A waste rubber regeneration device and regeneration equipment with in-situ precise heating

A regenerative device and heating device technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, plastic recycling, etc., can solve the problems of long cleaning cycle, energy waste, equipment damage, etc., to reduce labor intensity and avoid material sticking Material and blockage, improve the effect of heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

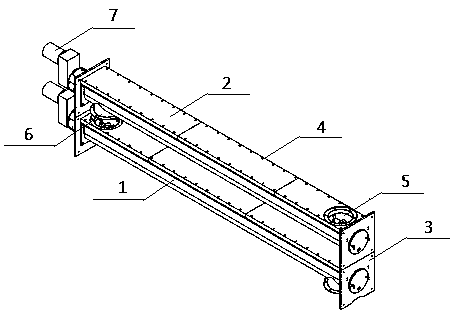

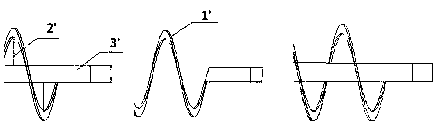

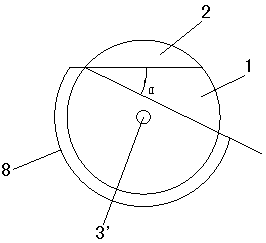

[0030] A waste rubber regeneration device with in-situ precise heating, including a detachable barrel composed of a barrel body 1 and a top cover 2, the barrel body 1 and the top cover 2 are fastened by a fixing screw 4, and the barrel is passed through a positioning bolt Fixed on the supporting baffles 3 on both sides; the waste rubber recycling device also includes a flexible conveying screw composed of flexible blades 1' and supporting rods 2' or a central shaft 3'; the flexible conveying screw is installed along the center of the barrel body 1 . The barrel body 1 has a material inlet 5 and a material outlet 6, and both the material inlet 5 and the material outlet 6 are rigidly connected to ensure the airtightness of the device.

[0031] One end of the heating device is set at ≤ 4 / 5 of the barrel height, especially, one end of the heating device is set outside the barrel body 1 below the top cover 2, or the barrel body 1 below the central axis 3' of the flexible conveying s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com