Air curtain powder capturing type metal surface wire drawing treatment process

A metal surface and processing technology, which is applied in the field of air curtain powder-catching metal surface wire drawing processing technology to avoid potential safety hazards, reduce the flying of metal powder and improve adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

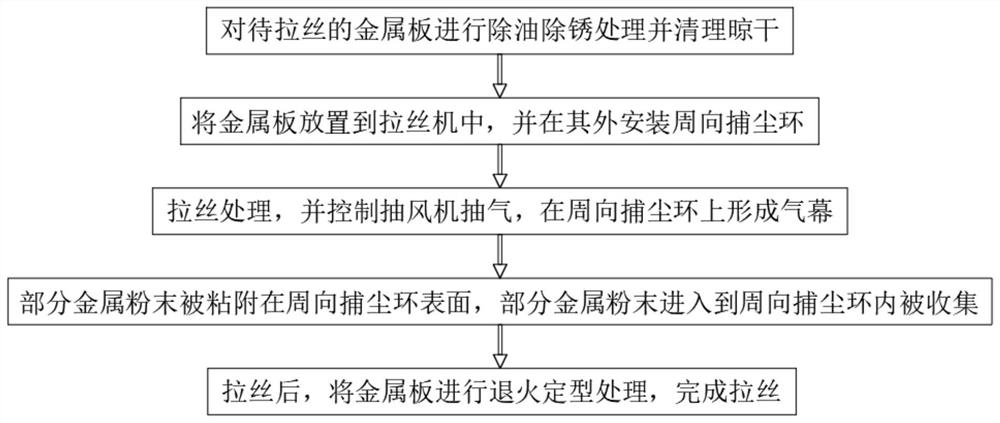

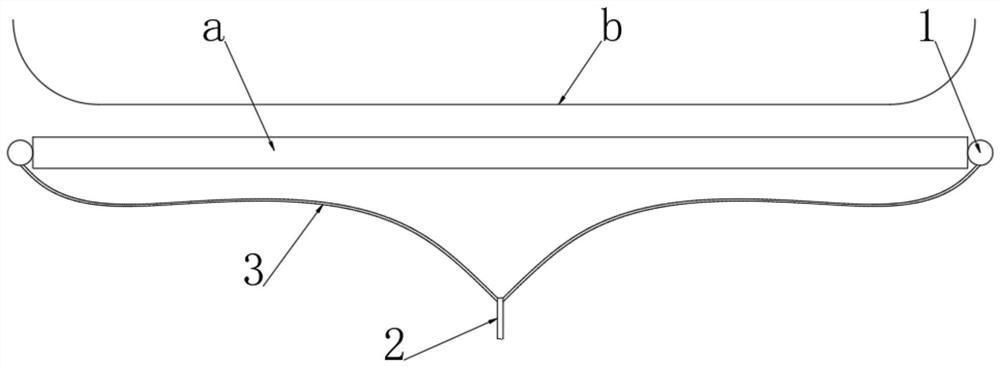

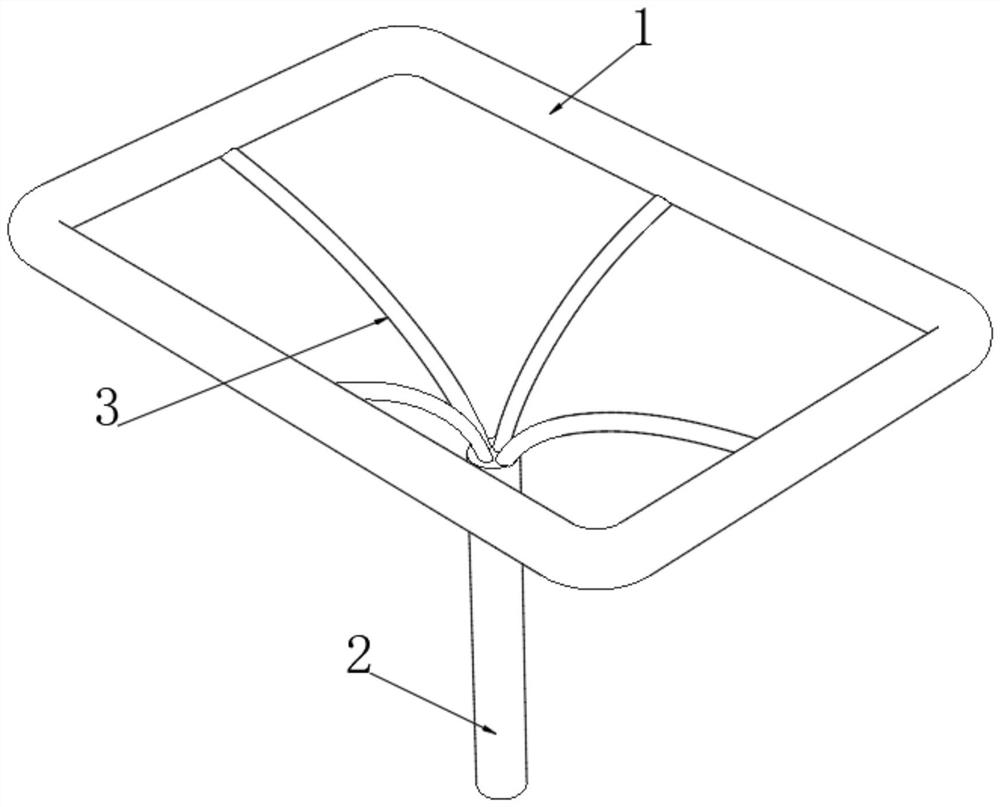

[0047] see Figure 1-2 , in the figure, a represents the metal plate, and b represents the drawing tape, an air curtain powder-catching metal surface drawing treatment process, including the following steps:

[0048] S1. Carry out degreasing and derusting treatment on the metal plate to be drawn, and finally clean and dry;

[0049] S2. Place the dried metal plate in the wire drawing machine, and install a circumferential dust-catching ring on the outer end of the metal plate;

[0050] S3. Carry out wire drawing treatment on the metal plate in the wire drawing machine, and at the same time draw air through the exhaust fan, so that the outer end of the circumferential dust collection ring forms an air curtain around the metal plate;

[0051] S4. After the metal powder produced by wire drawing overflows from between the wire drawing tape and the metal plate, it is intercepted by the air curtain and moves towards the circumferential dust collection ring with the air curtain. Part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com