Asphalt mixture mineral aggregate gradation composition design method using internal friction angle as design index

A technology of asphalt mixture and design index, which is applied in the field of cohesive pavement, roads, buildings, etc., can solve the problem of not being able to maximize the excellent performance of the dense structure of the skeleton, at least failing to achieve a stable skeleton structure, and affecting the stability of the skeleton structure To reduce the possibility of shear flow deformation, reduce rutting and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

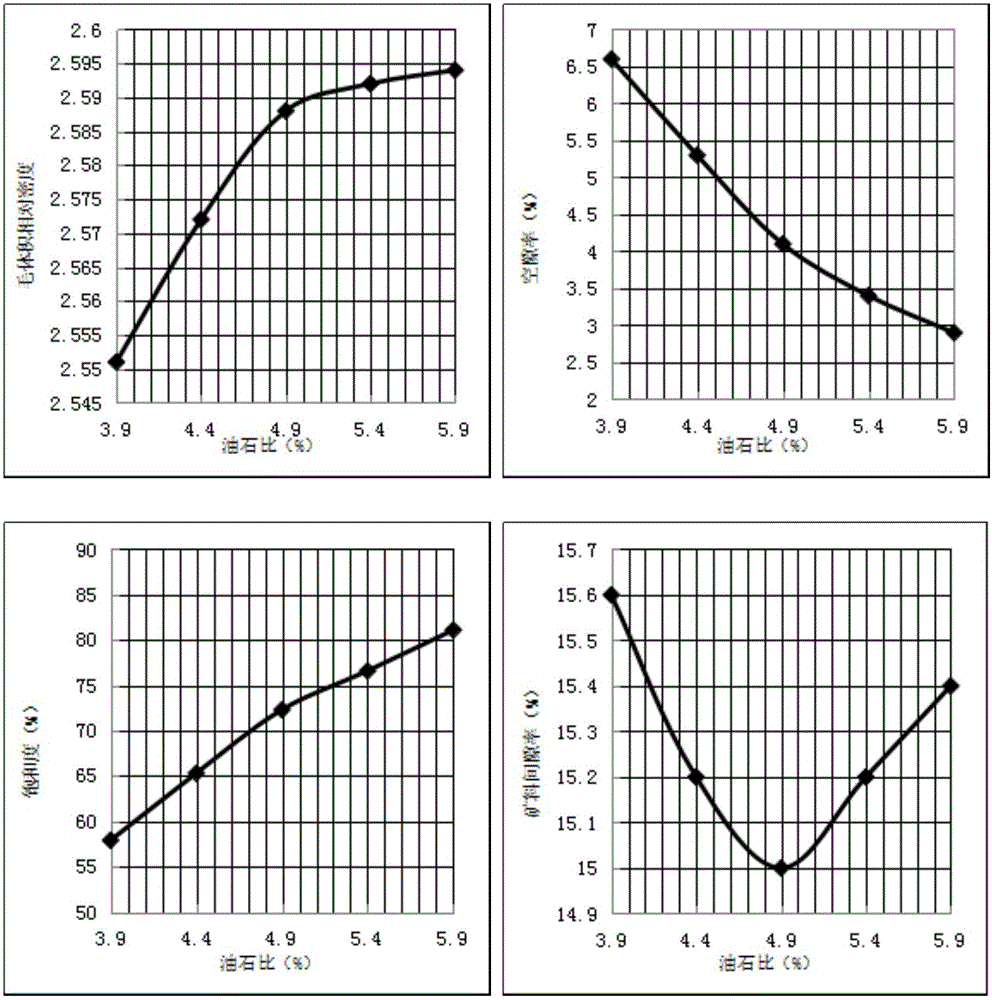

[0036] Taking AC-20 modified asphalt mixture as an example in the surface layer of asphalt pavement, the specific implementation method is as follows:

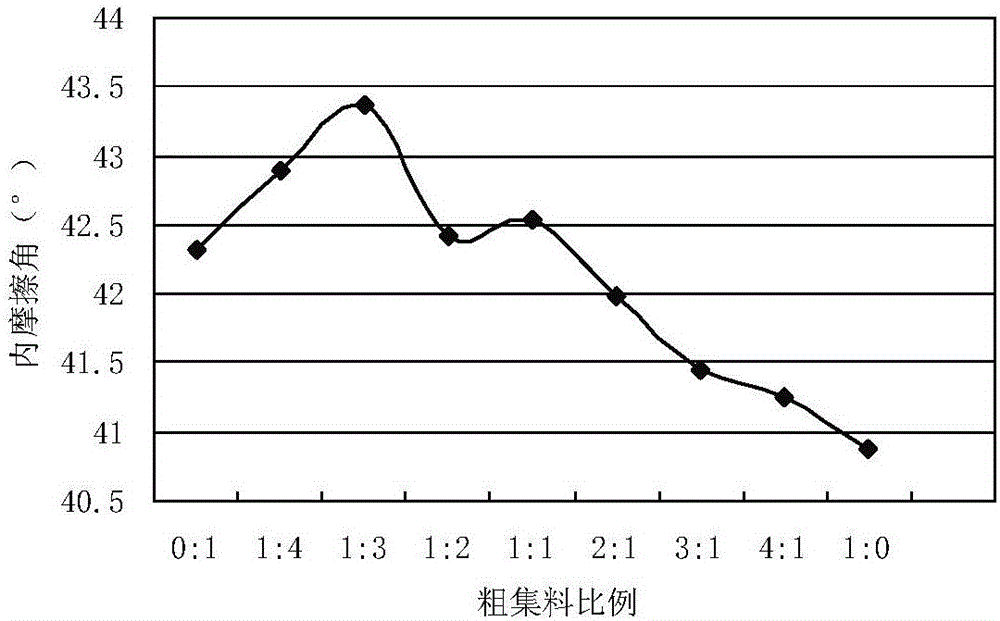

[0037] (1) Carry out the first-level filling test of coarse aggregates, the aggregates of 19-26.5mm and 16-19mm are mixed at 0:1, 1:4, 1:3, 1:2, 1:1, 2:1, The nine ratios of 3:1, 4:1, and 1:0 are mixed evenly, and a total weight of 20kg is taken for each ratio to conduct a shear test, and the internal friction angle of the mineral material is calculated at each ratio. The test results are as follows figure 1 As shown, when the composition ratio is 1:3, the internal friction angle is the largest, and the shear resistance is the best;

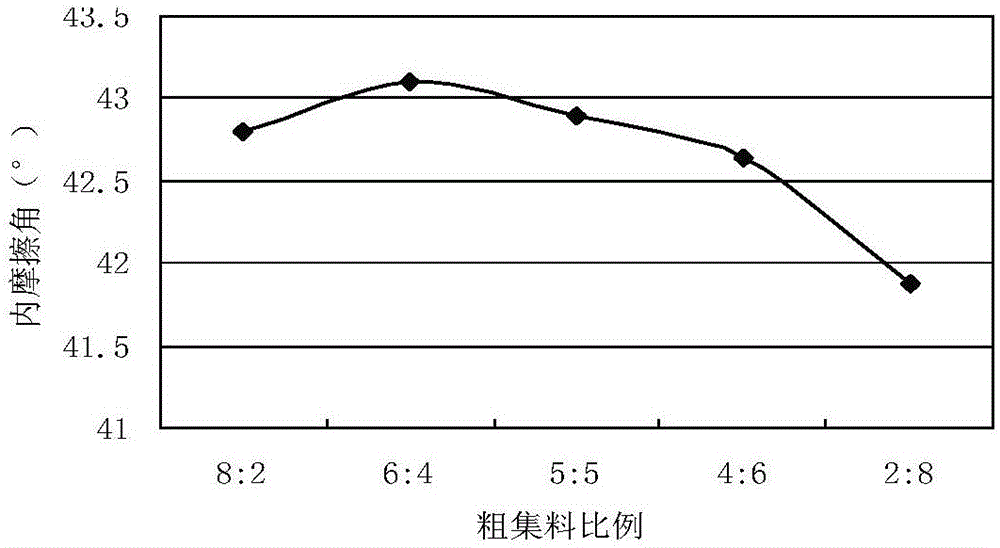

[0038](2) On the basis of the skeleton formed by the optimal filling ratio of the first level, the second level filling is carried out, and the 16-26.5mm and 13.2-16mm aggregates are 4:1, 3:2, 1:1, 2:3, The five ratios of 1:4 are mixed evenly, and the shear test is carried out in the same way, a...

Embodiment 2

[0055] Taking AC-13 modified asphalt mixture for the surface layer of asphalt pavement as an example, the specific implementation method is as follows:

[0056] (1) Carry out the first-level filling test of coarse aggregates, the aggregates of 13.2-16mm and 9.5-13.2mm are mixed at 0:1, 1:4, 1:3, 1:2, 1:1, 2:1, The eight ratios of 3:1 and 4:1 are mixed evenly, and the total weight of each ratio is 20kg for shearing test, and the internal friction angle of the mineral material is calculated at each ratio. The test results are as follows Image 6 As shown, when the composition ratio is 1:3, the internal friction angle is the largest, and the shear resistance is the best;

[0057] (2) On the basis of the skeleton formed by the optimal filling ratio of the first level, the second level filling is carried out, and the 9.5-13.2mm and 4.75-9.5mm aggregates are 4:1, 3:2, 1:1, 2:3 , 1:4 and five kinds of ratios are mixed evenly, and the shear test is carried out in the same way, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com