Mesh cloth treated by corona

A technology of corona treatment and mesh cloth, which is applied in the field of mesh cloth, can solve the problems of poor printing effect and achieve better effect, good printing effect and good adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described below.

[0015] The corona-treated mesh cloth of this embodiment is made of polyester material, and the mesh is arranged on the electrode frame for corona treatment on the front and back sides. The high-frequency AC voltage range of corona treatment is 4000-6000V / m 2 , The range of corona treatment speed is 15-25m / min.

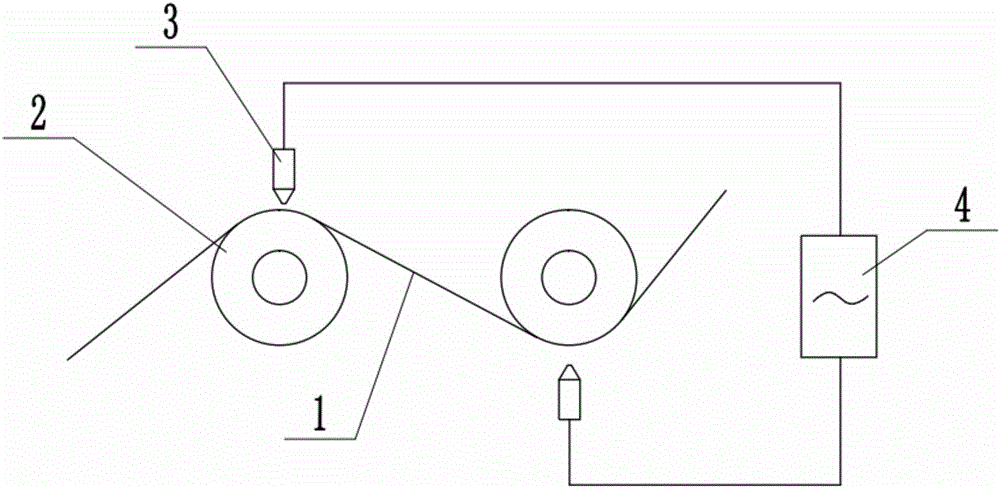

[0016] Such as figure 1 As shown, the polyester mesh 1 is wound on two side-by-side guide rollers 2 , above or below the guide rollers 2 there is an electrode rod 3 mounted on an electrode frame, and the electrode rod 3 is connected to a high-frequency generator 4 .

[0017] After corona treatment, the molecular structure of the mesh surface is rearranged to produce more polar parts, which is conducive to the attachment of foreign objects. In order for the photosensitive emulsion to adhere well to the surface of the mesh, the dyne value of the surface energy of the front and back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com