Water shut-off and profile control method for oil-water well

A water plugging profile control, oil-water well technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of loss of plugging effect, complicated site reality, and failure to plug, so as to reduce pollution, The effect of large maneuvering space and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

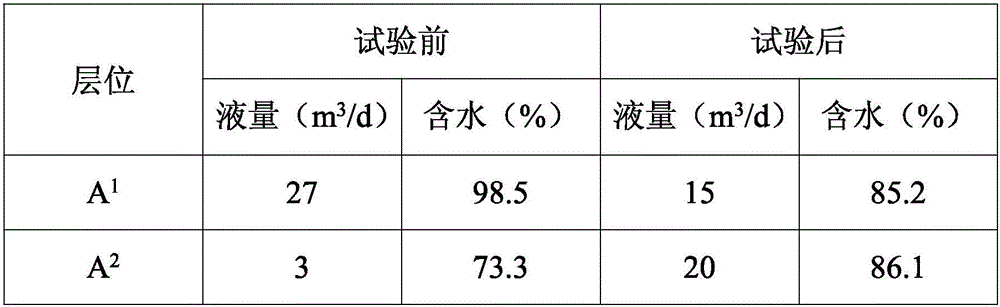

Embodiment 1

[0025] Test well A 32 General situation: The oil layer temperature of the oil well is 60℃, the oil layer pressure is 12.5MPa, and the permeability is 700×10 -3 μm 2 , Formation water salinity 5682mg / L, porosity 32.3%, crude oil viscosity 785mPa·s, oil-water well spacing 200m, oil well daily production volume is 30m 3 / d, daily oil production is 1.2t / d, water content is 96.0%; production horizon is 2 layers, numbered A 1 , A 2 , The thickness of the oil layer is 5m, 4m, and the permeability is 1500×10 -3 μm 2 , 200×10 -3 μm 2 , The liquid production profile test shows that A 1 Layer liquid production is 27m 3 / d, A 2 Layer liquid production is 3m 3 / d, where A 1 The water content of the layer is above 98.2%. Using the method of the present invention to perform on-site application of oil well water shutoff in this well, the specific steps are as follows:

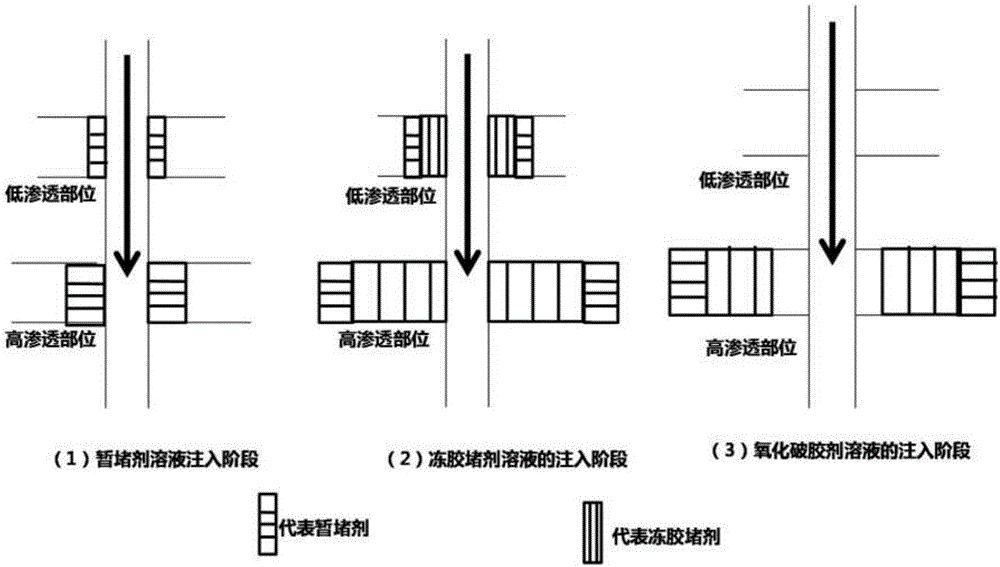

[0026] (1) Injection stage of temporary plugging agent solution

[0027] First, prepare the temporary plugging agent solution at t...

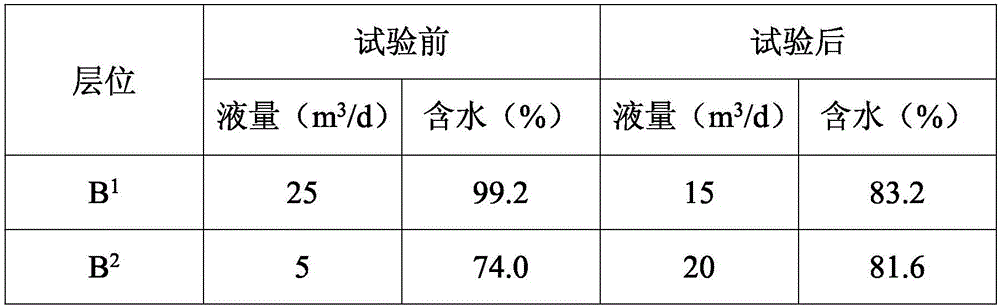

Embodiment 2

[0040] Test well B 21 General situation: the oil layer temperature of the oil well is 76℃, the oil layer pressure is 13.7MPa, and the permeability is 850×10 -3 μm 2 , Formation water salinity is 15685mg / L, porosity is 32.3%, crude oil viscosity is 1568mPa·s, oil-water well spacing is 200m, and oil well’s daily fluid production is 30m 3 / d, daily oil production is 1.5t / d, water content is 95.0%; production horizon is 2 layers, numbered B 1 , B 2 , The thickness of the oil layer is 4m, 6m, and the permeability is 1200×10 -3 μm 2 , 150×10 -3 μm 2 , The liquid production profile test shows that B 1 Layer liquid production is 25.0m 3 / d, B 2 Layer liquid production is 5.0m 3 / d, where B 1 The layer contains 99.2% water content. Using the method of the present invention to perform on-site application of oil well water shutoff in this well, the specific steps are as follows:

[0041] (1) Injection stage of temporary plugging agent solution

[0042] First in blocking well B 21 The temporary...

Embodiment 3

[0055] Test injection well C 42 General situation: formation temperature of water well is 50℃, water injection pressure is 5.2MPa, permeability is 850×10 -3 μm 2 , Water injection volume 100m 3 / d; The water injection horizon is 3 layers, numbered C 1 , C 2 , C 3 , The thickness is 5m, 3m, 6m respectively, the water absorption profile test shows that C 1 Layer water absorption is 10m 3 / d, C 2 Layer water absorption is 75m 3 / d, C 3 Layer water absorption is 25m 3 / d, where C 2 The layer water absorption accounted for 75.0% of the total water injection volume. Using the method of the present invention to perform on-site application of water well profile control in this well, the specific steps are as follows:

[0056] (1) Injection stage of temporary plugging agent solution

[0057] First in profile control well C 42 The temporary plugging agent solution is prepared at the well site; secondly, the prepared temporary plugging agent solution is injected into the profile control well C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com