A suction and exhaust mechanism for producing soft capsules covered with hard capsules

A soft capsule, suction and exhaust technology, used in capsule delivery, pharmaceutical formulations, drug delivery and other directions, can solve the problems of increased pump operations, low production efficiency, large losses, etc., to reduce unnecessary losses, improve production efficiency, High air tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

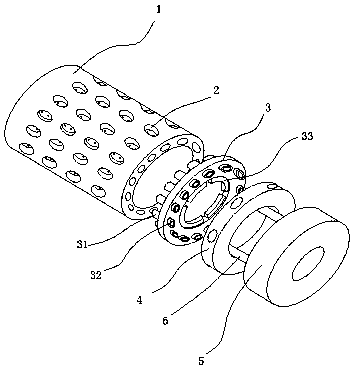

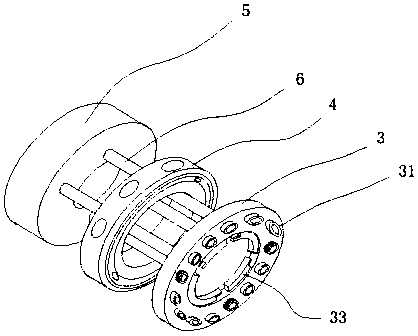

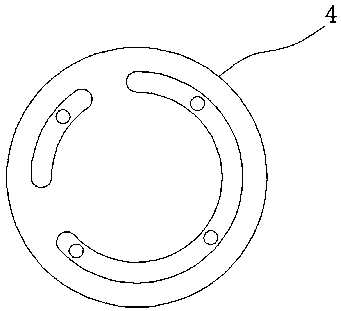

[0020] The present invention proposes a suction and exhaust mechanism for producing soft capsules covered with hard capsules, comprising a capsule mold 1, one side of the capsule mold 1 is provided with a connecting ring 3, and an arc is installed on the inner wall of the connecting ring 3 shaped block 33, bayonet joints are formed at intervals between the two arc-shaped blocks 33, the side of the connecting ring 3 away from the medicine bag mold 1 is provided with an air inlet ring 4, and the edge of the connecting ring 3 is provided with an air inlet, and the air inlet One side of the mouth is connected with a connecting pipe 32, and the other side of the air inlet is provided with an air inlet pipe 31, and the end of the air inlet pipe 31 away from the connecting ring 3 is inserted in the air inlet channel, and the side of the air inlet pipe 31 is sleeved with a sealing The side of the air intake ring 4 near the connection ring 3 is provided with an air intake groove and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com