Dual-refrigeration cycle methane washing synthesis gas cryogenic separation device and separation method

A separation device and synthesis gas technology, applied in the field of gas cryogenic separation, can solve the problems of high energy consumption of methane washing process, low CO recovery rate, high equipment investment, etc. Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

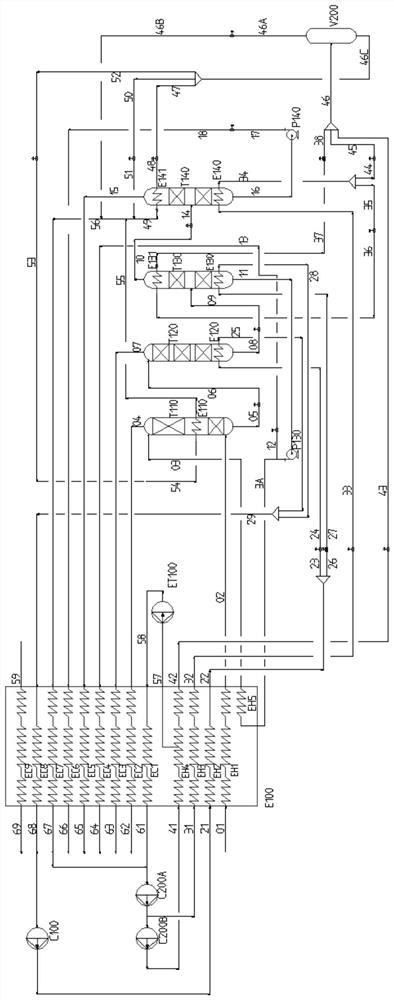

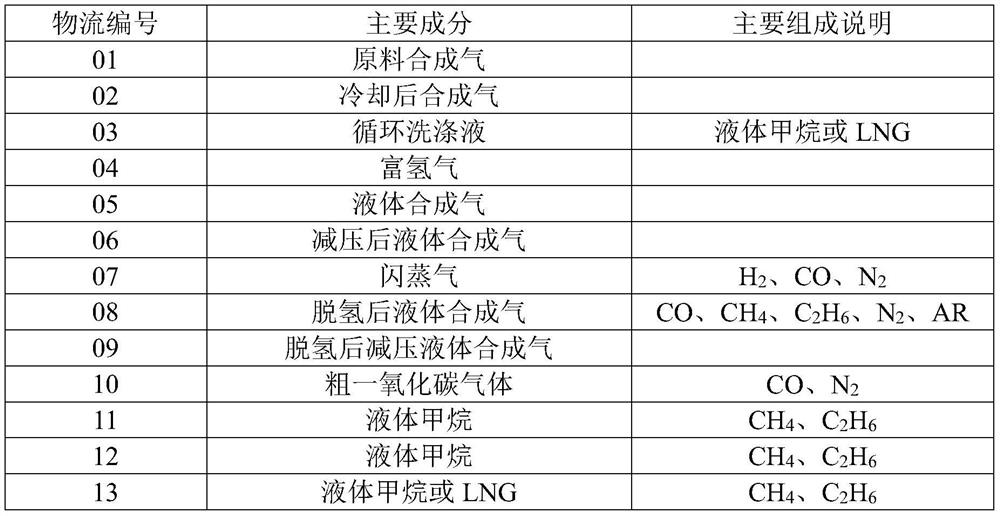

[0076] This embodiment provides a methane and nitrogen double refrigeration cycle methane washing synthesis gas cryogenic separation device. The structure of the separation device is as figure 1 As shown, it includes methane scrubber T110, flash tower T120, first separation tower T130, second separation tower T140, first cycle refrigeration system, second cycle refrigeration system, methane pump P130, carbon monoxide pump P140, main heat exchanger E100 and cold box.

[0077] The methane scrubber T110 is used for the preliminary separation of hydrogen in the synthesis gas, avoiding the problems of lower tower top temperature and higher energy consumption caused by high hydrogen content in the synthesis gas, and is conducive to maintaining the stability of the tower top of the subsequent separation tower.

[0078] The flash tower T120 is used to further perform gas-liquid mass transfer in the liquid-phase syngas treated by the methane scrubber T110 to realize the separation of ...

Embodiment 2

[0101] This embodiment provides a methane and nitrogen double refrigeration cycle methane washing synthesis gas cryogenic separation method, which is carried out in the separation device of embodiment 1. Such as figure 1 As shown, the method includes the following steps:

[0102] The raw synthesis gas (stream 01) of about 3.5 MPaG is cooled by the hot stream channel EH1 and then converted into stream 02 and sent to the gas inlet of the methane scrubber T110 tower. The synthesis gas is subjected to gas-liquid separation at the bottom of the methane scrubber T110 to obtain liquid-phase synthesis gas (stream 05) and rising gas. The ascending gas is exchanged with the liquid methane as the circulating scrubbing liquid in the top reflux system, the non-hydrogen gas in the ascending gas is absorbed by the liquid methane, and the unabsorbed gas forms hydrogen-rich gas (stream 04) from the gas outlet at the top of the tower Discharged and then reheated by the cold stream channel EC2...

Embodiment 3

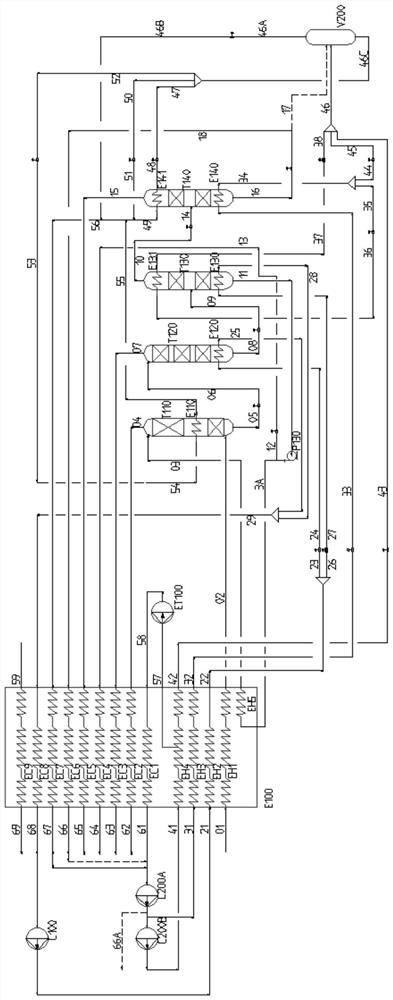

[0119] This embodiment provides a methane and carbon monoxide dual refrigeration cycle methane washing synthesis gas cryogenic separation device. The structure of this separation device is similar to the structure of the separation device provided in Example 1, and the main difference is that the separation device of this embodiment does not contain a carbon monoxide pump P140; the liquid outlet of the second separation tower T140 can be connected with the inlet of the gas-liquid separation tank V200 on the one hand. On the other hand, it can communicate with the inlet of the first-stage compressor C200A in the second cycle refrigeration system through the cold flow channel EC6; the outlet of the first-stage compressor C200A can directly communicate with the CO product pipeline network.

[0120] Specifically, the structure of the separation device provided in this embodiment is as follows figure 2 As shown, including methane scrubber T110, flash tower T120, first separation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com