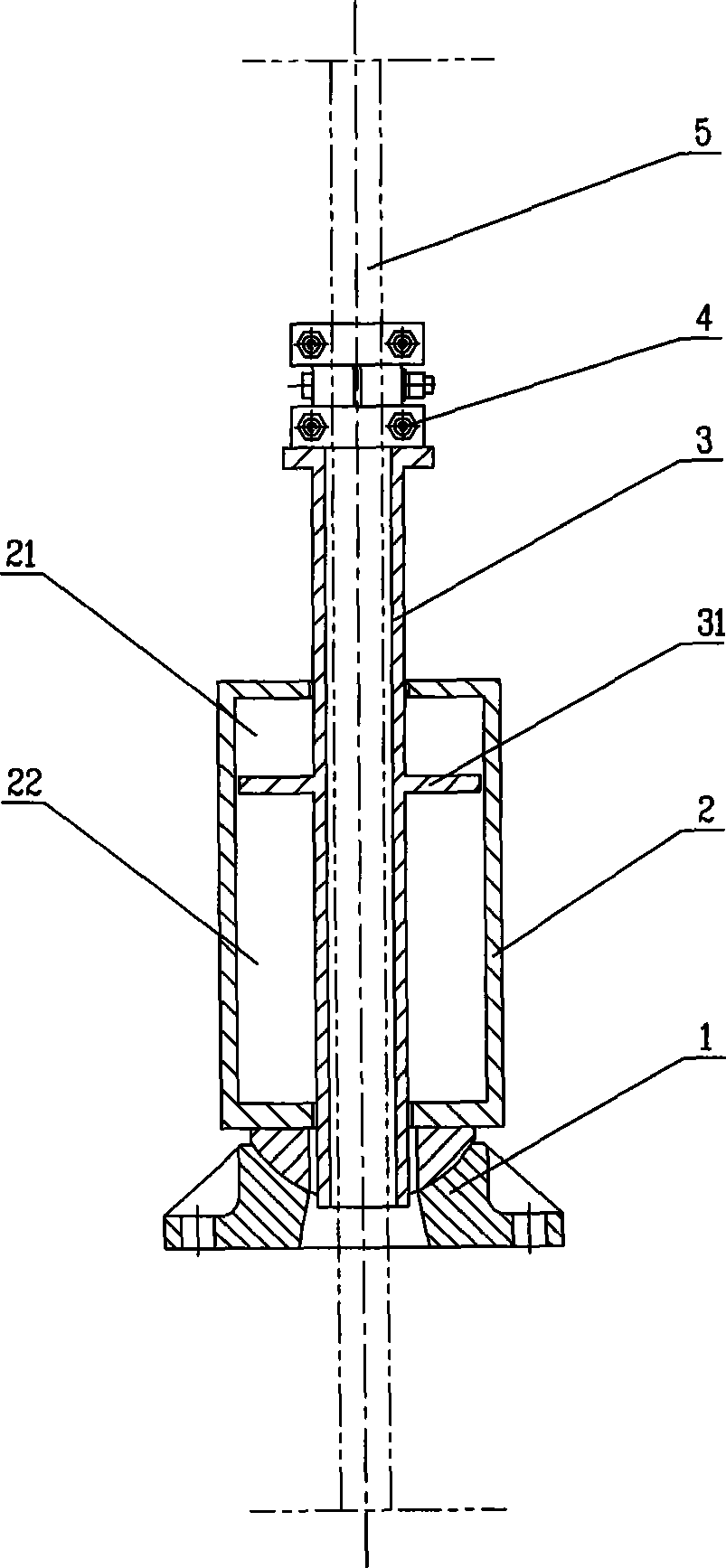

Shaft Single-rope hoisting drop-proof system

InactiveCN101422643ASolve technical problemsImprove buffering effectSafety beltsHydraulic cylinderDashpot

A vertical shaft single-rope lifting fall arrest system comprises a braking wire cable and a hydraulic dashpot which consists of a second hydraulic cylinder and a hydraulic circuit. The hydraulic cylinder is fixed on a shaft tower platform; one end of the braking wire cable is fixed on the upper end of a hollow piston rod by a rope clamp; the braking wire cable is suspended at the bottom of the shaft and tightened after passing through the hollow part of the hollow piston rod; the upper cavity and the lower cavity of the second hydraulic cylinder are communicated; with the function of the hydraulic circuit, instant massive attack can be effectively buffered and when hydraulic liquid passes, great energy consumption is produced so that attack towards the system can be reduced and the kinetic energy of falling containers can be consumed away so as to have the buffer function and protect the personnel safety.

Owner:CINF ENG CO LTD

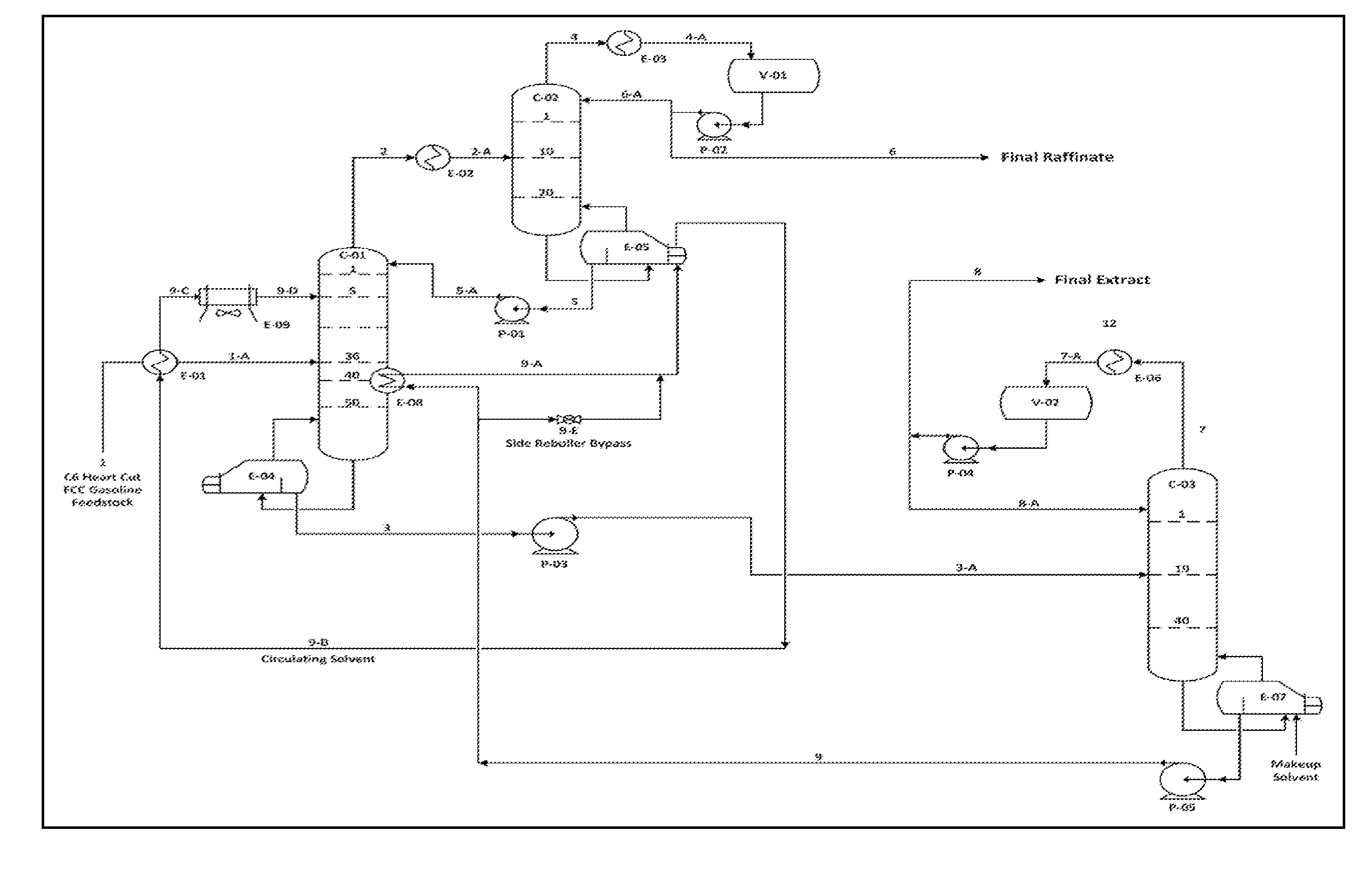

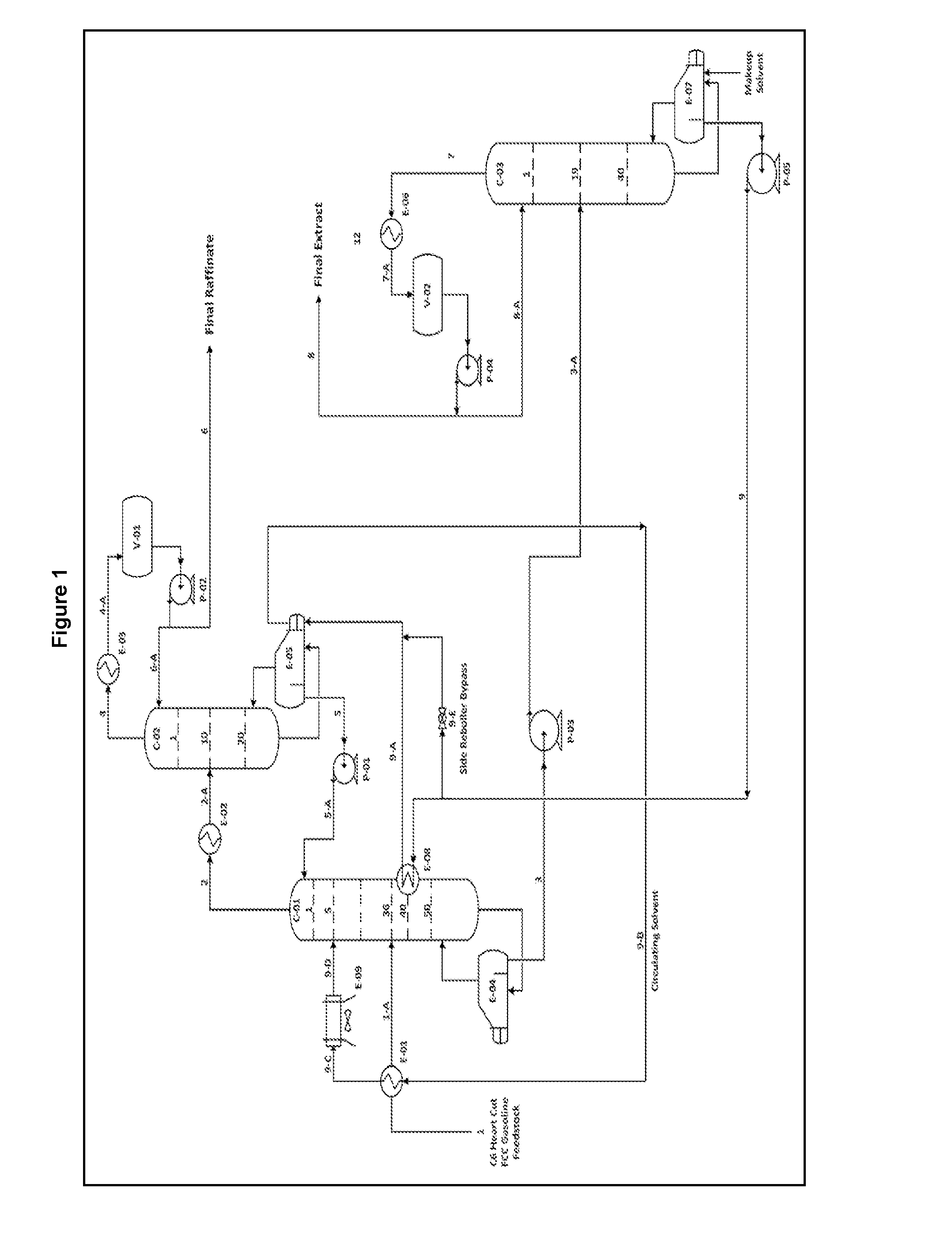

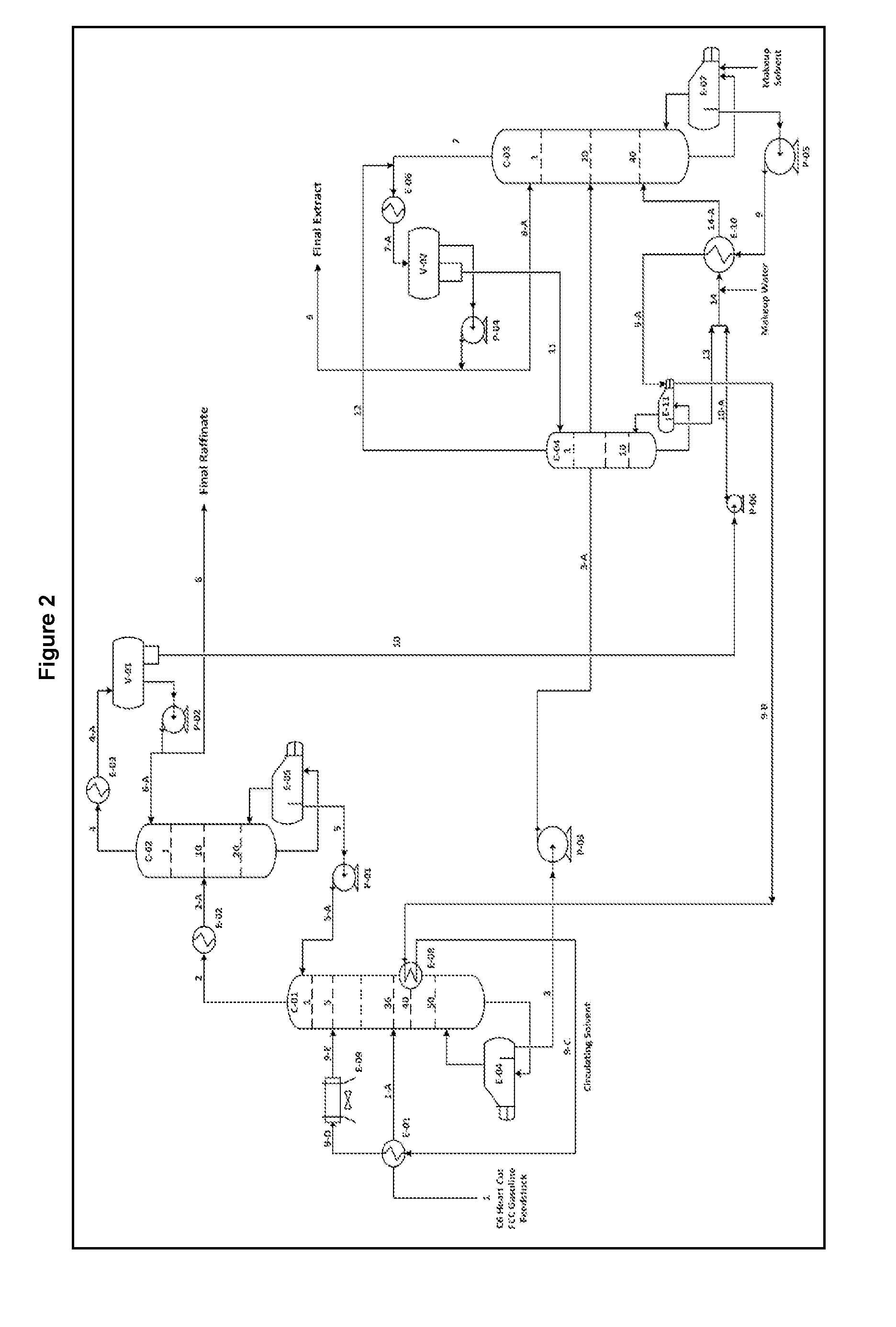

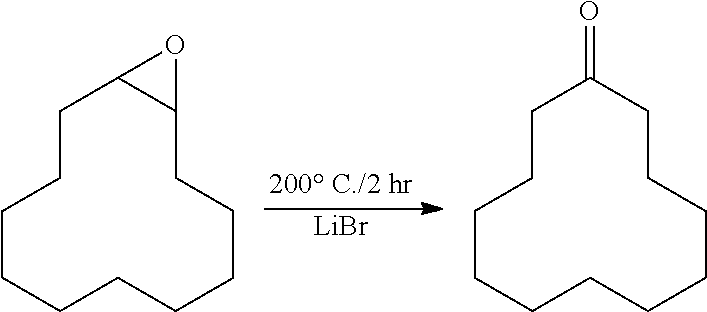

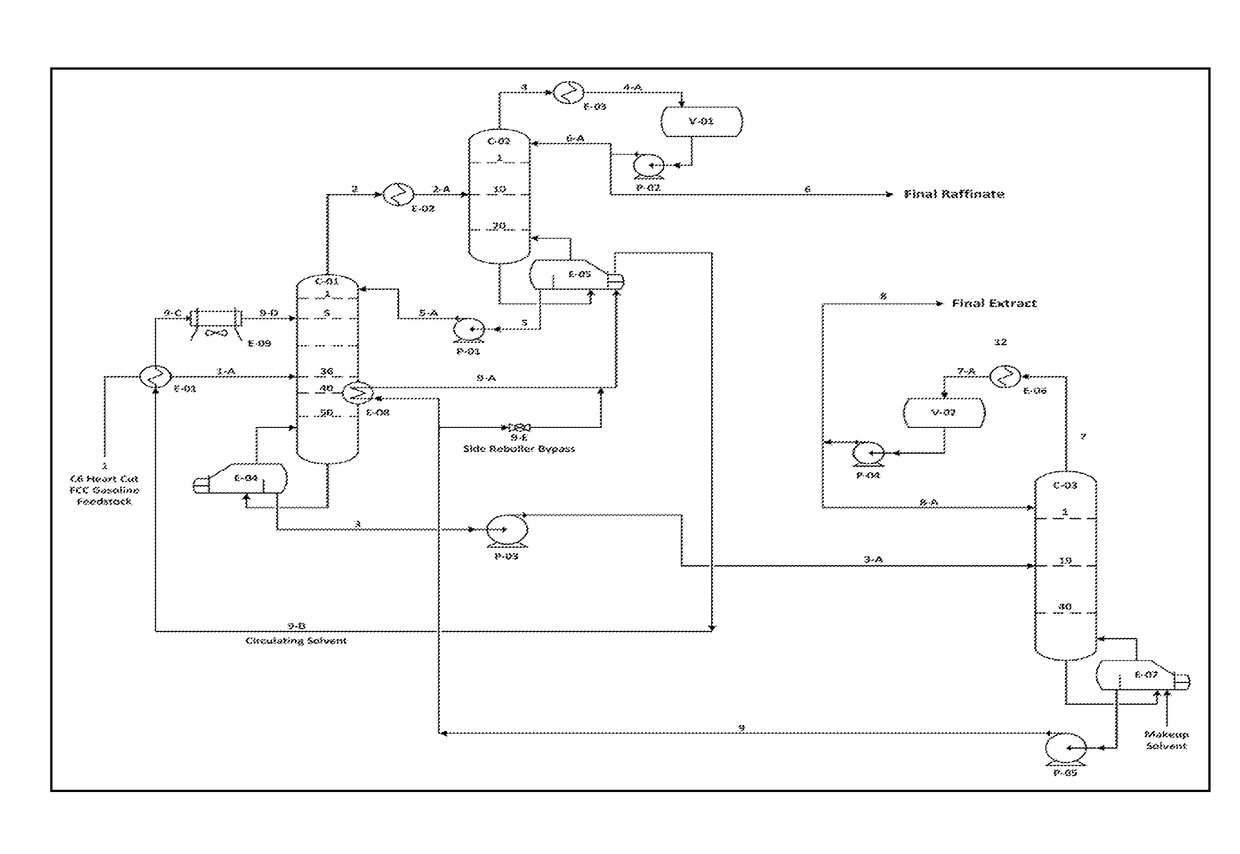

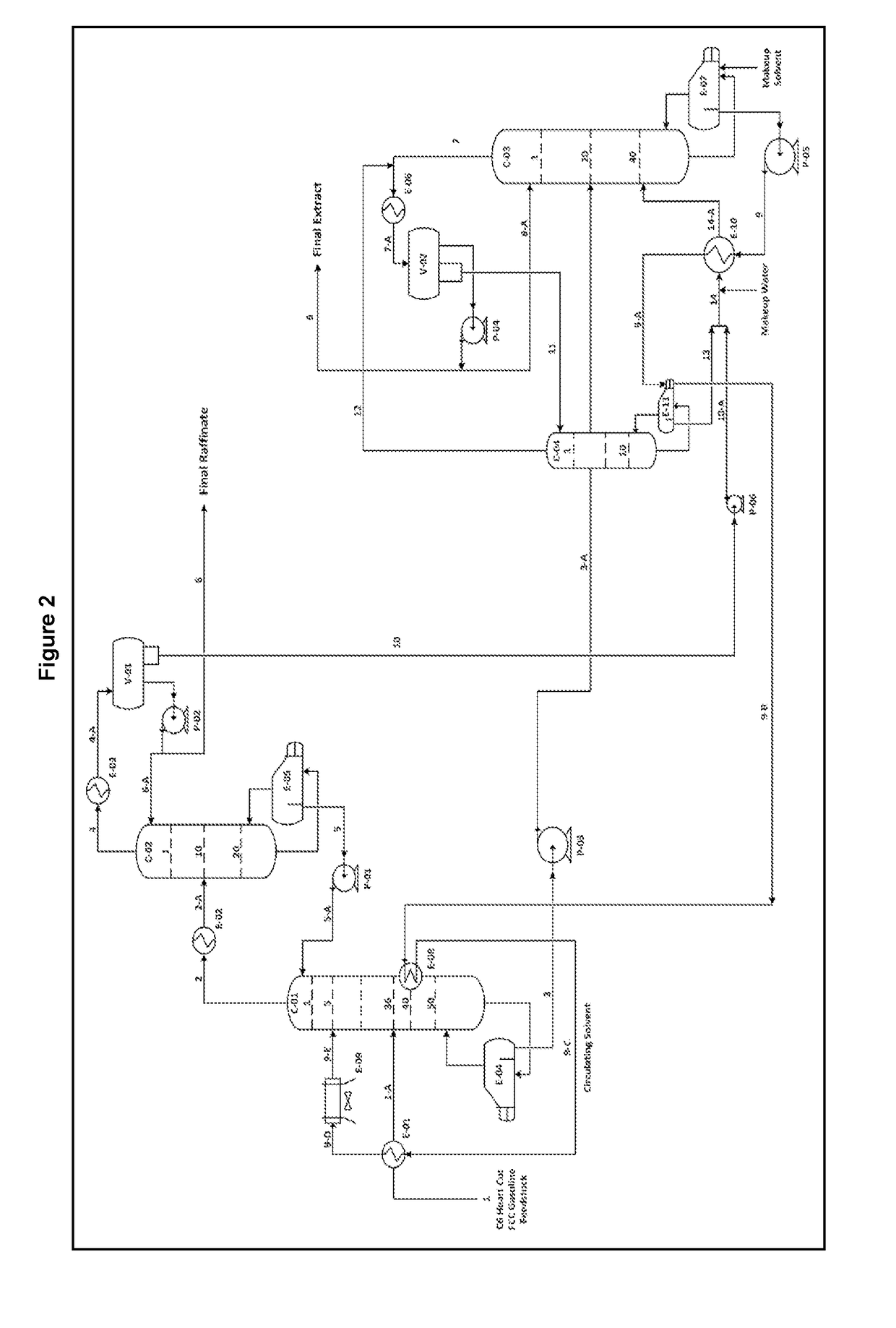

Process for simultaneous production of benzene lean gasoline and high purity benzene from cracked gasoline fraction

ActiveUS20160288014A1Improve production yieldHigh purityTreatment with plural serial stages onlyDistillation purification/separationCyclic alkaneBenzene

Disclosed is a process for simultaneous production of benzene lean gasoline and recovery of high purity aromatics from narrow boiling light cracked gasoline fractions. The present invention provides a vacuum based two stage extractive distillation process, with pure NMP, for production of benzene lean gasoline (benzene content less than 0.4 Weight %) by recovery of high purity aromatics (purity more than 99 Weight %) from cracked gasoline fractions (boiling in the range of 40-90° C.) comprising benzene in the range of 10-30 weight % and close-boiling non-aromatic hydrocarbons like paraffins, iso-paraffins, olefins, di-olefins (including conjugated di-olefins), and naphthenes in the range of 70-90 weight % along with impurities containing but not limited to oxygenates, metals, chlorides, sulphur compounds, nitrogen compounds and organic peroxides.The present invention provides an improved extractive distillation process for simultaneous production of benzene lean gasoline and benzene rich product from cracked gasoline fraction, with higher recovery of better quality products along with lower utility requirements and investment costs.

Owner:COUNCIL OF SCI & IND RES

Integrated gas/liquid separating device with automatically controlled liquid level

InactiveCN1242826CSimple structureSmall footprintLiquid degasificationVapor–liquid separatorIntegrated design

Owner:CHINA PETROLEUM & CHEM CORP +1

System and process for treating low-grade tin raw material by reducing roasting

The invention discloses a system and process for treating low-grade tin raw materials by reducing roasting. The system for treating low-grade tin raw materials by reducing roasting is characterized inthat low-grade tin raw materials with the tin mass content of 1%-15% are mixed into a reducing agent through a batching system, the low-grade tin raw materials are fed into a rotary kiln for weak reduction roasting, so that SnO2 in the low-grade tin raw materials is converted into volatile SnO to volatilize into a secondary combustion chamber, the SnO is oxidized into the SnO2 in the secondary combustion chamber, and then is cooled by a flue gas cooling system, then a SnO2 product with the tin content of more than 35% is collected in a cloth bag dust collector, tail gas discharged from the cloth bag dust collector is treated by a sulfur dioxide recovery system, and is discharged after reaching the standard; the content of tin contained in furnace slag produced by the rotary kiln is reduced to 0.2% or below, and the furnace slag is fed into a slag bucket. The system and process is energy-saving and environment-friendly, the recovery rate of the tin metal is high, and the comprehensiveutilization effect of resources is good.

Owner:YUNNAN TIN

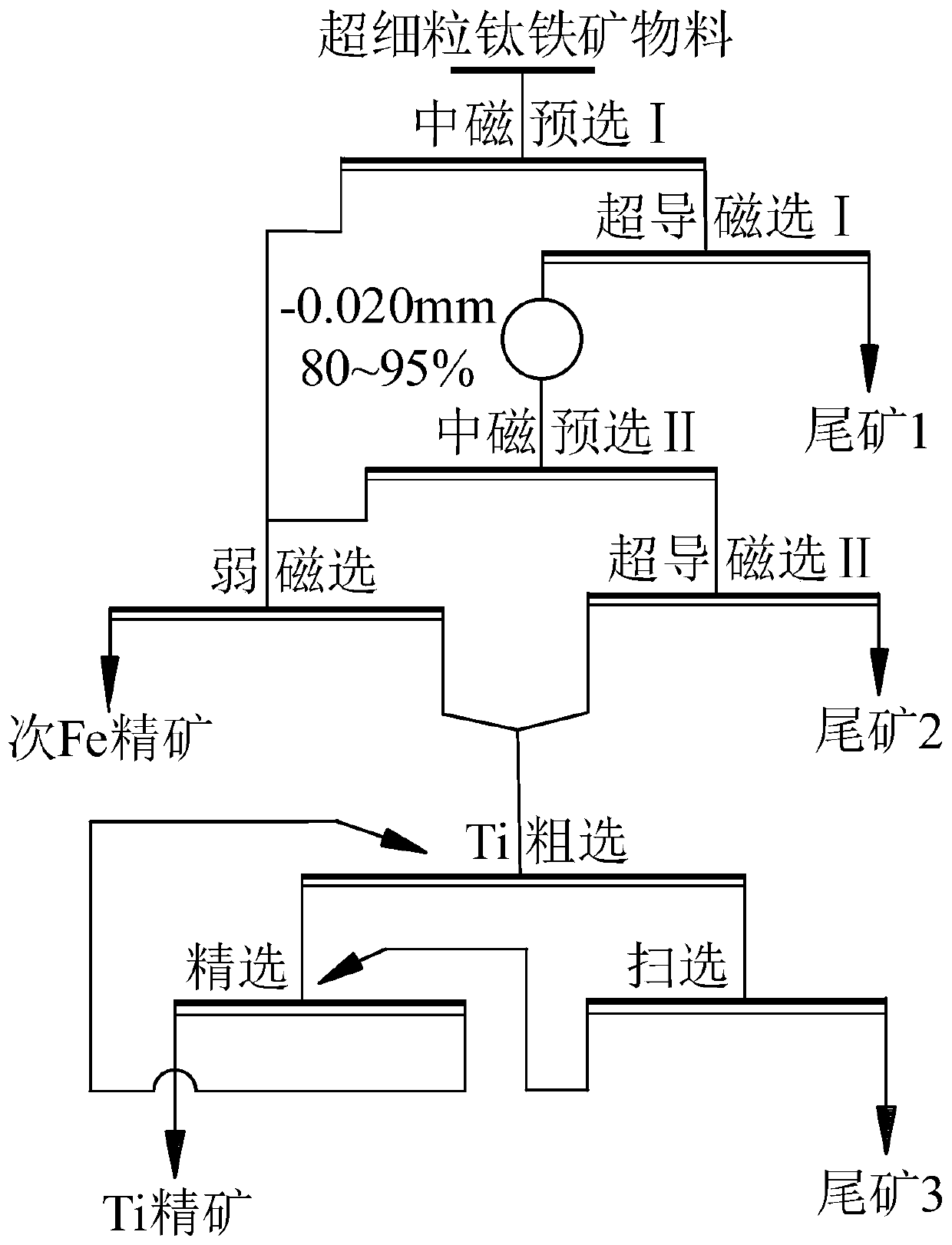

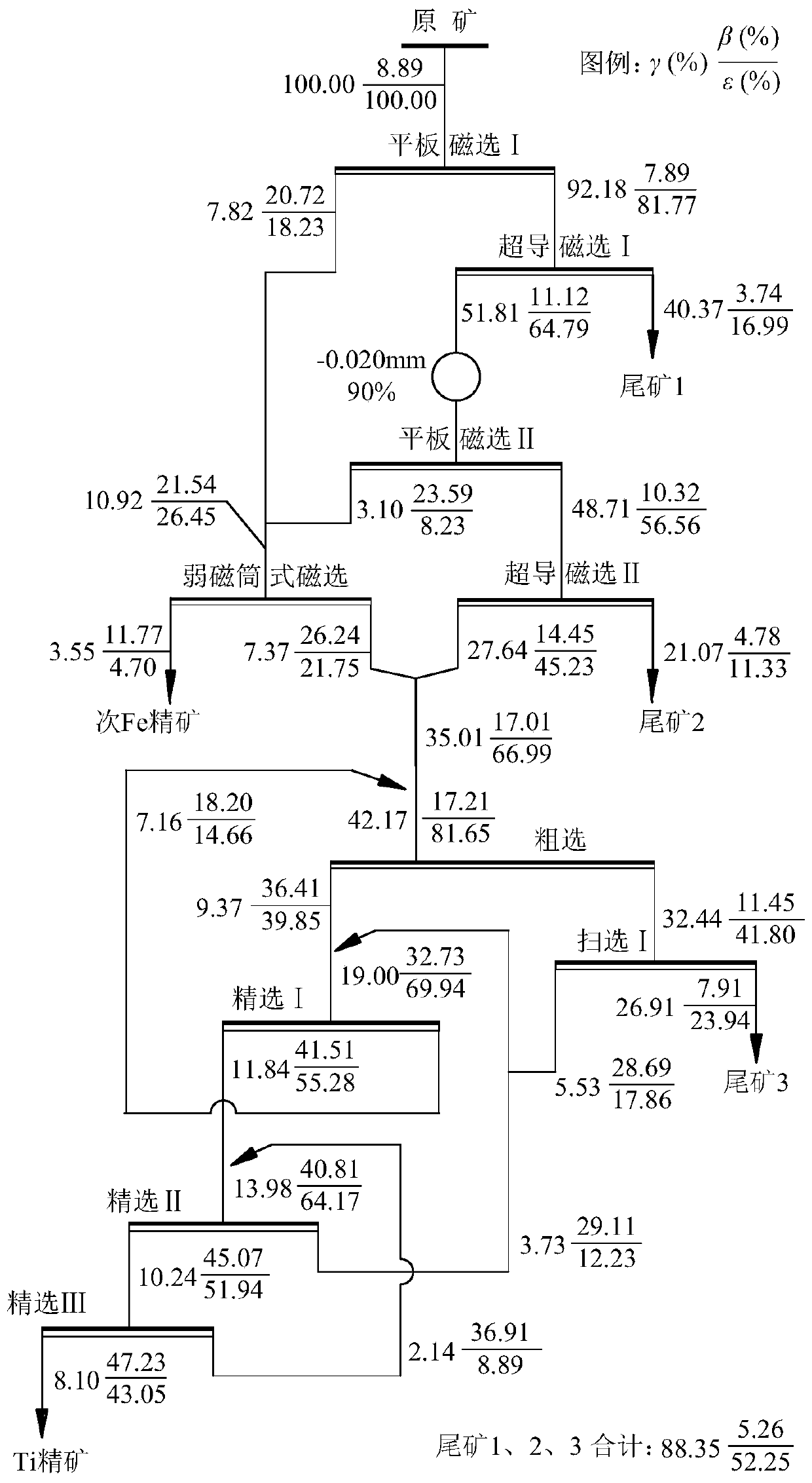

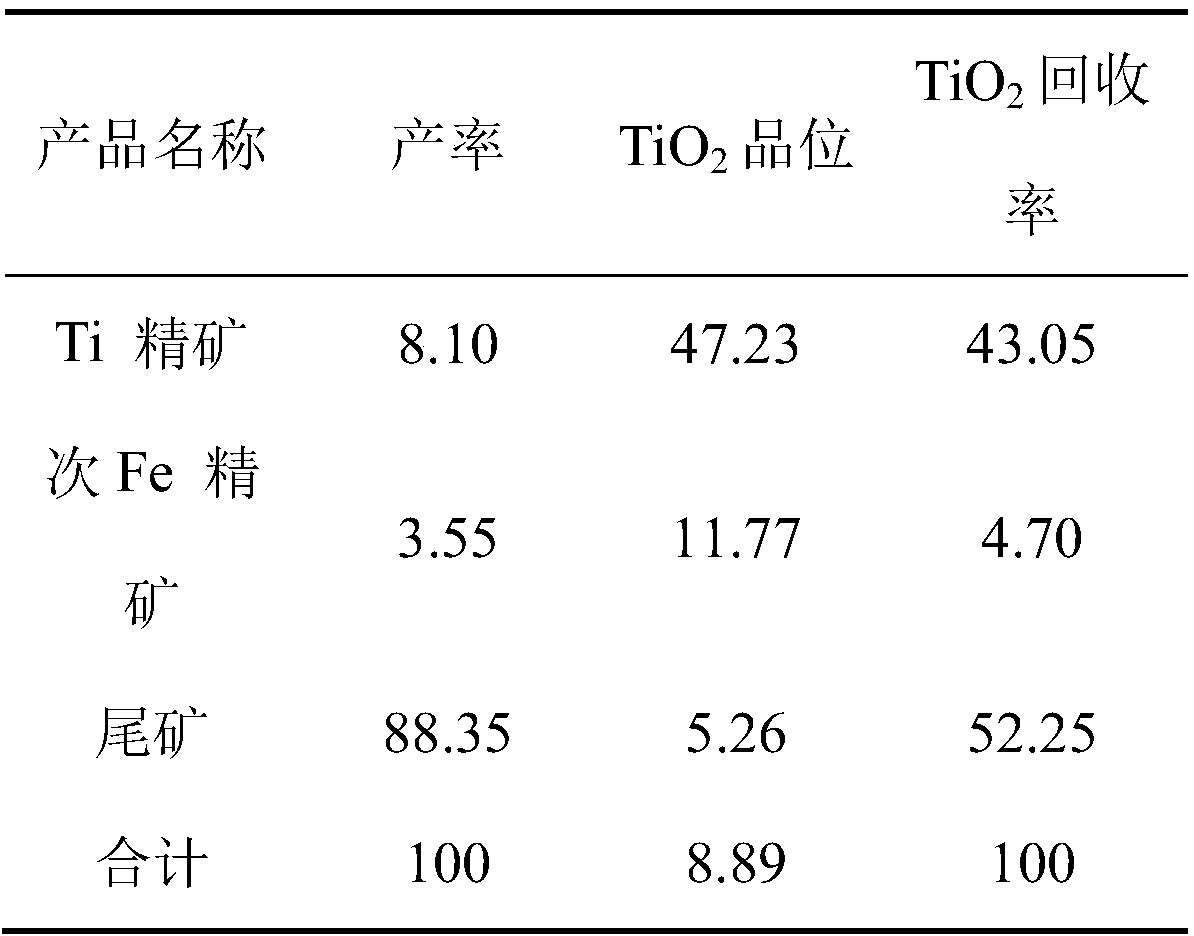

Ultrafine-grained ilmenite material pre-enrichment and selection process

InactiveCN110665640AEfficient removalHigh efficiency pre-enrichmentFlotationMagnetic separationIlmeniteEnergy consumption

The invention discloses an ultrafine-grained ilmenite material pre-enrichment and selection process. The process mainly comprises the following two parts of (1) realizing effective pre-enrichment of ultrafine-grained ilmenite by using a ''medium magnetic pre-selection-superconducting magnetic separation'' process to obtain a flotation raw material; and (2) using a ''flotation machine-flotation column'' combined process to select ilmenite after magnetic separation pre-enrichment, and finally acquiring ilmenite concentrate whose TiO2 grade is greater than 47% and a TiO2 recovery rate is greaterthan 40%. The method of the invention has the characteristics of low energy consumption, high efficiency, easy conversion into production practice and the like, and effective recovery of ultrafine-grained ilmenite is realized under a condition of ensuring quality of concentrate products.

Owner:江苏旌凯中科超导高技术有限公司

High efficiency detoxifcation method and device of organic wastewater

ActiveCN101423283BComplete setEliminate fastWater/sewage treatment by irradiationWater/sewage treatment by oxidationActivated carbonPtru catalyst

The invention relates to a high-efficiency detoxification method of organic waste water, and a device thereof. The method mainly comprises the following steps of: mixing, catalytic reaction, oxidant reduction and the like. Organic waste water to be treated is led to a pipeline mixer for sufficient mixing with H2O2 and O3, then enters a catalytic reactor composed of a catalytic reaction unit, the catalytic reaction is carried out under the action of catalysts which uses active carbons as carriers and under the inducement of ultraviolet light, and enters an oxidant reduction unit again; reducers are filled into the organic waste water, and after reduction reaction is carried out to the organic waste water, waste water which is in accordance with requirements is lead out. The device is composed of a pipeline mixer used for sufficient mixing for organic waste water, H2O2 and O3, wherein, the rear part of the pipeline mixer is connected with a catalytic reactor composed of a catalytic reaction unit; and the rear part of the catalytic reactor is connected with an oxidant reduction unit. The invention has the characteristics of simple technical allocation, low processing cost, simple operation control, good detoxification treatment effect and the like.

Owner:ZHEJIANG DONGTIANHONG ENVIRONMENTAL PROTECTION ENG CO LTD

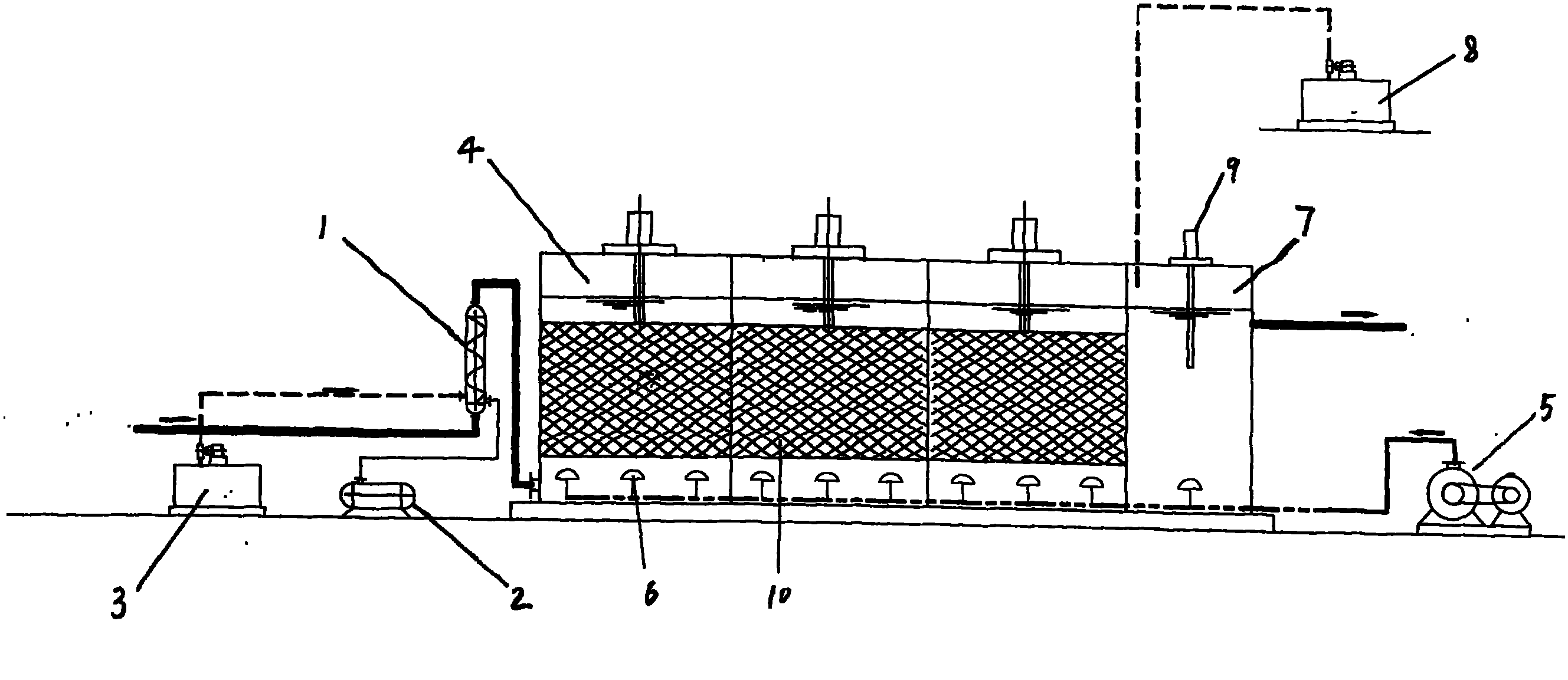

System and method for producing vanadium pentoxide

The invention relates to a system and a method for producing vanadium pentoxide. The system is characterized in that a stirring container is arranged below a first feed bin; an upper part of the stirring container is communicated with a lime milk container by a pipe; the stirring container is communicated with a first filter press by a pipe; a first electric box furnace is arranged below the first filter press; a second feed bin is arranged below the first electric box furnace; an alkali liquor container is arranged below the second feed bin; a second filter press is arranged below the alkali liquor container; a collection tank is arranged below the second filter press; a third filter press is arranged below the collection tank; a work bin is arranged below the third filter press; a second electric box furnace is arranged below the work bin; the top of the collection tank is communicated with a sulfuric acid container by a pipe; and the top of the alkali liquor container is communicated with an alkali bin by a pipe. The method is simple. The system adopts the reasonable devices and is convenient for maintenance.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Large-tonnage high-purity nitrogen equipment

ActiveCN101929791BTake advantage ofSmall footprintSolidificationLiquefactionNitrogenProcess engineering

The invention provides large-tonnage high-purity nitrogen equipment, which comprises a preprocessing system, a purification system and a fractionating tower, wherein the preprocessing system comprises a filter, an air compressor and a cooler which are sequentially connected; the fractionating tower comprises a turbine expander, a rectifying tower and a condenser; the rectifying tower comprises anupper tower and a lower tower; the outlet of the purification system is connected to the air inlet of the lower tower through a pipeline which passes through a main heat exchanger; the lower tower isalso provided with an enriched liquid air outlet; and the preprocessing system comprises two groups of filters, air compressors and coolers, which are connected in parallel and sequentially. The equipment makes full use of the cooling production of enriching oxygen and nitrogen through simultaneously connecting an enriching oxygen pipeline, a raw material air pipeline and a nitrogen pipeline to the main heat exchanger, and has the advantages of energy saving and environmental protection.

Owner:苏州制氧机股份有限公司

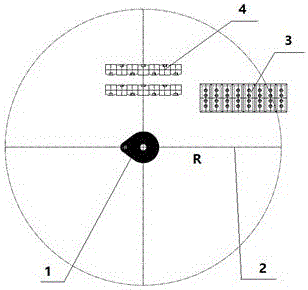

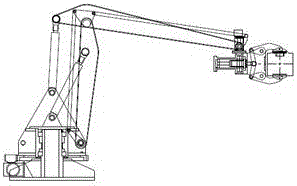

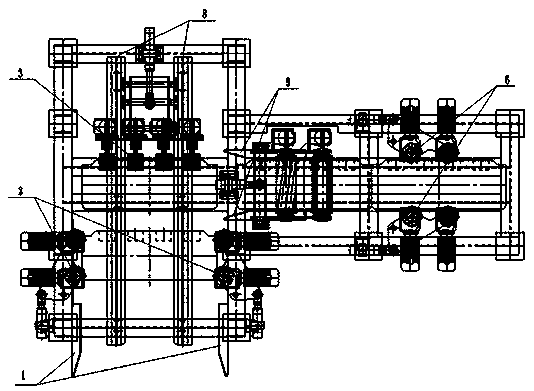

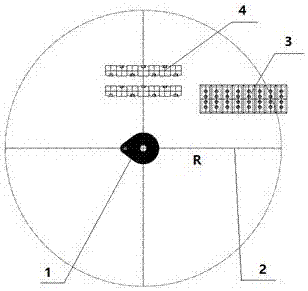

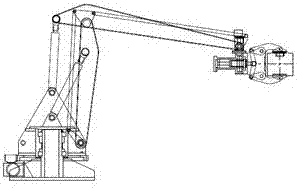

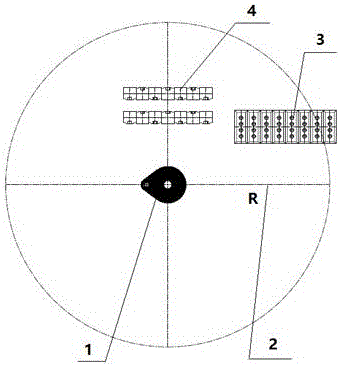

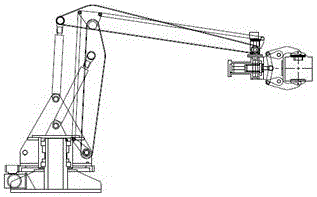

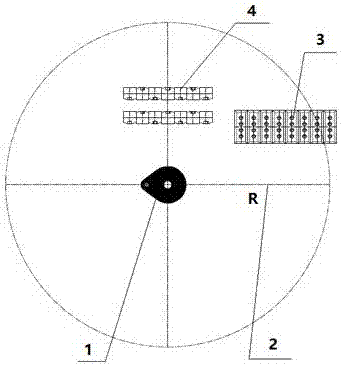

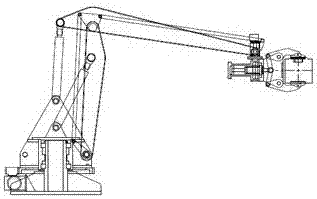

Method for disassembling wrought anode carbon blocks by using mechanical arm

ActiveCN106044186ASimple process configurationReduce investmentConveyor partsProduction lineManipulator

The invention a method for disassembling wrought anode carbon blocks by using a mechanical arm. Equipment used in the method comprises a mechanical arm, a wrought anode carbon block conveying line, a disassembled carbon block storage basket and wrought anode carbon blocks. One end of the wrought anode carbon block conveying line and the disassembled carbon block storage basket are located in a working radius R of the mechanical arm; the wrought anode carbon block conveying line is used for stacking the wrought anode carbon blocks disassembled and clamped by the mechanical arm from the disassembled carbon block storage basket and conveying the wrought anode carbon blocks to a carbon block warehouse; the disassembled carbon block storage basket is used for storing the wrought anode carbon blocks clamped by a special clamp of a multifunctional roasting unit. Through the adoption of the method, the mechanical arm is used for disassembling the wrought anode carbon blocks; the method has the characteristics of simple structure, safety, reliability and convenience in use of the equipment; through the adoption of an automatic production line manner, a large quantity of manpower is reduced during operation; the capital investment is reduced; the cost of the enterprise is reduced; the production efficiency is improved; the requirements of practical production can be met; the method is suitable for large-scale popularization and application.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

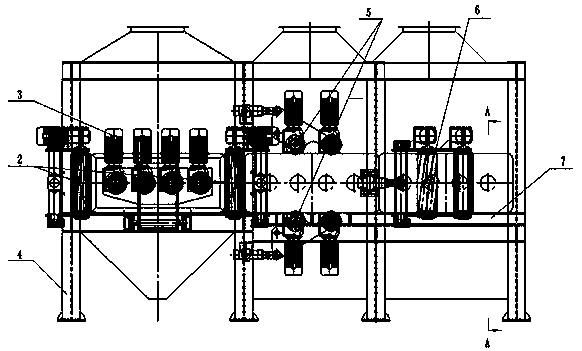

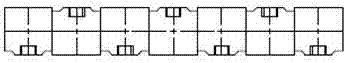

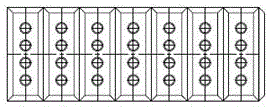

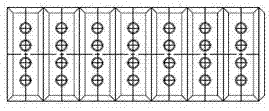

A kind of carbon block cleaning equipment

The invention discloses a new type of carbon block cleaning equipment, which includes a frame, a cleaning device, a support rail, a guide rail, and a driving device. The support rail and the guide rail are arranged on the frame, and the cleaning device is located on the support rail. It is driven to realize its swing, and the carbon blocks are cleaned during the swing process. The support track includes a support track 1 and a support track 2, and the guide track includes a guide track 1 and a guide track 2 corresponding to the support track. The cleaning equipment of the present invention can clean the adhered coke particles and coke powder on the six surfaces of the roasted anode carbon block and the inner surface of the carbon bowl hole group. Therefore, the equipment has a simple structure, is safe, reliable and easy to use. specialty. At the same time, it also simplifies the process configuration, adopts automated cleaning methods, reduces labor costs, saves capital investment, reduces costs for enterprises, improves production efficiency, meets actual production needs, and is suitable for large-scale promotion and application.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

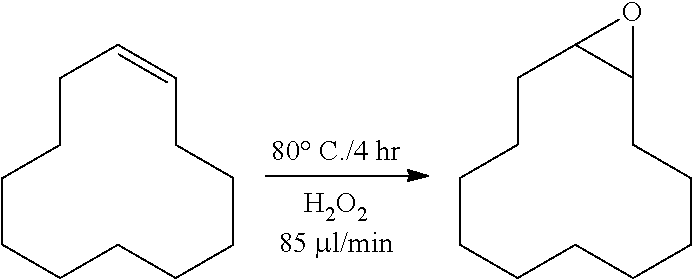

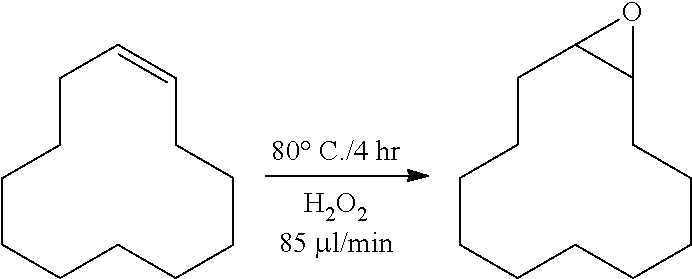

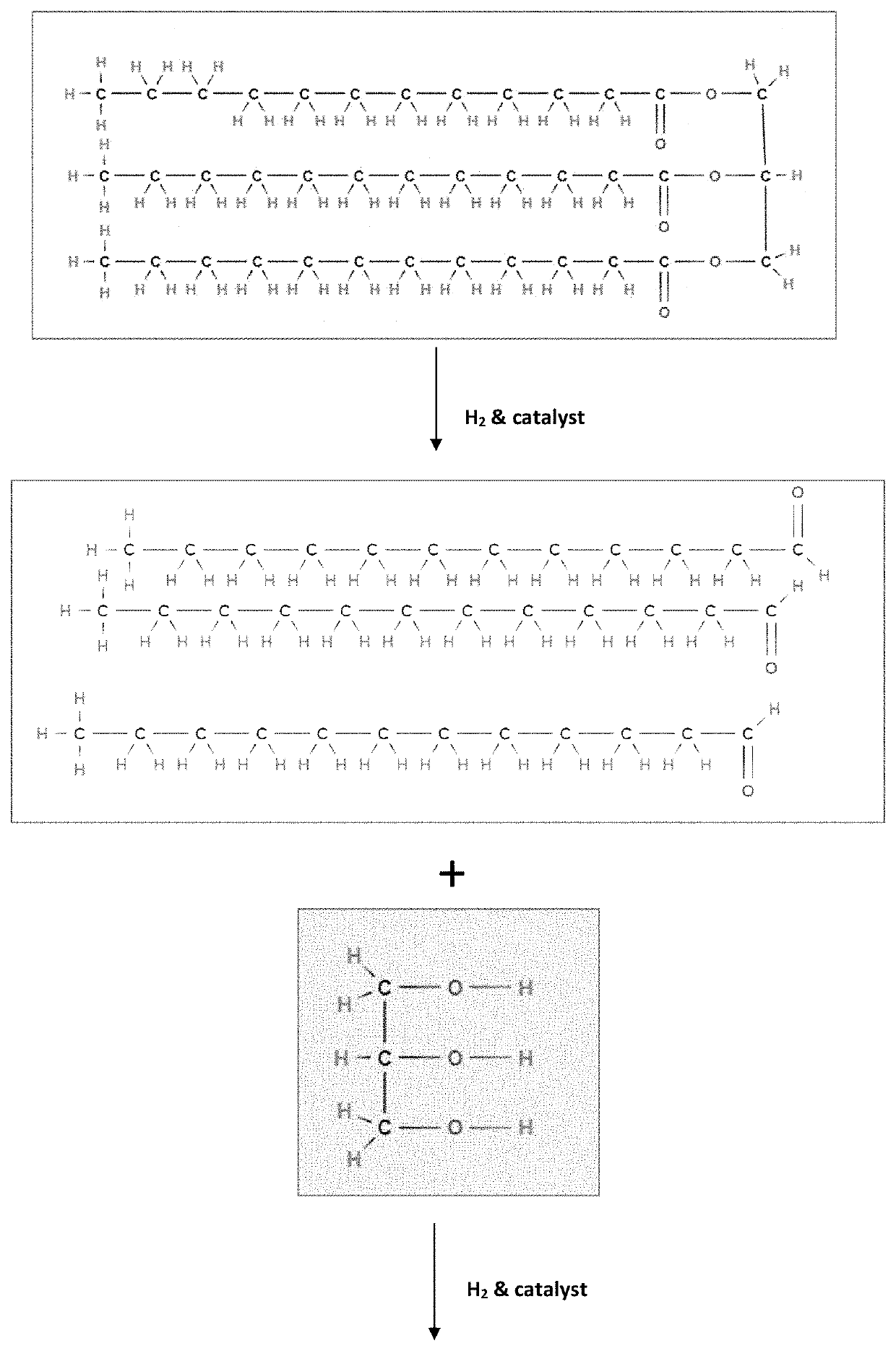

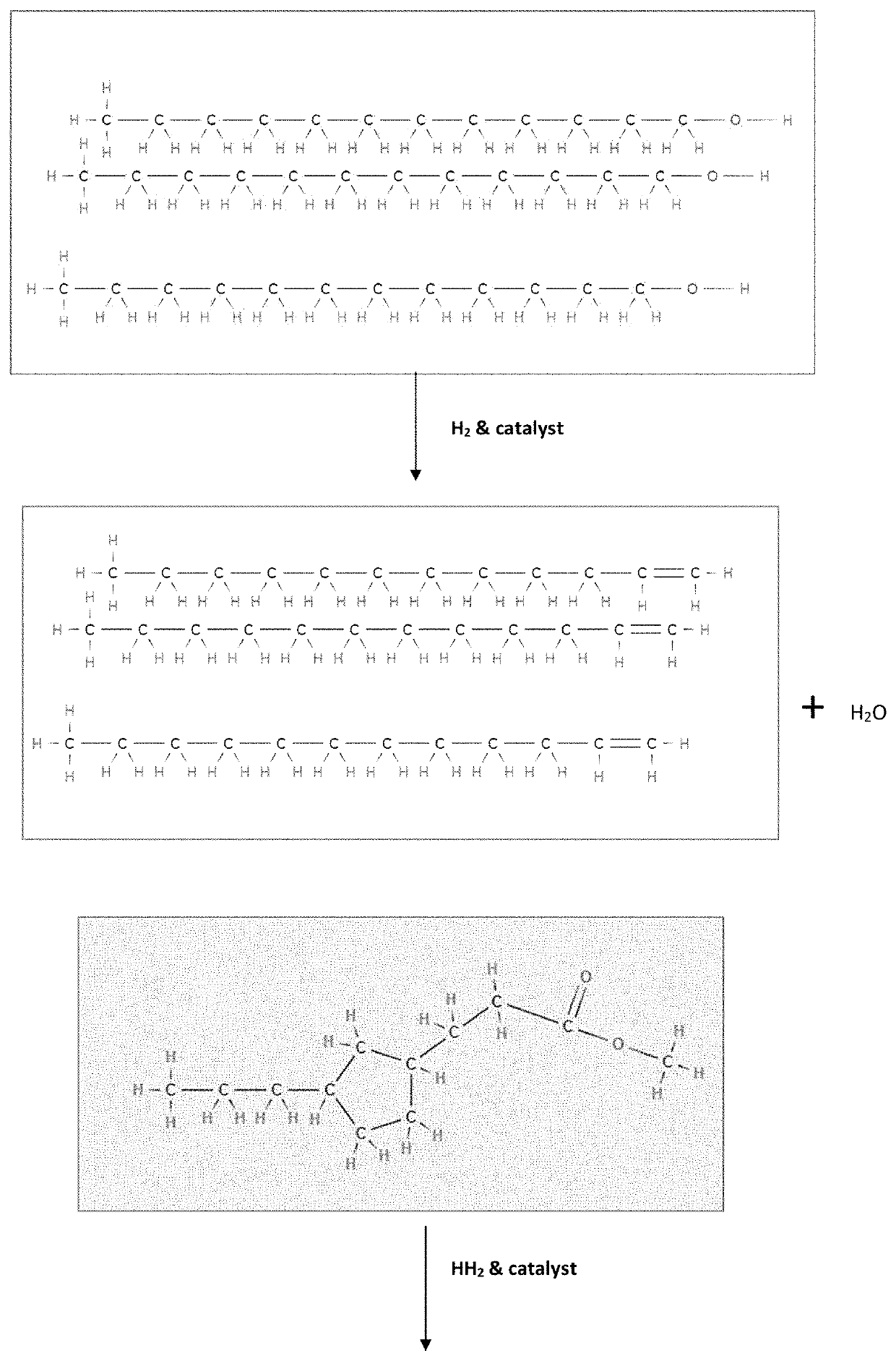

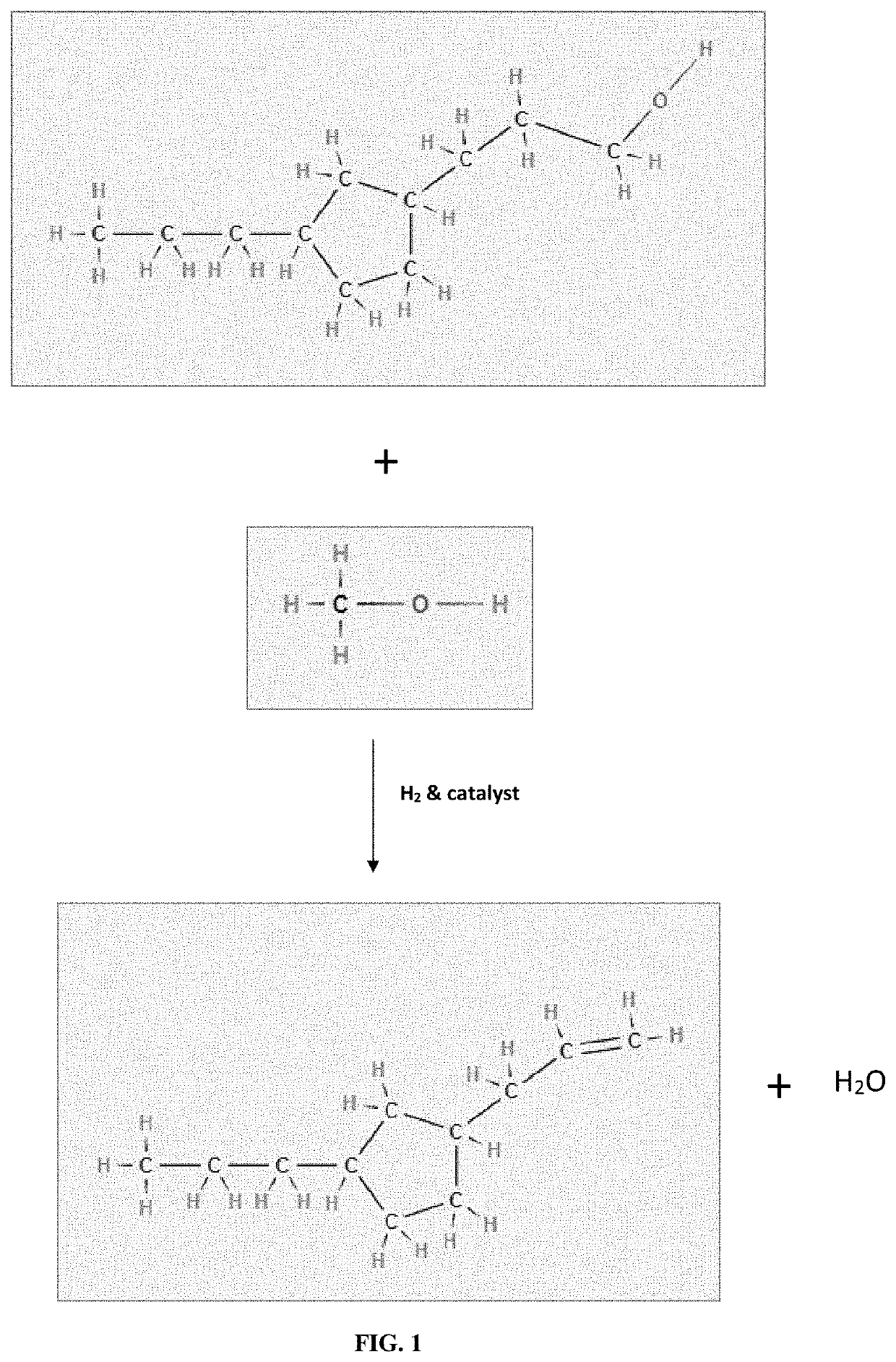

Method for manufacturing cyclododecanone

ActiveUS11358923B2Increase conversion rateSimple process configurationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsLaurolactamBiochemical engineering

The present invention relates to a method of preparing cyclododecanone. According to the present invention, a method of preparing cyclododecanone which allows implementation of a high conversion rate and minimization of production of unreacted materials and reaction by-products may be provided. In addition, the present invention implements a high conversion rate and a high selectivity even by a simplified process configuration, and thus may be usefully utilized in an economical method of preparing laurolactam, allowing commercially easy mass production.

Owner:HANWHA SOLUTIONS CORP

Process for simultaneous production of benzene lean gasoline and high purity benzene from cracked gasoline fraction

ActiveUS10105620B2Low costHigh purityTreatment with plural serial stages onlyDistillation purification/separationBenzeneExtractive distillation

Disclosed is a process for simultaneous production of benzene lean gasoline and recovery of high purity aromatics from narrow boiling light cracked gasoline fractions. The present invention provides a vacuum based two stage extractive distillation process, with pure NMP, for production of benzene lean gasoline (benzene content less than 0.4 Weight %) by recovery of high purity aromatics (purity more than 99 Weight %) from cracked gasoline fractions (boiling in the range of 40-90° C.) comprising benzene in the range of 10-30 weight % and close-boiling non-aromatic hydrocarbons like paraffins, iso-paraffins, olefins, di-olefins (including conjugated di-olefins), and naphthenes in the range of 70-90 weight % along with impurities containing but not limited to oxygenates, metals, chlorides, sulphur compounds, nitrogen compounds and organic peroxides.The present invention provides an improved extractive distillation process for simultaneous production of benzene lean gasoline and benzene rich product from cracked gasoline fraction, with higher recovery of better quality products along with lower utility requirements and investment costs.

Owner:COUNCIL OF SCI & IND RES

A method of using a manipulator to complete the ungrouping of cooked anode carbon blocks

ActiveCN106044186BSimple process configurationReduce investmentConveyor partsProduction lineMaterials science

The invention a method for disassembling wrought anode carbon blocks by using a mechanical arm. Equipment used in the method comprises a mechanical arm, a wrought anode carbon block conveying line, a disassembled carbon block storage basket and wrought anode carbon blocks. One end of the wrought anode carbon block conveying line and the disassembled carbon block storage basket are located in a working radius R of the mechanical arm; the wrought anode carbon block conveying line is used for stacking the wrought anode carbon blocks disassembled and clamped by the mechanical arm from the disassembled carbon block storage basket and conveying the wrought anode carbon blocks to a carbon block warehouse; the disassembled carbon block storage basket is used for storing the wrought anode carbon blocks clamped by a special clamp of a multifunctional roasting unit. Through the adoption of the method, the mechanical arm is used for disassembling the wrought anode carbon blocks; the method has the characteristics of simple structure, safety, reliability and convenience in use of the equipment; through the adoption of an automatic production line manner, a large quantity of manpower is reduced during operation; the capital investment is reduced; the cost of the enterprise is reduced; the production efficiency is improved; the requirements of practical production can be met; the method is suitable for large-scale popularization and application.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

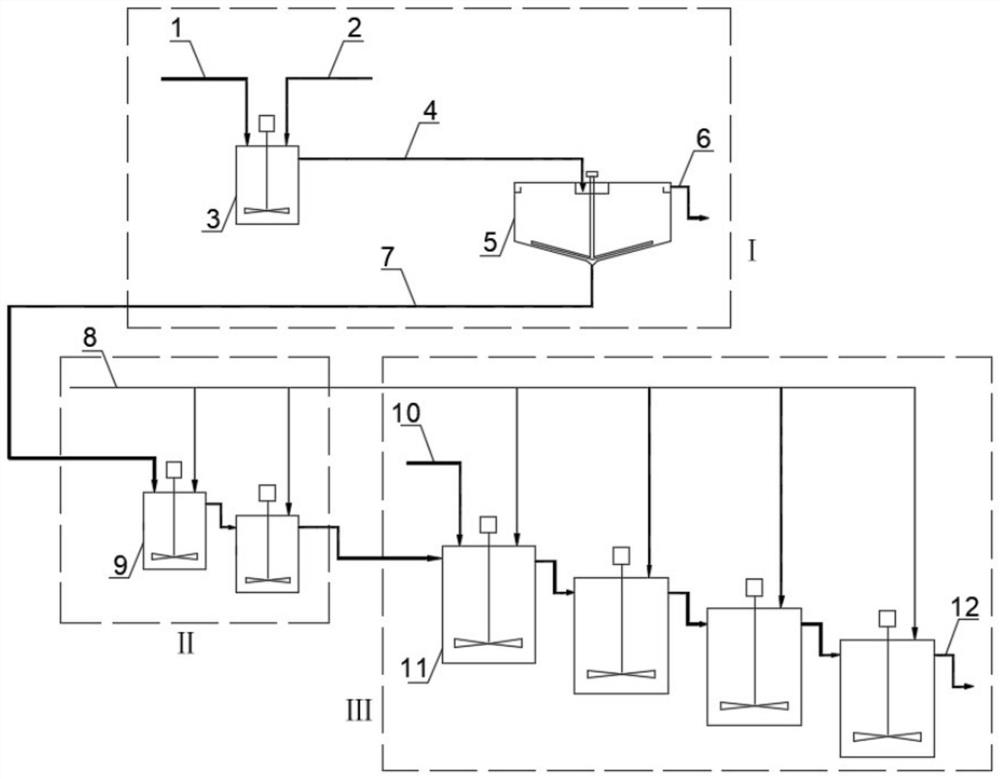

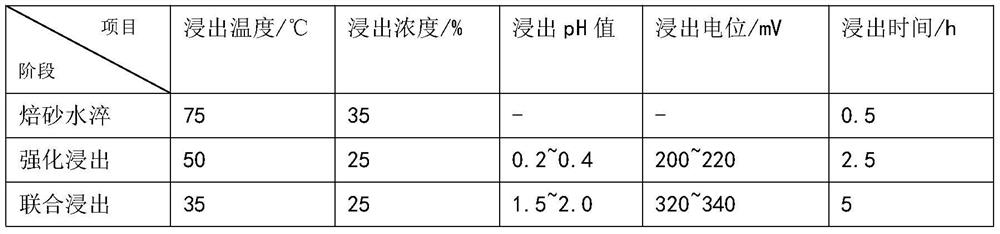

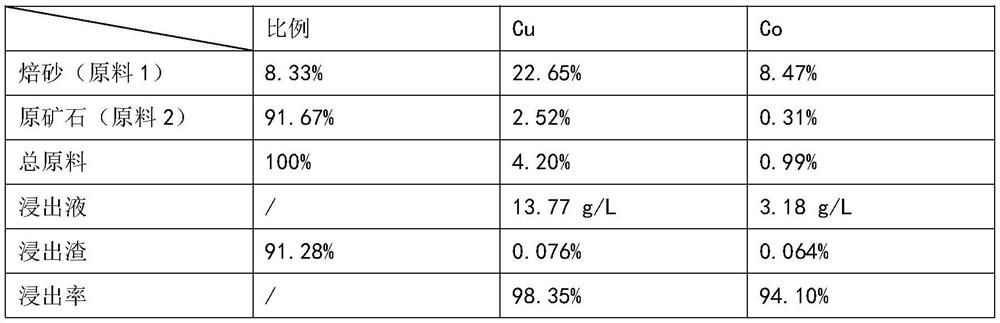

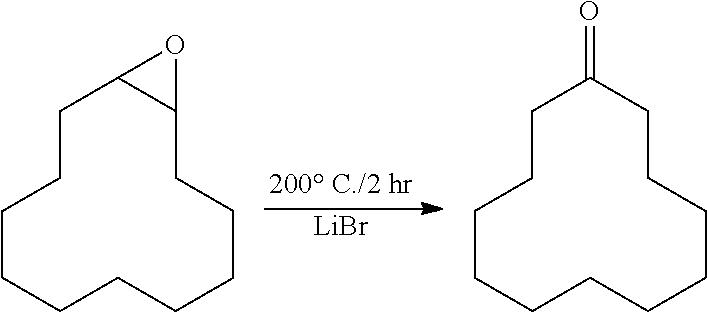

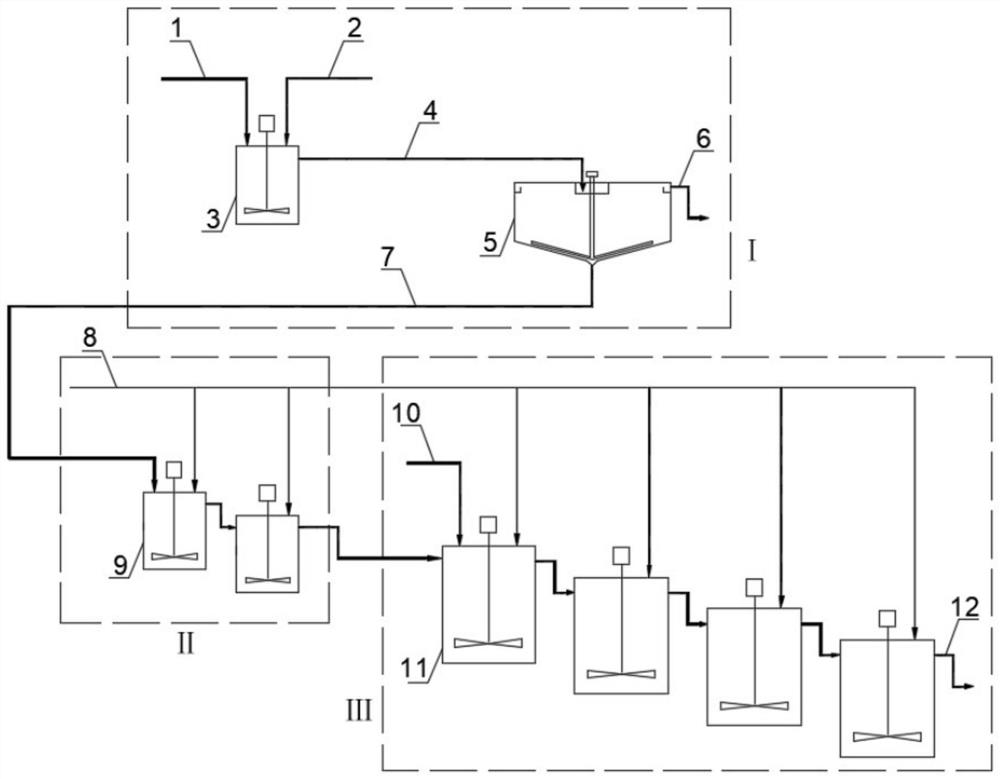

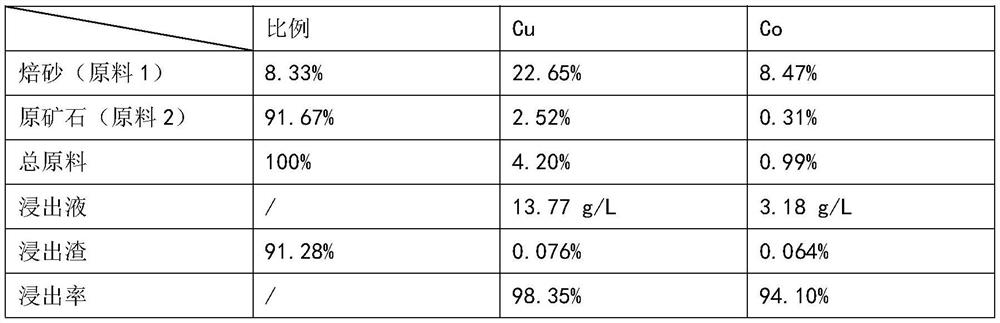

A combined extraction method for complex copper and cobalt raw materials

ActiveCN113025815BReduce loss rateSimple production processProcess efficiency improvementPregnant leach solutionEngineering

Owner:北方矿业有限责任公司

Method for completing group organization work of green anode carbon blocks by using manipulator

ActiveCN105819218ASimple process configurationReduce investmentConveyor partsProduction lineManipulator

The invention discloses a method for completing group organization work of green anode carbon blocks by using a manipulator. The method adopts the manipulator, a green anode carbon block conveying line, group-organized carbon block storage baskets and green anode carbon blocks, wherein one end of the green anode carbon block conveying line and the group-organized carbon block storage baskets are located in the working radius R range of the manipulator, the green anode carbon block conveying line is used for conveying the green anode carbon blocks in a carbon block warehouse to the working radius R range of the manipulator, and the group-organized carbon block storage baskets are used for the group-organized green anode carbon blocks received by the manipulator from the green anode carbon block conveying line to be placed. The method conducts group organization on the green anode carbon blocks through the manipulator and has the advantages of being simple in device structure, safe, reliable and convenient to use. By adopting the automatic production line, lots of manpower resources for operation are decreased, fund input is saved, the costs of enterprises are reduced, the production efficiency is improved, the actual production demands are met, and the method is suitable for large-scale popularization and application.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

High-purity nitrogen equipment

ActiveCN101929790BTake advantage ofImprove reliabilitySolidificationLiquefactionNitrogenProcess engineering

The invention provides high-purity nitrogen equipment which comprises a preprocessing system, a purifying system and a fractionating tower, wherein the fractionating tower comprises a turboexpander, a main heat exchanger and a subcooler for heat exchange, a rectifying tower and a condensation evaporator, the rectifying tower comprises an upper tower and a lower tower, the outlet of the purifying system is connected with the air inlet of the lower tower through a pipeline, and the pipeline passes through the main heat exchanger; the lower tower is also provided with an oxygen-enriched liquid air outlet for oxygen-enriched liquid air generated by rectification to flow out, the oxygen-enriched liquid air outlet is connected with the purifying system through a pipeline, and the pipeline passes through the main heat exchanger; and the upper tower is provided with a nitrogen gas outlet, and the pipeline connected with the outlet passes through the main heat exchanger. In the invention, the pipeline of enriched oxygen, the pipeline of raw material air and the pipeline of nitrogen gas are simultaneously connected with the main heat exchanger, so that the cold quantities of the enriched oxygen and the nitrogen gas are fully utilized, and the high-purity nitrogen equipment saves the energy and protects the environment; meanwhile, the enriched oxygen is sent into the expander for refrigeration, and the high-purity nitrogen equipment has the advantages of reasonable structure, material saving and simple flow configuration.

Owner:苏州制氧机股份有限公司

Method for manufacturing cyclododecanone

ActiveUS20220064094A1High conversion rateRatio decreaseOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsSide productProcess engineering

The present invention relates to a method of preparing cyclododecanone. According to the present invention, a method of preparing cyclododecanone which allows implementation of a high conversion rate and minimization of production of unreacted materials and reaction by-products may be provided. In addition, the present invention implements a high conversion rate and a high selectivity even by a simplified process configuration, and thus may be usefully utilized in an economical method of preparing laurolactam, allowing commercially easy mass production.

Owner:HANWHA SOLUTIONS CORP

Combined extraction method of complex copper and cobalt raw materials

ActiveCN113025815AReduce loss rateSimple production processProcess efficiency improvementHigh concentrationPregnant leach solution

The invention relates to a combined extraction method of complex copper and cobalt raw materials, and belongs to the field of metallurgical mines. The combined extraction method is divided into three steps of calcine water quenching, calcine reinforced leaching and calcine and raw ore combined leaching, the three procedures are mutually independent and organically unified, a water quenching leachate is independently thickened to obtain a high-concentration leachate, the amount of metal entering the subsequent leaching and washing procedures is reduced, and the comprehensive recovery rate of the metal is ensured; high-grade calcine is subjected to enhanced leaching through a high-acidity and high-reducing-agent leaching agent, and the leaching rate of the calcine is enhanced; and the residual acid and the residual reducing agent in the enhanced leaching process can continuously participate in the leaching process of the combined leaching procedure, so that the utilization efficiency of the leaching agent is improved. According to the combined extraction method, the same metal and different forms of raw materials share the same production line for combined extraction, the production process is greatly simplified, and meanwhile the combined extraction method has the advantages of being high in leaching rate, low in metal loss rate and the like.

Owner:北方矿业有限责任公司

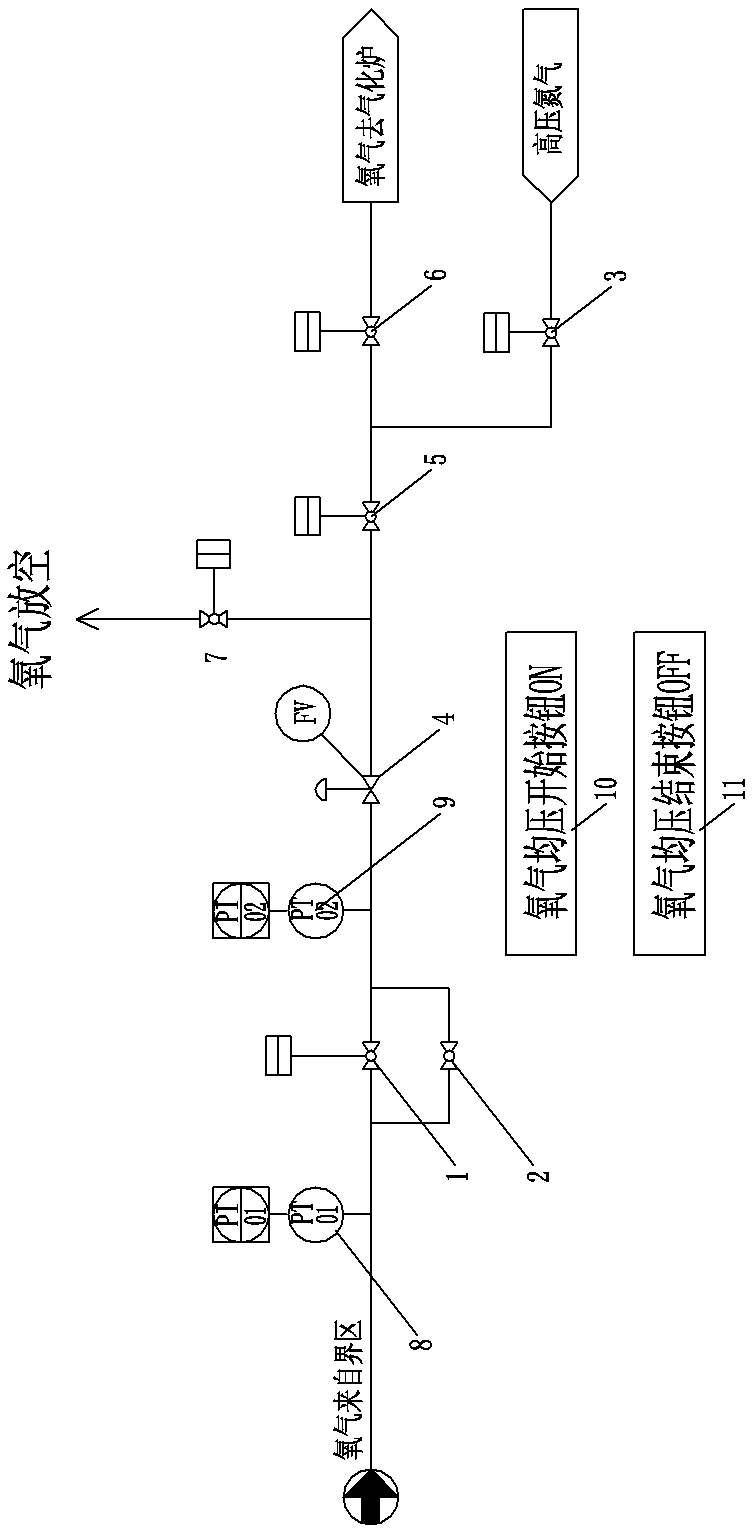

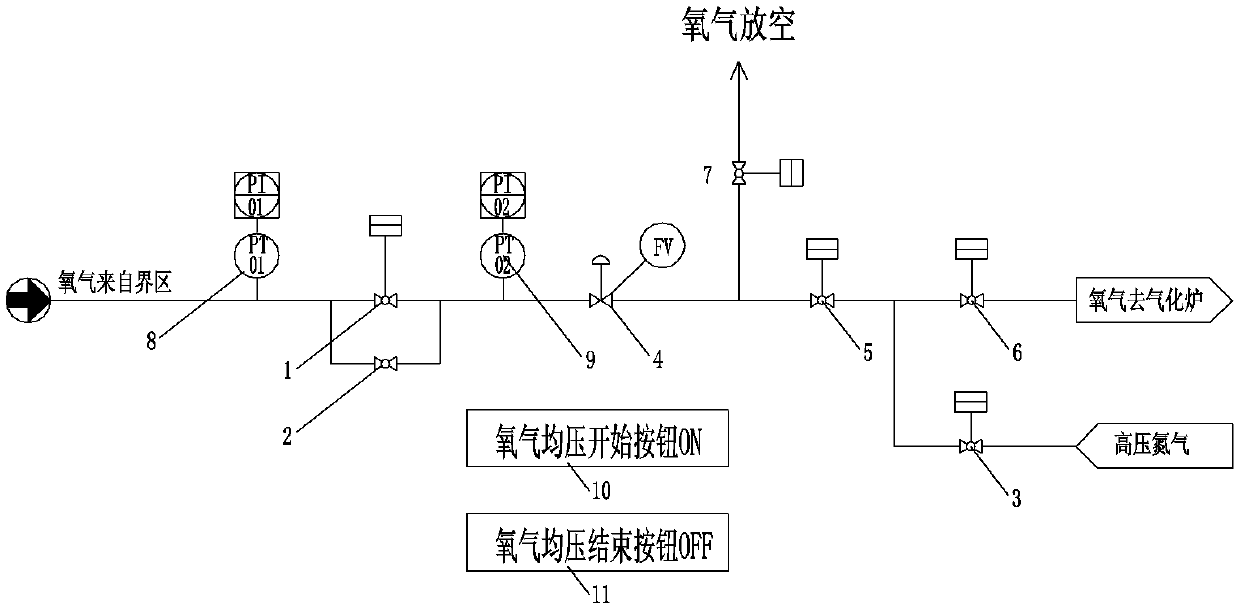

A method for starting up a gasifier to meet oxygen

ActiveCN105733684BEasy to controlReduce operational riskGasification processes detailsCombustible gas productionNitrogenPressure difference

The invention discloses a start-up oxygen introduction method for a gasification furnace. The start-up oxygen introduction method comprises the following steps: (1) constructing a pressurizing pipeline; (2) keeping an oxygen boundary valve closed, opening an oxygen flow control valve for adjustment, opening an oxygen upstream nitrogen blockage valve, closing an oxygen downstream nitrogen blockage valve, closing an oxygen emptying valve, opening a high-pressure nitrogen pressurizing valve to perform nitrogen pressurization on the pipeline behind the oxygen boundary valve, and closing the high-pressure nitrogen pressurizing valve when the pressure difference of the oxygen boundary valve prior to and after the opening of the valve is less than 0.3 MPa, to complete a pre-startup stage pressure averaging process; (3) closing the oxygen flow control valve for adjustment, closing the oxygen upstream nitrogen blockage valve and the oxygen downstream nitrogen blockage valve, opening the oxygen emptying valve, opening the oxygen boundary valve when the pressure difference of the oxygen boundary valve prior to and after the opening of the valve is less than 0.4 MPa to introduce oxygen, and controlling the oxygen flow under the adjustment of the oxygen flow control valve, to complete the oxygen introduction process. According to the start-up oxygen introduction method, nitrogen is used for averaging the pressure, so that high-flowing-speed oxygen cannot be generated during pressure averaging with the oxygen, and the operation risk of the start-up oxygen introduction process of the gasification furnace is reduced.

Owner:SINOPEC NANJING ENG & CONSTR +1

Image processor performing noise reduction processing, imaging apparatus equipped with the same, and image processing method for performing noise reduction processing

ActiveUS9426437B2Reduce colorSimple process configurationImage enhancementTelevision system detailsImaging processingFalse color

An image processor includes a first image creator which creates first noise-processed image data by performing noise reduction processing on data on one image acquired by an imaging device, a second image creator which creates second noise-processed image data by performing noise reduction processing corresponding to a false color generated in the first noise-processed image data, and an image synthesizer which performs false color reduction by synthesizing the first noise-processed image data and the second noise-processed image data.

Owner:RICOH KK

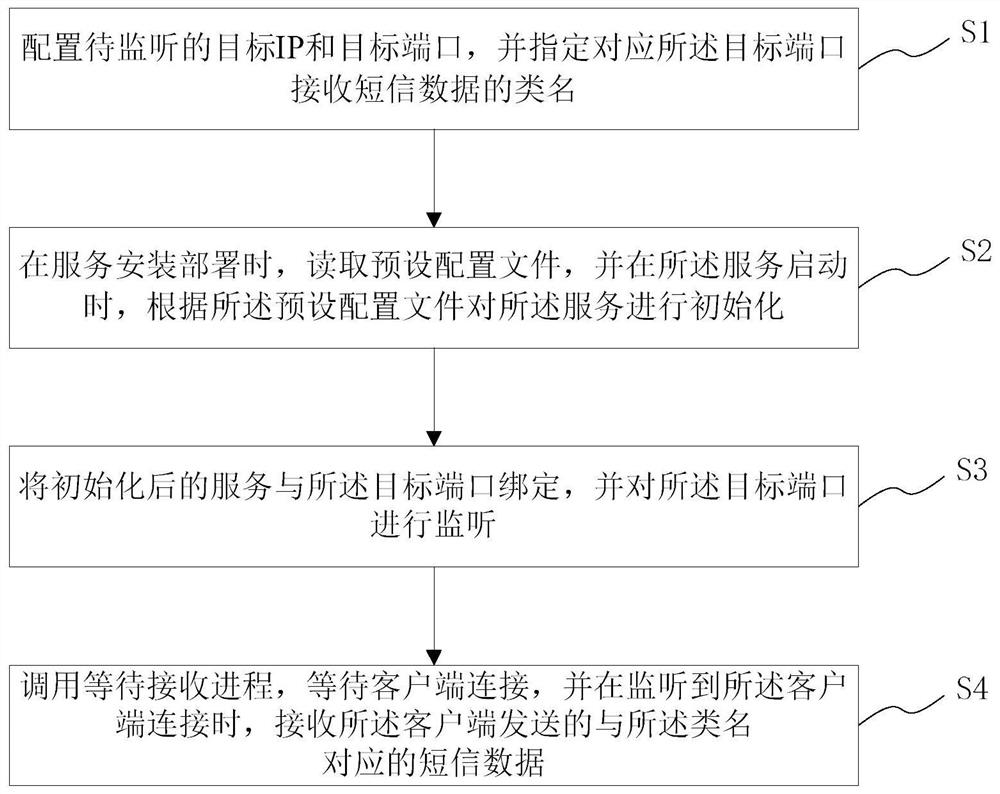

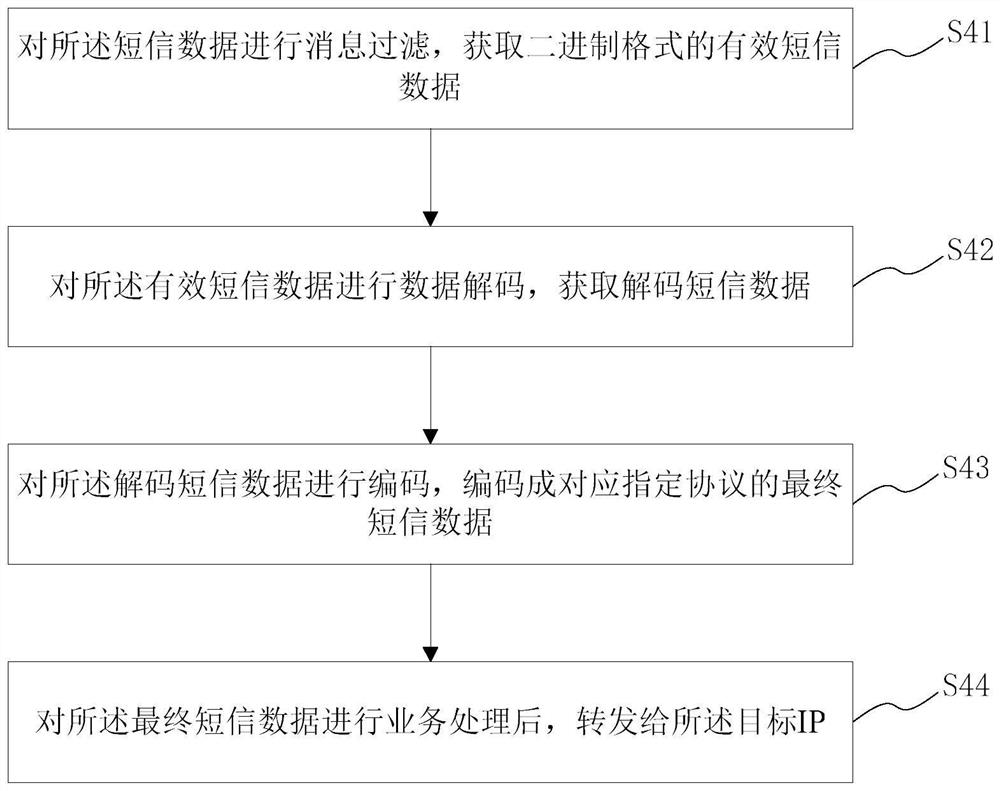

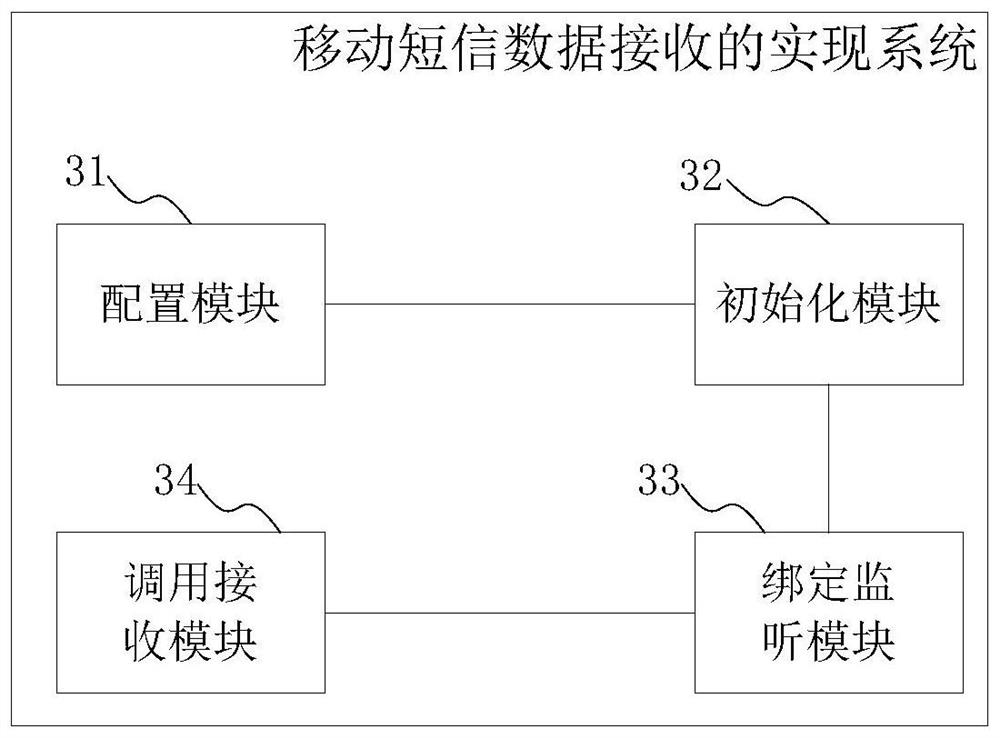

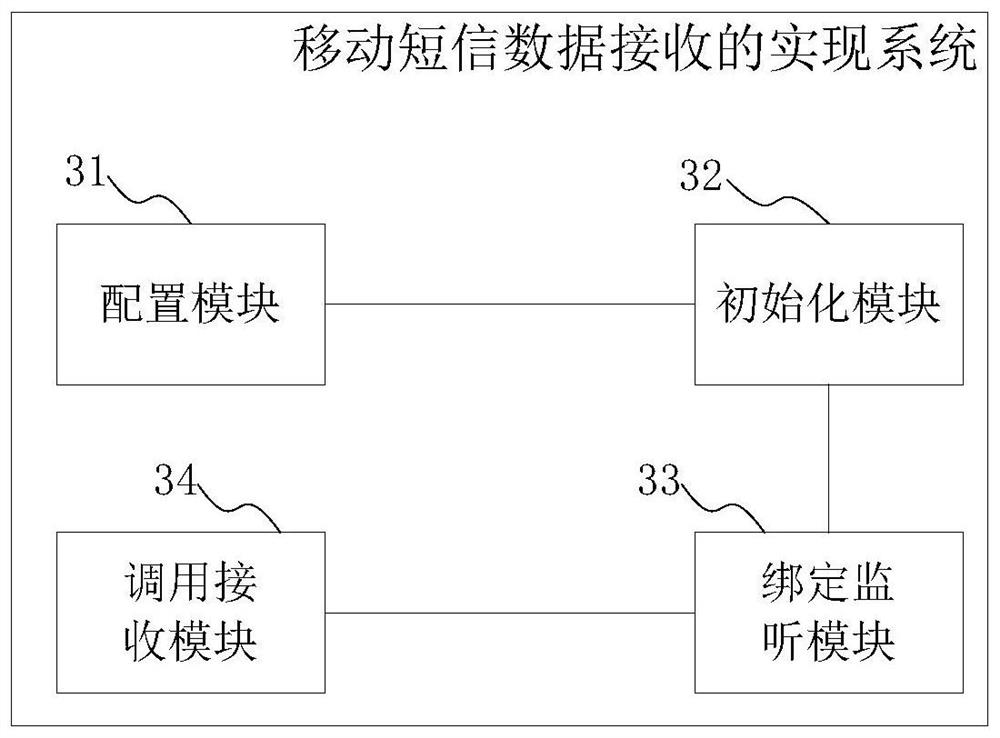

Method, system, medium and server for receiving mobile short message data

ActiveCN112218253BStay onlineDon't worry about blockingMessaging/mailboxes/announcementsEngineeringClient

Owner:SHANGHAI PATEO INTERNET TECH SERVICE CO LTD

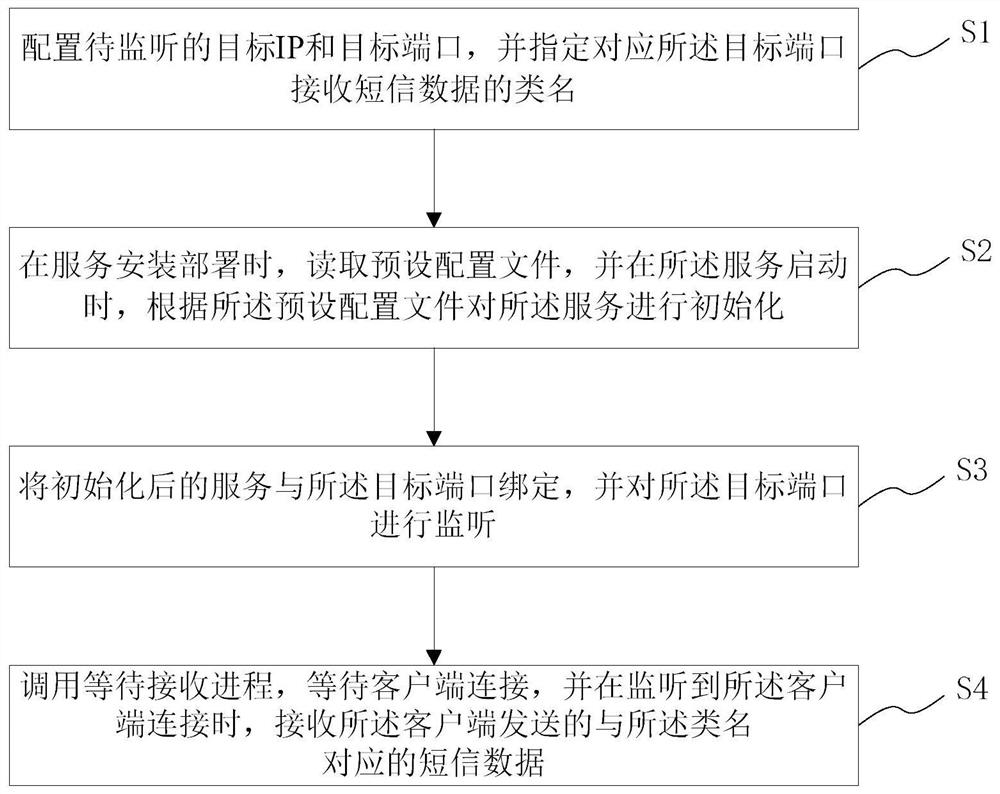

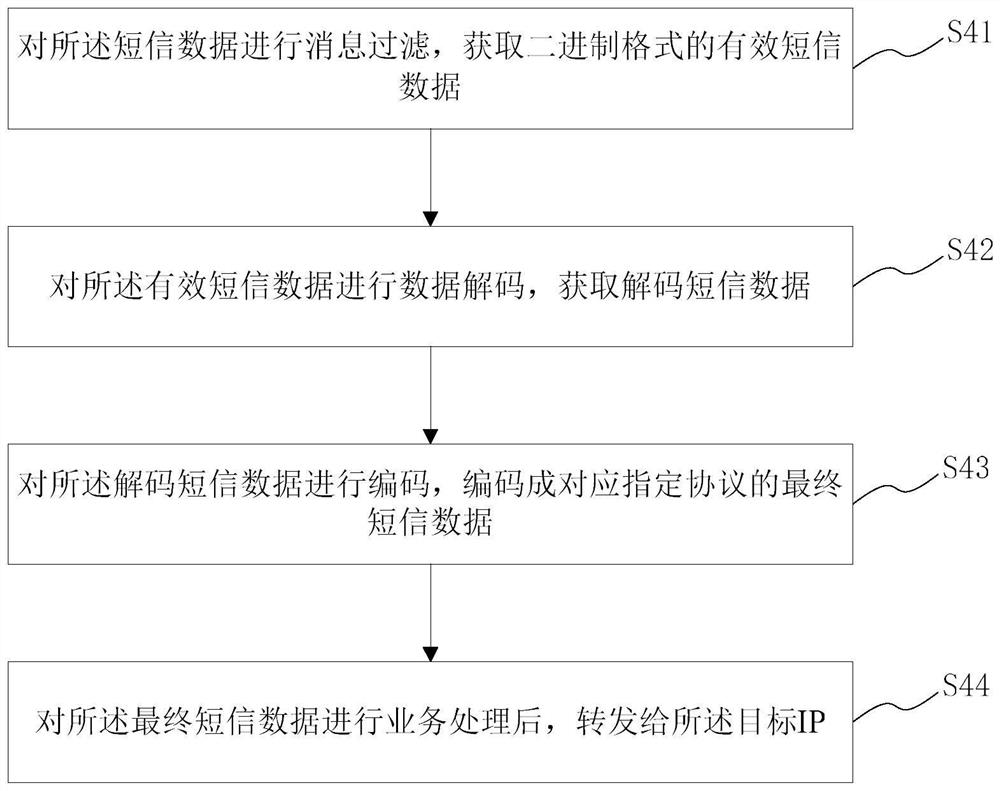

Mobile short message data receiving implementation method and system, medium and server

ActiveCN112218253AStay onlineDon't worry about blockingMessaging/mailboxes/announcementsEngineeringReal-time computing

The invention provides a mobile short message data receiving implementation method and system, a medium and a server. The implementation method comprises the following steps: configuring a target IP and a target port to be monitored, and specifying a class name of short message data received by the corresponding target port; reading a preset configuration file when the service is installed and deployed, and initializing the service according to the preset configuration file when the service is started; binding the initialized service with a target port, and monitoring the target port; callinga receiving waiting process, waiting for client connection, and receiving short message data corresponding to the class name sent by the client when the client connection is monitored. According to the invention, the monitoring port is established on the short message docking platform to monitor the mobile operator gateway in real time, the short message docking platform does not need to keep an online state all the time, message congestion does not need to be worried about, and the effects of saving development cost, simplifying configuration and improving short message data processing efficiency are achieved.

Owner:SHANGHAI PATEO INTERNET TECH SERVICE CO LTD

Production of Linear Alpha Olefins

ActiveUS20220098130A1Low costSimple process configurationDistillation purification/separationLiquid hydrocarbon mixture productionPtru catalystHydrogenation reaction

The present invention provides a novel route for synthesis and production of linear alpha olefins (LAO) and central olefins from the feedstock comprising fatty acids, triglycerides and esters of fatty acids, and mixture thereof through controlled hydrogenolysis, hydrogenation and dehydration reactions simultaneously in a hydro processing reactor containing a catalyst system having dual site—a metallic site for hydrogenation / reduction reaction under hydrogen environment, and an acidic site for conversion of alcohol to olefin via E1 or E2 reaction mechanism.

Owner:INDIAN OIL CORPORATION

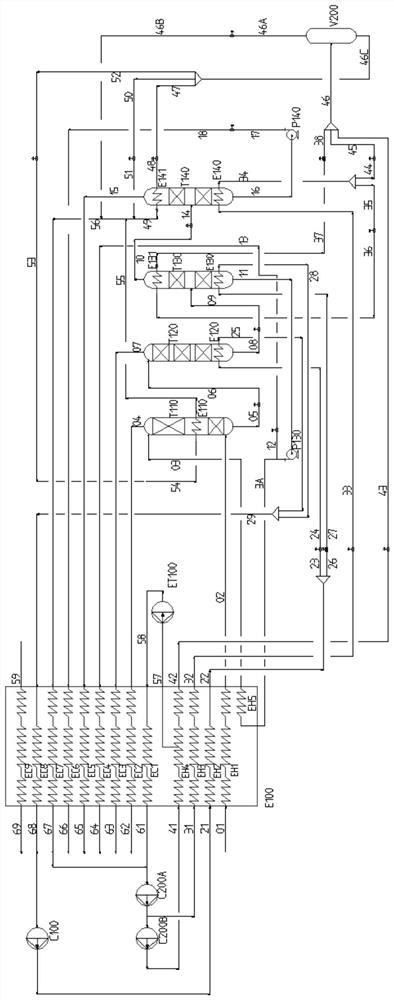

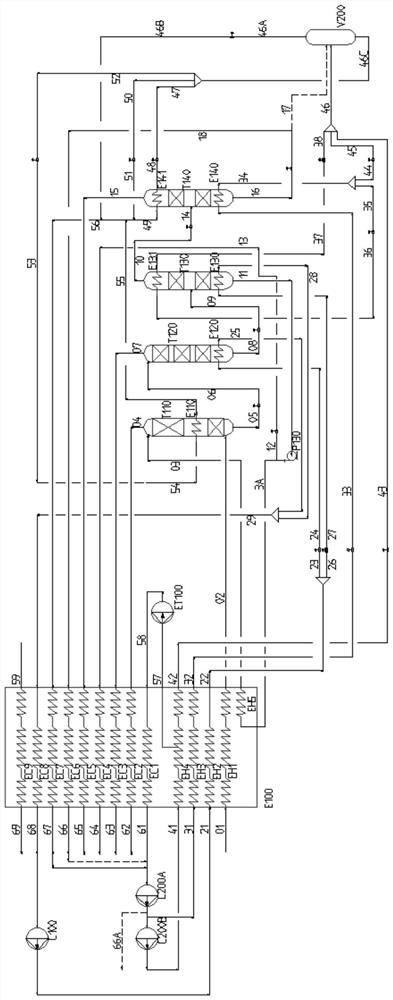

Dual-refrigeration cycle methane washing synthesis gas cryogenic separation device and separation method

PendingCN113862051AMeet gas demandModerate circulationMechanical apparatusCompression machines with non-reversible cycleSyngasProcess engineering

The invention provides a dual-refrigeration cycle methane washing synthesis gas cryogenic separation device and a separation method. The separation device comprises a methane washing tower, a flash tower, a first separation tower, a second separation tower, a first circulating refrigeration system and a second circulating refrigeration system, wherein the methane washing tower, the flash tower, the first separating tower and the second separating tower are sequentially communicated, the first circulating refrigerating system comprises a methane circulating refrigerating system, and the second circulating refrigerating system comprises a nitrogen circulating refrigerating system or a carbon monoxide circulating refrigerating system. The invention also provides a separation method which is carried out in the separation device. According to the method, the synthesis gas with high methane content and nitrogen content can be efficiently separated, a hydrogen-rich product, a pure methane product and a pure carbon monoxide product are prepared at the same time, and the relatively high carbon monoxide recovery rate is ensured while the energy consumption is greatly reduced.

Owner:BEIJING PETROCHEM ENG

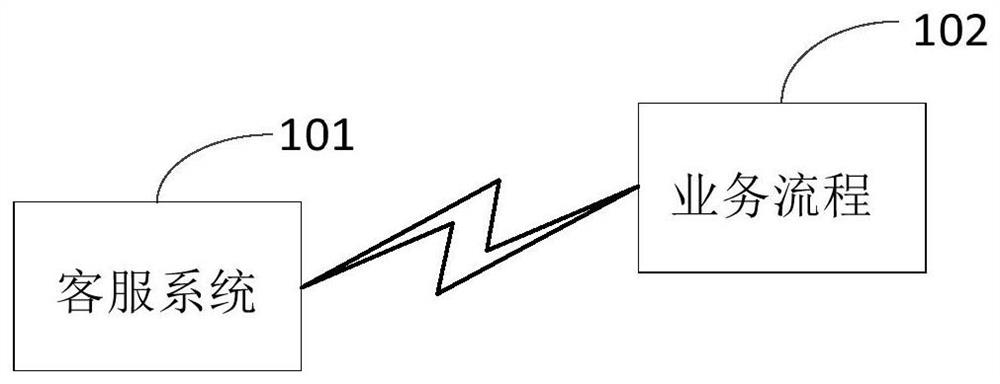

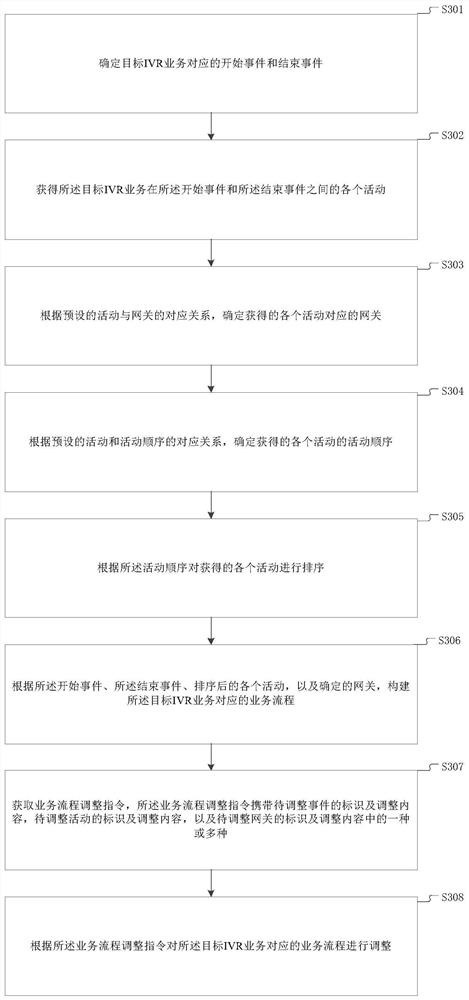

Business process construction method and equipment

ActiveCN110351440BHelp to deal withAccurate serviceAutomatic exchangesPersonalizationService experience

Embodiments of the present invention provide a service process construction method and device, the method comprising: determining the start event and end event corresponding to the target IVR service; obtaining each activity of the target IVR service between the start event and the end event; The corresponding relationship between activities and gateways determines the gateways corresponding to the obtained activities; according to the above-mentioned start event, end event, obtained activities, and determined gateways, construct the business process corresponding to the target IVR service. The method flow configuration provided by this embodiment is simple, and can effectively help relevant personnel to complete the IVR flow construction conveniently; at the same time, standardize the IVR construction flow, which is helpful for the realization and identification of the back-end code and subsequent data processing; in addition, the flow configuration is easy Expansion makes the IVR function more personalized and intelligent, meets the diversified requirements of existing users for the IVR process, enables users to obtain accurate services effectively and conveniently, and improves customer service experience.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

A method of using a manipulator to complete the grouping of raw anode carbon blocks

ActiveCN105819218BSimple process configurationReduce investmentConveyor partsProduction lineManipulator

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com