Design method of metal damper

A metal damper and design method technology, applied in building components, building types, earthquake resistance, etc., can solve the problems of weak deformation ability, unsatisfactory damping effect, and low utilization rate of damper materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

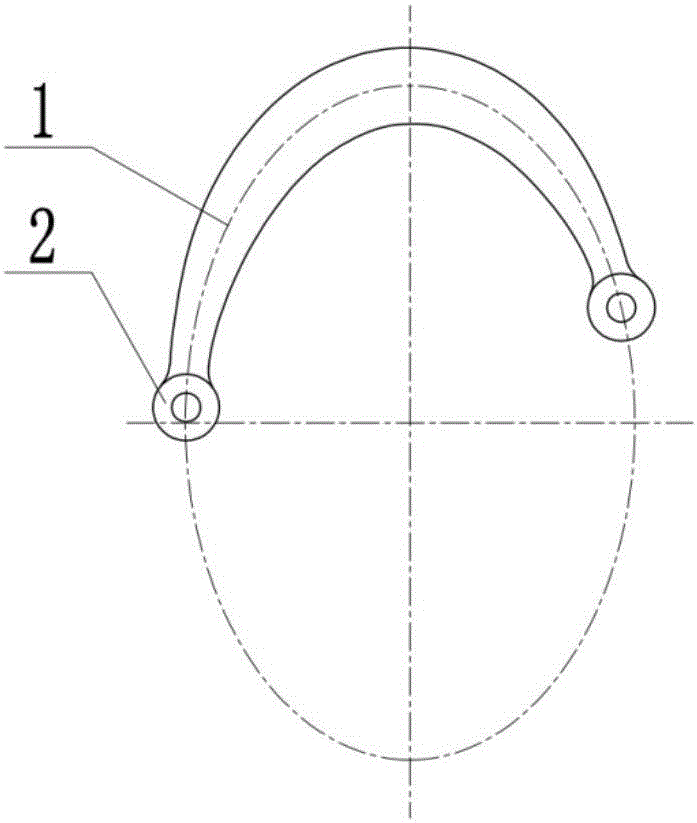

[0051] Implementation Mode 1: Basic shape and design method of asymmetric metal damper

[0052] An asymmetric metal damper (such as figure 1 ), consisting of a C-shaped metal plate whose centerline is taken from an asymmetrical elliptical arc. The equal rigidity design method is used to make the maximum normal stress of each section equal and reach the yield stress of the material. When the damper undergoes large deformation, each section can enter the plastic working state at the same time, producing a damping effect and achieving the purpose of energy consumption. The equal rigidity design is adopted to ensure the uniformity of the overall deformation when the damper is compressed or stretched, and avoid local accumulation of strain, which will lead to component damage and failure.

[0053] During the design process of the damper, the center line parameters and the arc segment taken can be determined according to the installation requirements, and the remaining technical pa...

Embodiment approach 2

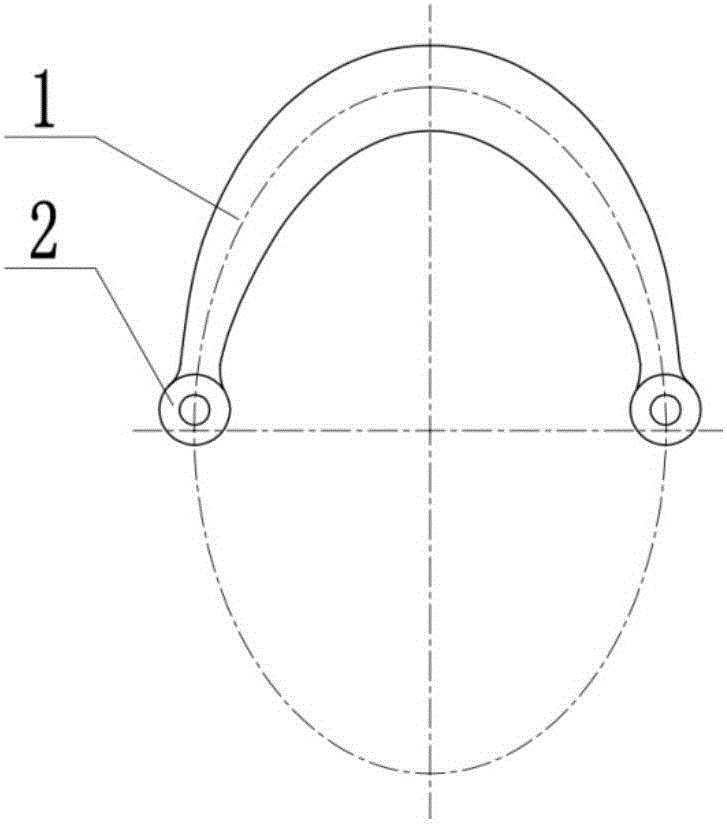

[0073] Implementation Mode 2: Basic Shape and Design Method of Symmetrical Metal Damper

[0074] A symmetrical metal damper (such as figure 2 ), whose centerline is taken from a symmetrical elliptical arc. Its design method is consistent with Embodiment 1, and it is a special application example of the asymmetric metal damper described in Embodiment 1.

[0075] Symmetrical and asymmetrical dampers have certain differences in external dimensions, damping characteristic curves and other characteristics, and can be selected and designed according to specific application requirements.

Embodiment approach 3

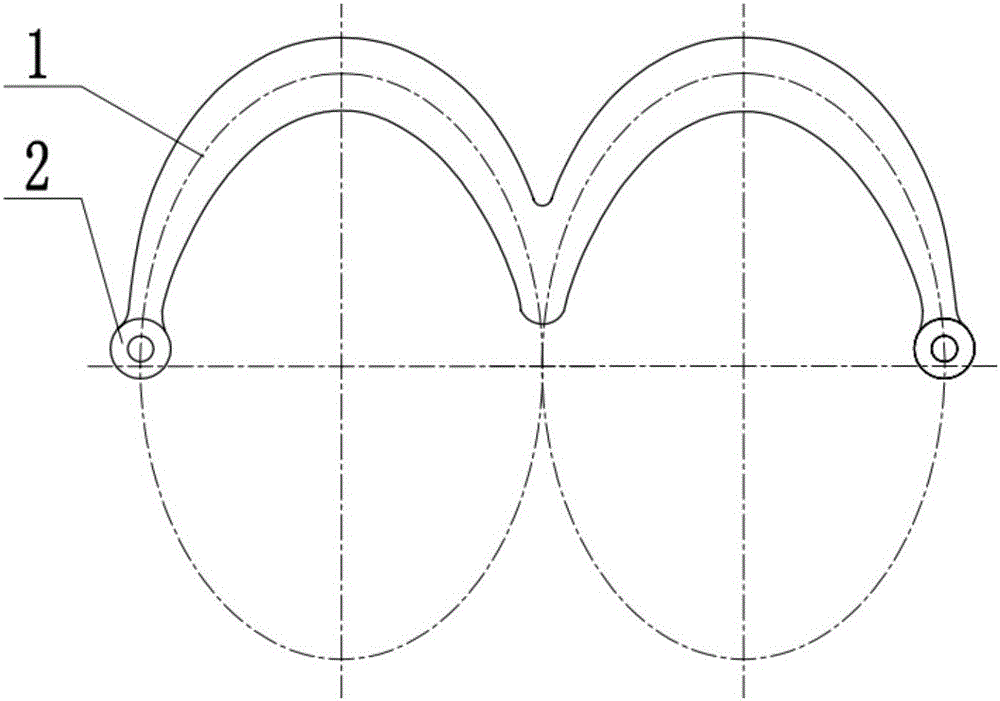

[0076] Implementation mode three: E-type equal rigid arm metal damper

[0077] Connect two symmetrical (or asymmetrical) metal dampers in series to form an E-shaped structure, such as image 3 , Figure 4 shown. The E-type damper can increase the damping displacement to twice that of the single damper when the damping force remains unchanged. Its design calculation method is similar to that of the single damper. According to different installation methods, it can be divided into Intermediate mounting holes (such as Figure 4 ) and without intermediate mounting holes (such as image 3 ) in two forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com