Cold-extruding lock clamp for unmanned aerial vehicle and preparation method of cold-extruding lock clamp

A cold extrusion, unmanned aerial vehicle technology, applied in mechanical equipment, unmanned aerial vehicles, motor vehicles, etc., can solve the problems of unstable product quality, inability to guarantee interchangeability, difficult size uniformity, etc., to achieve product quality. Good quality stability, simple structure and good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

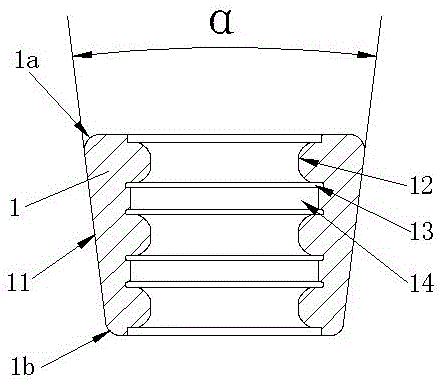

[0021] Such as figure 1 Shown is the structural representation of the present invention,

[0022] The reference signs therein are: opening angle α, lock clip clip 1, upper arc surface 1a, lower arc surface 1b, outer conical surface 11, raised arc 12, annular groove 13, spacer band 14.

[0023] Such as figure 1 as shown,

[0024] A cold extruded lock clip for drones, including two lock clip clips 1 with semicircular cross-sections that can be combined to form a ring structure, and the lock clip clip 1 is formed by cold extrusion of low-carbon alloy steel , the outer circumference of the lock clip clip 1 is cold extruded to form an outer conical surface 11 that is compatible with the inner conical surface of the valve spring seat, and there are three protrusions at intervals in the inner hole where the lock clip clip 1 is fixedly fitted with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Zhang jiao | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com