High efficiency detoxifcation method and device of organic wastewater

An organic wastewater and high-efficiency technology, which is applied in the fields of light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high treatment cost, complicated process control and equipment, and difficult to adapt, so as to reduce the treatment cost and eliminate the speed quickly. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

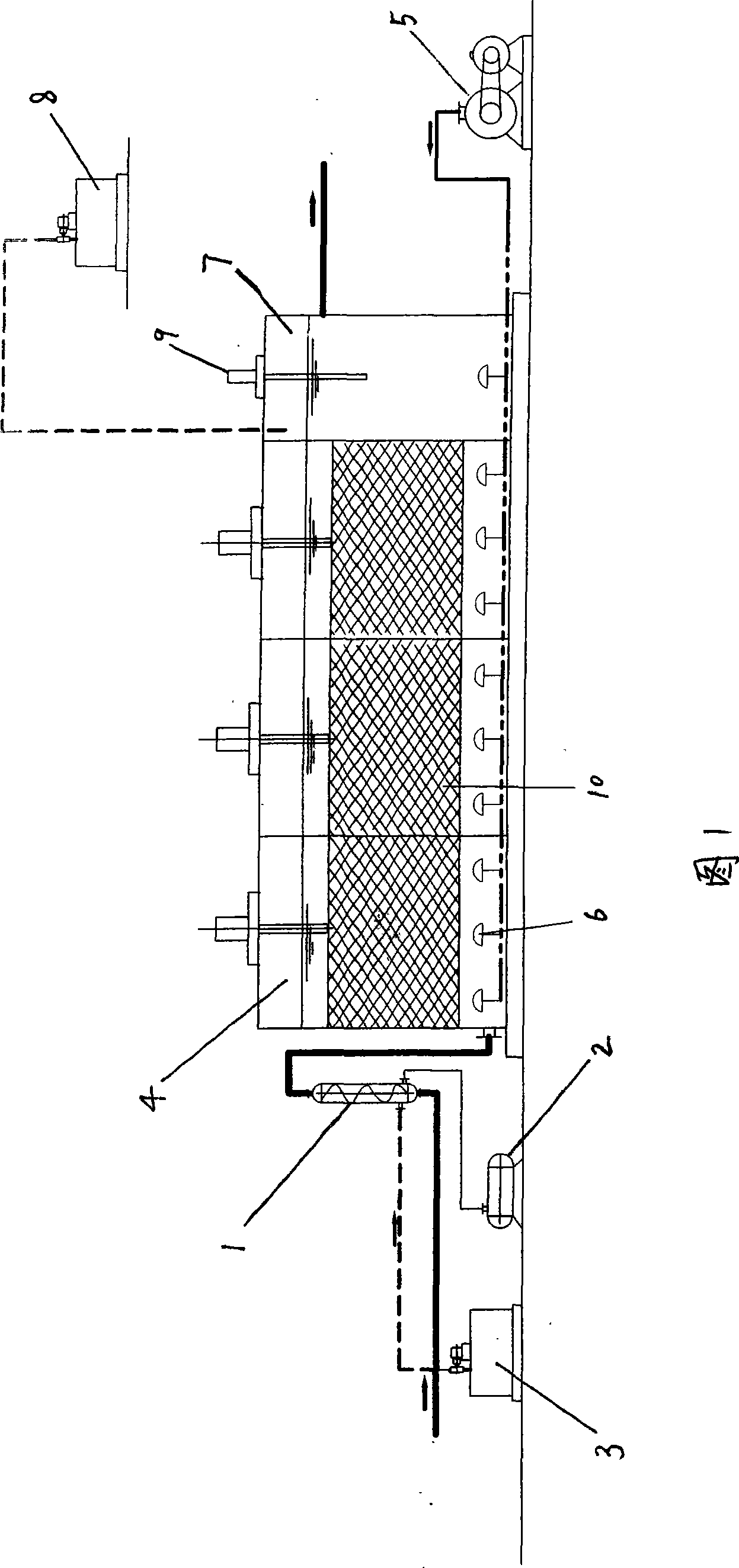

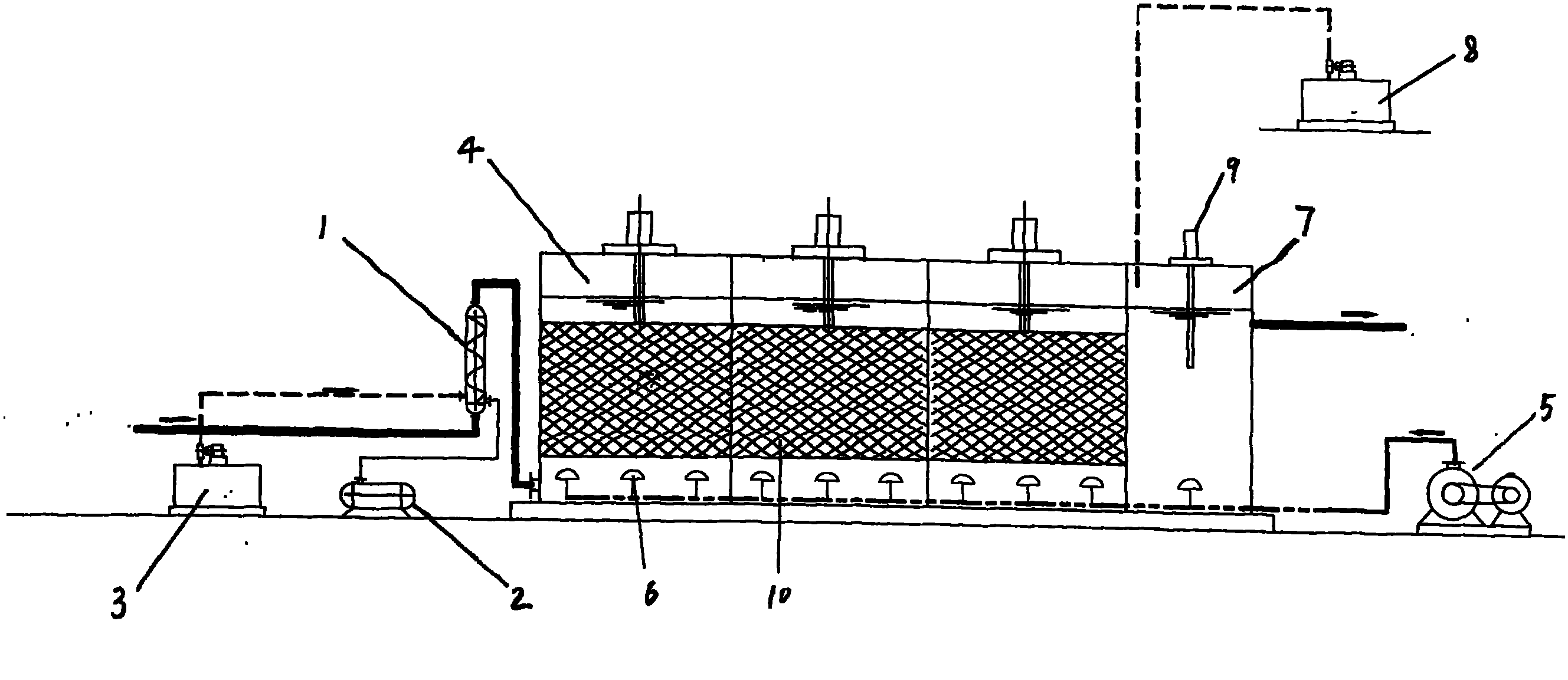

[0024] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings: The efficient detoxification method of organic wastewater according to the present invention mainly includes three steps of mixing, catalytic reaction and oxidant reduction, and the organic wastewater to be treated is passed into inside a pipeline mixer with H 2 o 2 and O 3 Fully mixed, then enter a catalytic reactor composed of a catalytic reaction unit, under the induction of ultraviolet light UV, the catalytic reaction is carried out under the action of a catalyst with activated carbon as a carrier, and then enter an oxidant reduction unit, after adding the reducing agent After the oxidant is reduced, the waste water that meets the requirements is drawn out.

[0025] The organic wastewater to be treated according to the present invention is first collected in a sump or tank, and the pH is controlled at 5-11, and then sent into a pipeline mixer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com