Dust suction and removal device in tile cutting machine

A technology for vacuuming and cutting machines, applied in stone processing tools, working accessories, manufacturing tools, etc., can solve problems such as environmental damage, threats to the health of operators, and lack of dust removal devices, so as to protect the working environment and suppress dust Diffuse and ensure the effect of good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

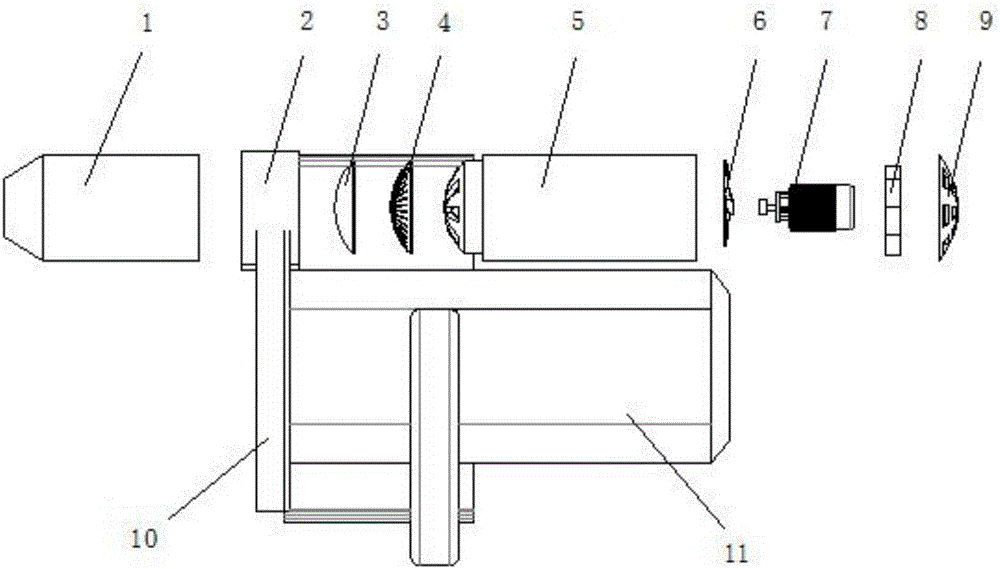

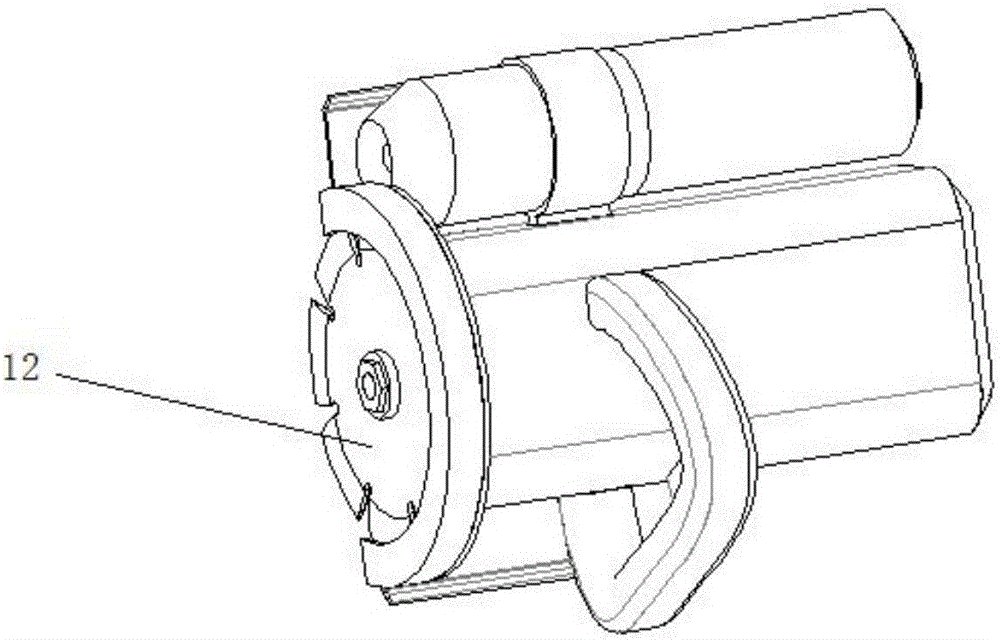

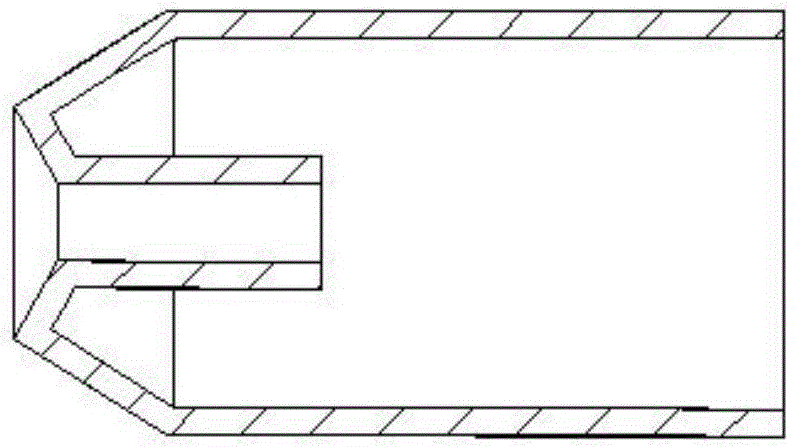

[0013] like figure 1 As shown in the figure, the tile cutting machine shown is equipped with a dust-absorbing and dust-removing device, and the cutting machine 11 is provided with a protective cover 10 and a cutting blade 12. There is a motor 7 inside, a fan blade 6 is provided on the motor 7, a filter screen 4 for protecting the motor 7 and the fan blade 6 is provided at the end of the body 5 and the casing 1, and the filter screen 4 is placed in the casing 1 , the filter screen 4 is provided with a filter paper 3 for blocking dust, the filter paper 3 is close to one end of the shell 1, and the other end of the shell 1 is provided with a suction port, the suction port is tangent to the end face of the cutting machine blade guard 10, inside the shell 1 A dust collection chamber is provided, and a wire is provided on the fuselage 5 to be connected with an external power supply.

[0014] When in use, turn on the power, and then press the switch on the handle of the cutting mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com