Sodium ion total battery and preparation method thereof

A full battery and sodium ion technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problem of insignificant electrochemical performance of polyanionic sodium ferric sulfate cathode materials, failure to obtain sodium storage capacity, cycle Stability, high rate performance, low conductivity of the surface carbon coating, etc., to achieve the effect of improving cycle stability, inhibiting the formation of oxidation and impurity phases, and easy to adjust the mass percentage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: prepare Na 3 Fe 2 (SO 4 ) 3 F / CNF-5% cathode material

[0044] 1. Vacuum-dry ferrous sulfate heptahydrate in an oven at 200°C for 10 hours to obtain anhydrous ferrous sulfate.

[0045] 2. Weigh 0.4675g of sodium sulfate, 1.00g of anhydrous ferrous sulfate, 0.1379g of sodium fluoride and 0.0803g of carbon fiber, add them to a 50mL zirconia ball mill jar, add 33g of zirconia balls, and set the ball-to-material ratio to 20 : 1, fill into argon protection, carry out ball milling, ball milling rotation rate is 200r / min, revolution rate is 500r / min, ball milling time is 6h.

[0046] 3. Transfer the ball-milled composite precursor to a tube furnace, heat-treat it under an argon protective atmosphere, and calcinate it at 350°C for 5 hours, and grind the calcined product into powder to obtain a composite material containing 5% carbon fiber. for Na 3 Fe 2 (SO 4 ) 3 F / CNF-5% cathode material.

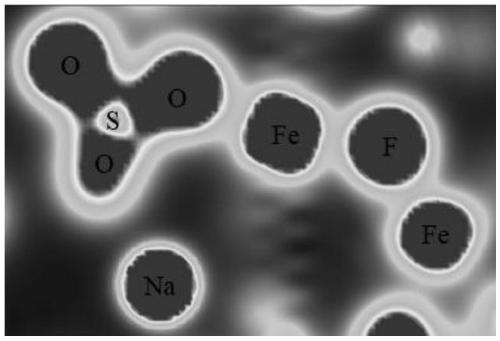

[0047] figure 1 for Na 3 Fe 2 (SO 4 ) 3 The electron cloud...

Embodiment 2

[0050] Embodiment 2: prepare Na 3 Fe 2 (SO 4 ) 3 F / CNF-2% cathode material

[0051] 1. Vacuum-dry ferrous sulfate heptahydrate in an oven at 200°C for 10 hours to obtain anhydrous ferrous sulfate.

[0052] 2. Weigh 0.4675g of sodium sulfate, 1.00g of anhydrous ferrous sulfate, 0.1379g of sodium fluoride and 0.0321g of carbon fiber, add them to a 50mL zirconia ball mill jar, add 33g of zirconia balls, and set the ball-to-material ratio to 20 : 1, fill into argon protection, carry out ball milling, ball milling rotation rate is 200r / min, revolution rate is 500r / min, ball milling time is 6h.

[0053] 3. Transfer the ball-milled composite precursor to a tube furnace, heat-treat it under an argon protective atmosphere, and calcinate it at 350°C for 5 hours, and grind the calcined product into powder to obtain a composite material containing 2% carbon fiber, record for Na 3 Fe 2 (SO 4 ) 3 F / CNF-2% cathode material.

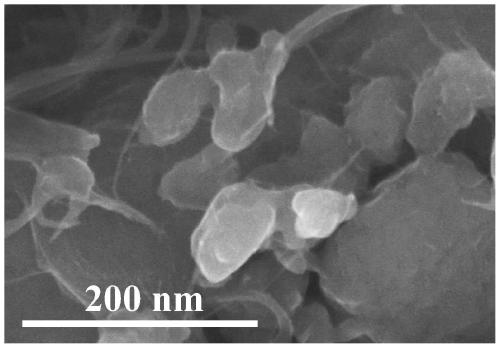

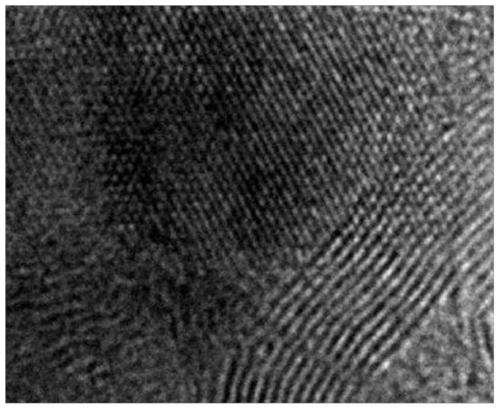

[0054] Na 3 Fe 2 (SO 4 ) 3 The SEM image and HRTEM i...

Embodiment 3

[0055] Embodiment 3: Preparation of sodium ion full battery

[0056] 1. Weigh Na 3 Fe 2 (SO 4 ) 3 F / CNF-5% positive electrode material 0.8g, according to the mass ratio of 8:1:1, respectively weigh 0.1g of acetylene black as conductive carbon and 0.1g of polyvinylidene fluoride as binder, and disperse the above three materials in N-methylpyrrolidone solvent, mixed uniformly, coated on an aluminum foil, and dried under vacuum at 120° C. for 12 hours to obtain a positive electrode sheet.

[0057] 2. Weigh 0.7g of hard carbon negative electrode material, weigh 0.2g of acetylene black as conductive carbon and 0.1g of polyvinylidene fluoride as binder respectively according to the mass ratio of 7:2:1, and disperse the above three materials in N-methylpyrrolidone solvent, mixed evenly, coated on copper foil, dried under vacuum condition at 120° C. for 12 hours, to obtain negative electrode sheet.

[0058] 3. Place in the CR2032 button battery in the order of the positive pole p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com