Automatic bearing assembly machine and bearing installation method

A technology for bearing mounting seats and assembly machines, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of long installation hours, time-consuming and laborious, and low assembly efficiency, and achieve short installation hours, reduce labor costs, and facilitate assembly high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

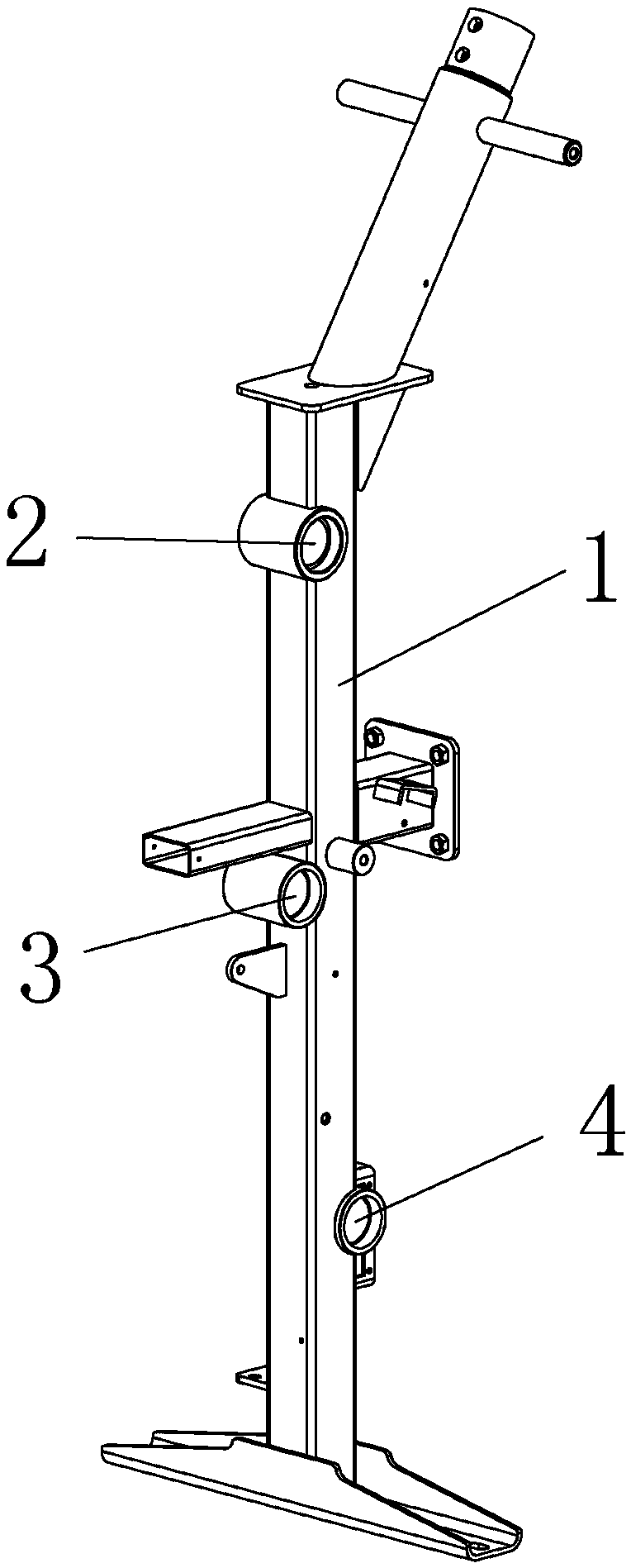

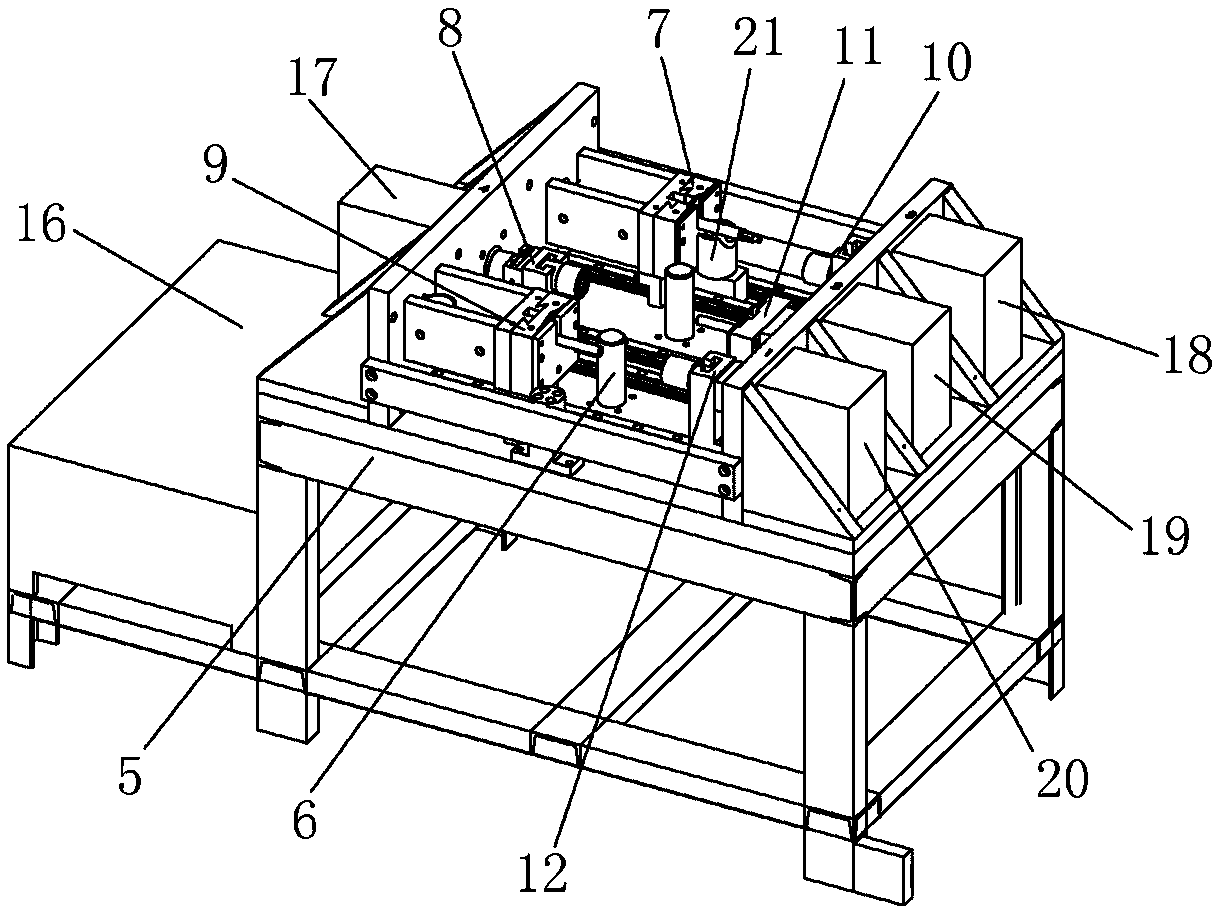

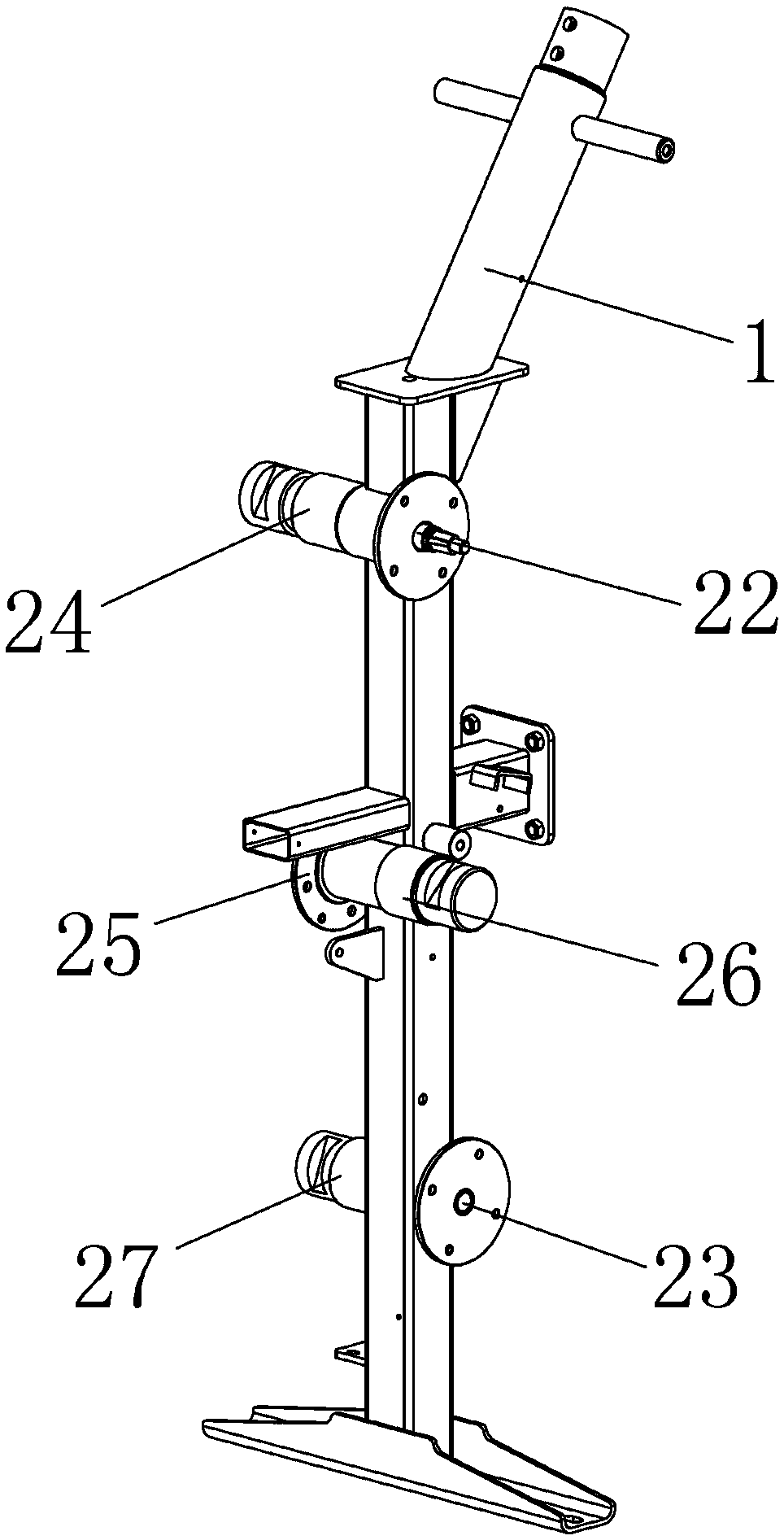

[0016] refer to Figure 2 to Figure 4 , an automatic bearing assembly machine, including a square frame-shaped assembly frame 5, the middle part of the assembly frame 5 is provided with an oil pressure support seat 6 that can move up and down and an immovable main frame positioning column 21, the assembly frame 5 One inner side of the assembly frame 5 is installed with the first rotating shaft mounting seat 7, the first bearing mounting seat 8 and the second rotating shaft mounting seat 9 sequentially from front to back, and the second bearing mounting seat 10, the third rotating shaft mounting seat 9 are installed on the other inner side of the assembly frame 5 Rotary shaft mounting seat 11 and the third bearing mounting seat 12, the axis of the first rotating shaft mounting seat 7 is on the same axis as the axis of the second bearing mounting seat 10, the axis of the first bearing mounting seat 8 is aligned with the axis of the second bearing mounting seat 10 The axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com