Civil aircraft undercarriage assembling and disassembling vehicle suitable for multiple aircraft types

A technology of aircraft landing gear and landing gear, which is applied in aircraft assembly, aircraft maintenance and other directions to achieve the effect of easy assembly and control, and improved operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

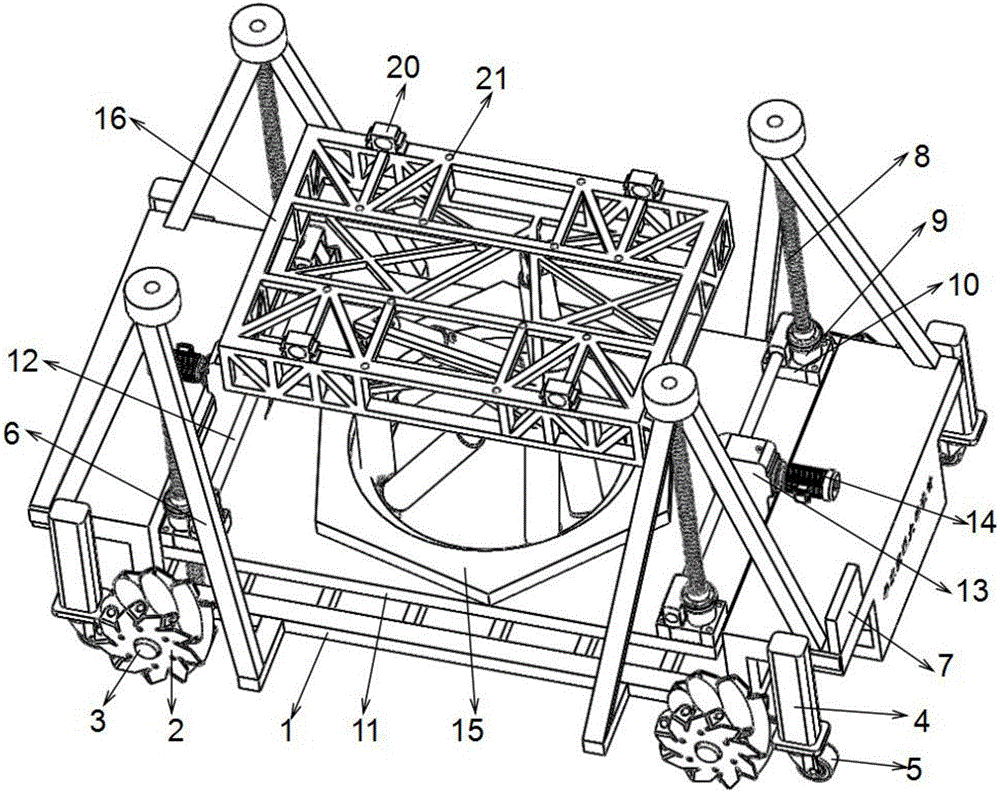

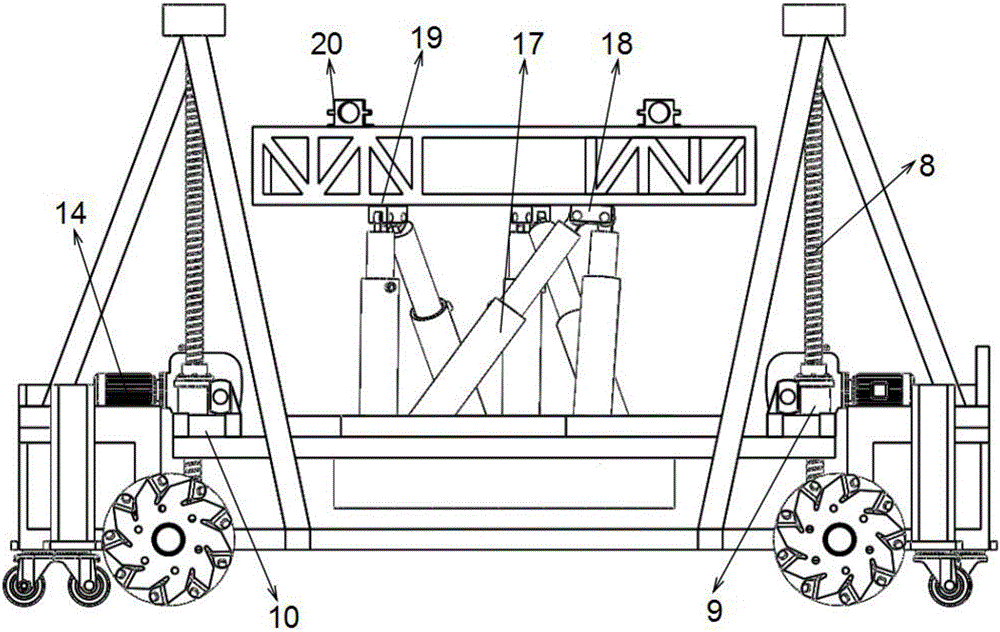

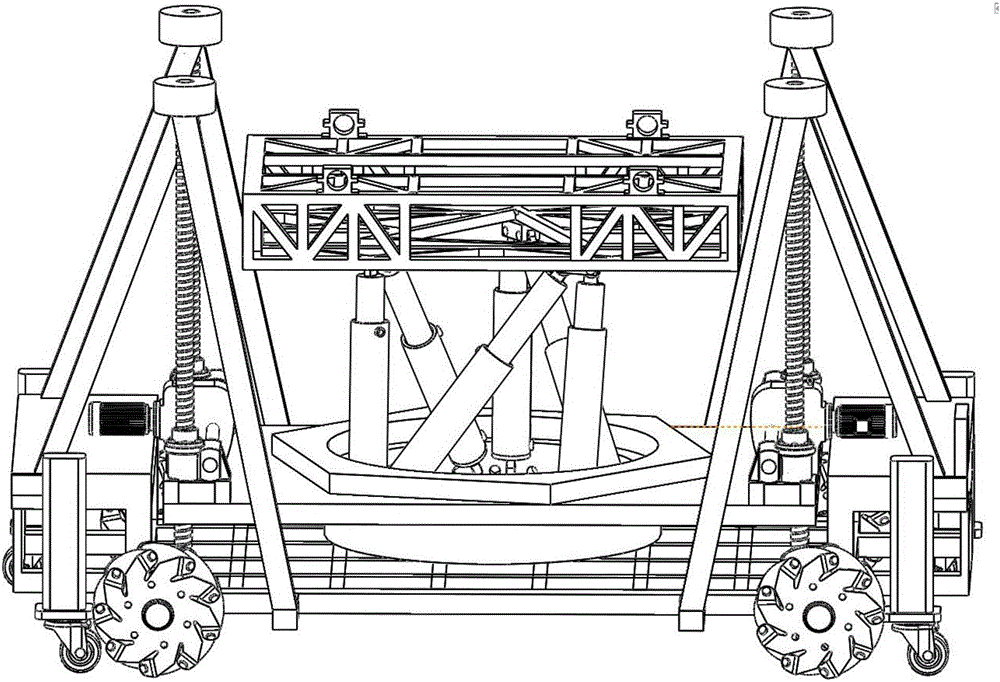

[0013] A multi-type civil aviation aircraft landing gear dismantling vehicle is characterized in that it includes five main parts: a mobile chassis, a ball screw lifting device, a six-degree-of-freedom parallel fine-tuning mechanism, a force sensing device, and a porous position detachable support.

[0014] When a certain aircraft needs to disassemble the landing gear, the control system [7] controls the four Mecanum wheel mechanisms [2] of the aircraft landing gear dismantling vehicle to move the dismantling vehicle under the pre-fixed aircraft landing gear, and the Mecanum The wheel mechanism [2] is connected with the chassis steel frame [1] through the connecting shaft [3], and is to form the mechanical part of the omnidirectional mobile chassis, and the height of the dismounting vehicle will be lower than the actual installation position of the landing gear. The bracket [6] and the chassis steel frame [1] are used to support the ball screw [8], and then the ball screw lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com