Transversely heated ice melting blade of wind turbine and the device and method of melting

A technology of wind power generators and generators, which is applied in the monitoring of wind power generators, wind power generators, wind power generators consistent with the wind direction, etc., and can solve problems affecting power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

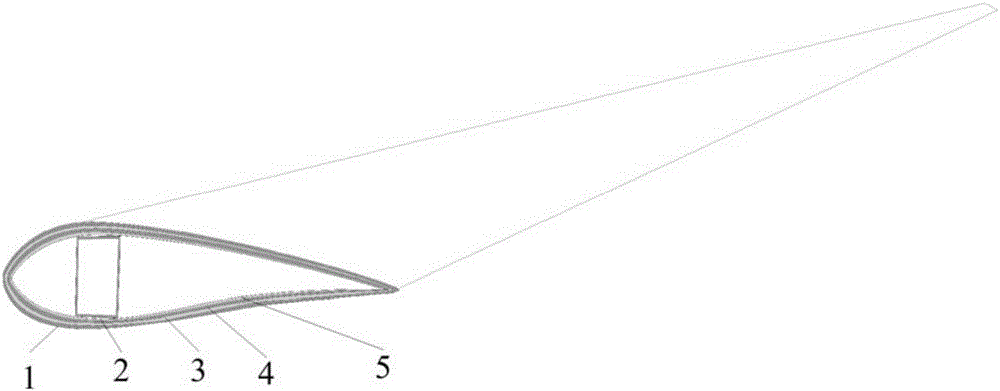

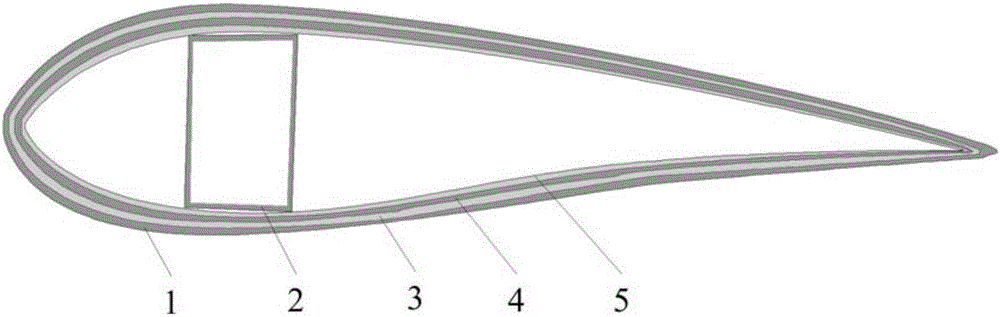

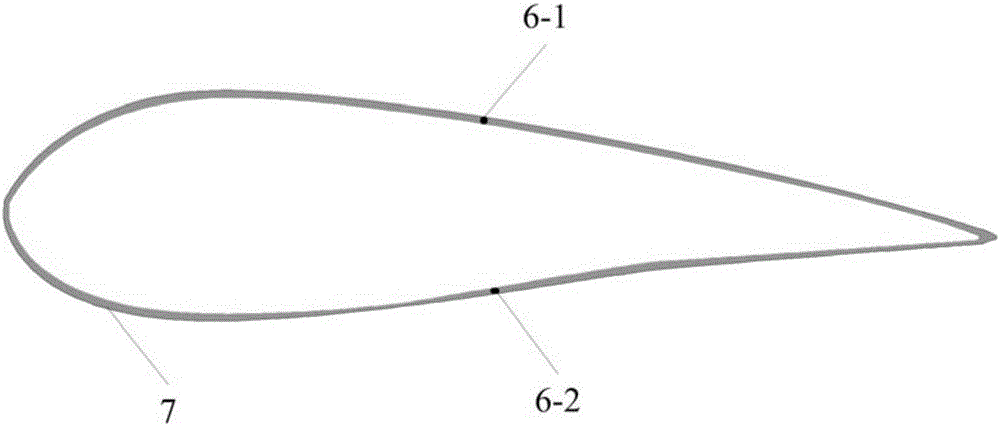

[0063] See attached figure 1 , 2 .

[0064] A conventional wind generator blade is composed of a blade main beam 2 and a blade skin 5, and the blade main beam and blade skin 5 of the present invention are designed according to a conventional blade design method. In the present invention, a layer of heating layer 4 is provided outside the blade skin 5 to completely wrap the blade skin 5, an insulating layer 3 is arranged outside the heating layer 4 to completely wrap the heating layer 4, and a lightning protection layer 1 is arranged outside the insulating layer 3 to completely wrap it. Insulation layer 3, the lightning protection layer is connected with the lightning ground wire. The insulating layer completely wraps the heating layer, and the insulating layer adopts insulating material. The insulating material of this embodiment adopts glass fiber. The lightning protection layer is a metal mesh or metal sheet that completely wraps the insulating layer. The lightning prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com