Device and method for automatic flow checking and calibration of on-line particulate matter analyzer

A technology for automatic inspection and calibration of devices, applied in testing/calibrating devices, measuring devices, testing/calibrating volume flow, etc., to achieve high accuracy, easy design, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

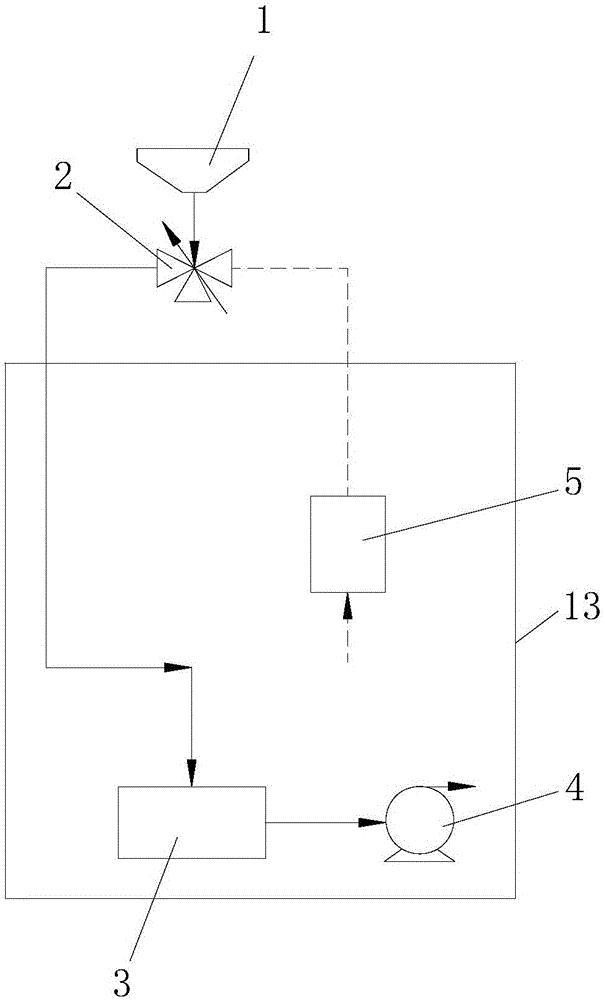

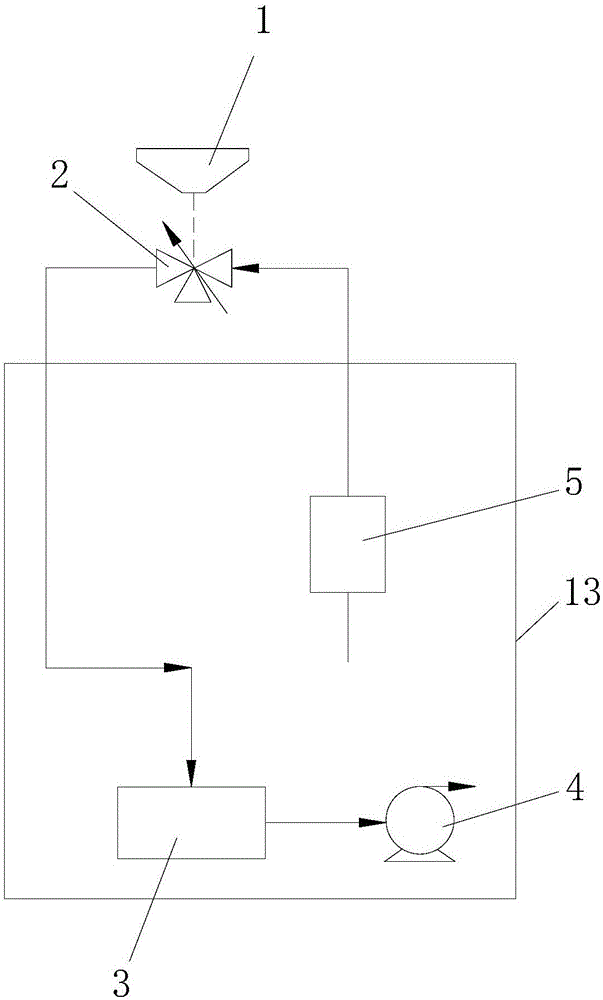

[0045] An online particulate matter analyzer flow automatic inspection and calibration device, including a cyclone cutter 1, a connection switch 2, a particle analyzer 3, an air pump 4, a standard flow meter 5 and a control terminal, a cyclone cutter, and a particle analyzer and the standard flowmeter are respectively connected to the connection switcher, and the particle analyzer is connected to the suction pump;

[0046] The control terminal is connected to the connection switcher, and is used to control the connection between the particle analyzer and the cyclone cutter or the standard flowmeter; preferably, the control terminal sends a control command to the connection switcher, so that the connection switcher controls the connection with the cyclone cutter The cutter is connected or connected to a standard flow meter.

[0047] The standard flow meter is connected with the control terminal for sending the instantaneous flow value to the control terminal;

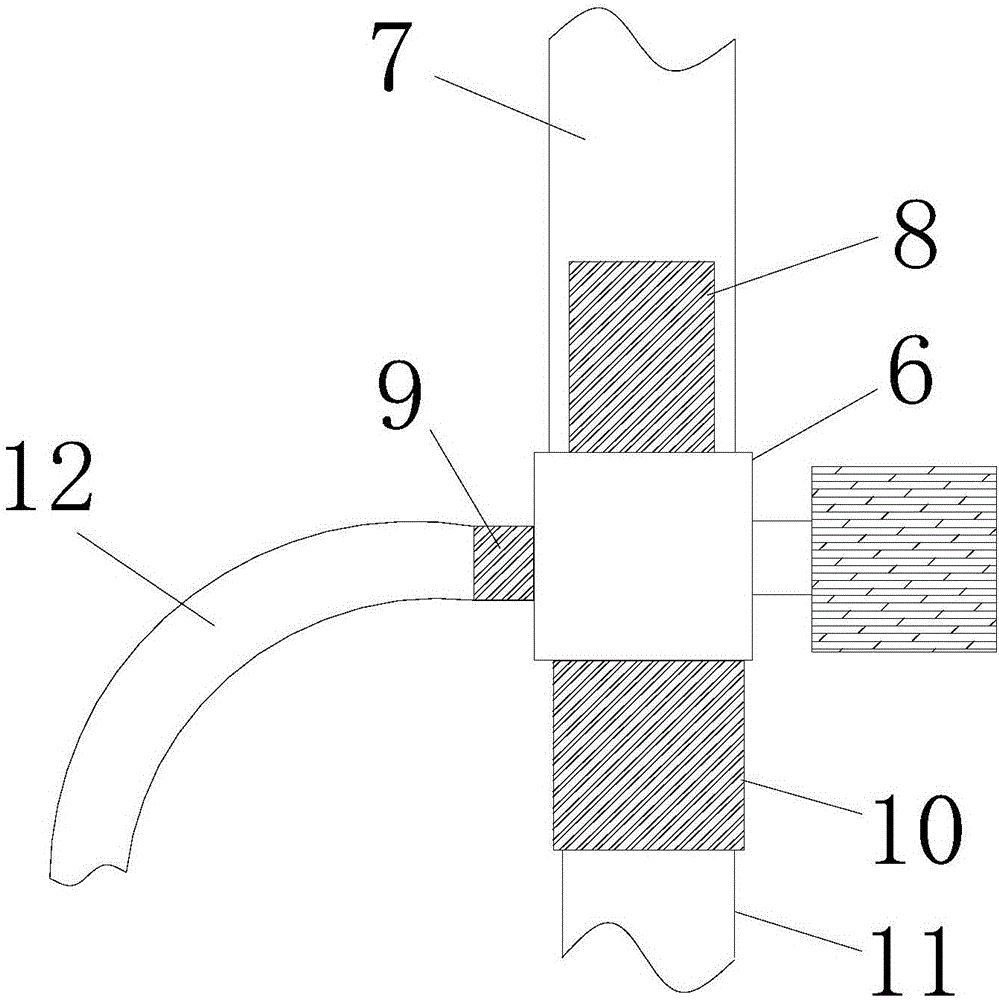

[0048] The part...

Embodiment 2

[0057] A method for automatic checking and calibrating the flow rate of an online particle analyzer, comprising the following steps:

[0058] Sampling and analysis: connect the switcher to connect the particle analyzer to the cyclone cutter, start the suction pump, and the ambient air is sucked in from the cyclone cutter, and enters the particle analyzer for analysis after connecting the switcher, and finally passes through the suction pump pull out

[0059] When checking the flow rate, the connection switcher cuts off the connection between the particle analyzer and the cyclone cutter and connects the standard flowmeter to the particle analyzer. The air is sucked in from the standard flowmeter and enters the particle analysis through the connection switcher. The real-time instantaneous flow value is obtained through the standard flowmeter. When flow calibration is required, the control terminal compares the instantaneous flow value detected by the standard flowmeter with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com