Unmanned-aerial-vehicle paddle die processing method

A mold processing and UAV technology, which is applied in the field of UAV blade mold processing, can solve the problems affecting the dynamic balance and static balance of the blade, the lift of the UAV, and the balance of the blade, so as to improve the lift, Save the cost of adding and repairing molds and avoid the effect of secondary process errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

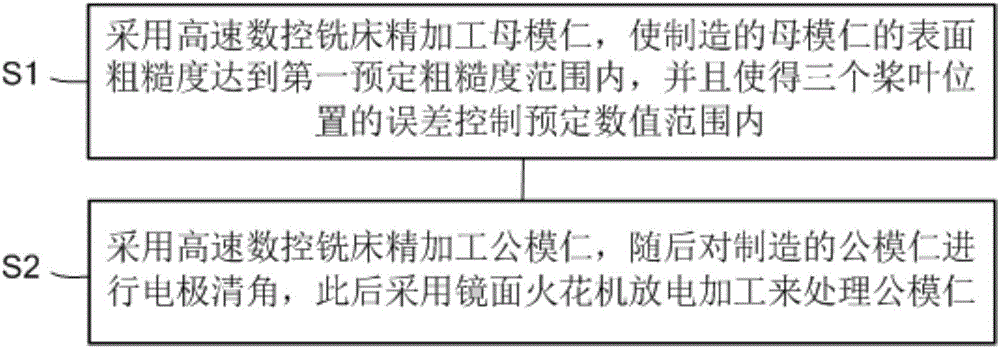

[0026] figure 1 It is a flow chart of a method for processing a UAV blade mold according to a preferred embodiment of the present invention.

[0027] Specifically, as figure 1 As shown, the UAV blade mold processing method according to a preferred embodiment of the present invention includes:

[0028] Machining step S1 of the master mold core: use a high-speed CNC milling machine to finish the master mold core, so that the surface roughness of the manufactured master mold core reaches the first predetermined roughness range, and the errors of the three blade positions are controlled within the predetermined value range ;

[0029] For example, in the processing step of the master mold core, the surface roughness of the manufactured master mold core should be within Ra1.6.

[0030] For example, in the processing step of the core of the master mold, the errors of the positions of the three paddles are controlled within a range of no more than 0.01MM.

[0031] Male die core pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com