Method for forming cutter machining tracks on NURBS combined curved surface

A technology of processing trajectory and processing direction, which is applied in the field of tool processing trajectory generation on NURBS composite surfaces, can solve the problems of affecting the appearance and processing quality of the workpiece, not being able to process, and the single topology of the trajectory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

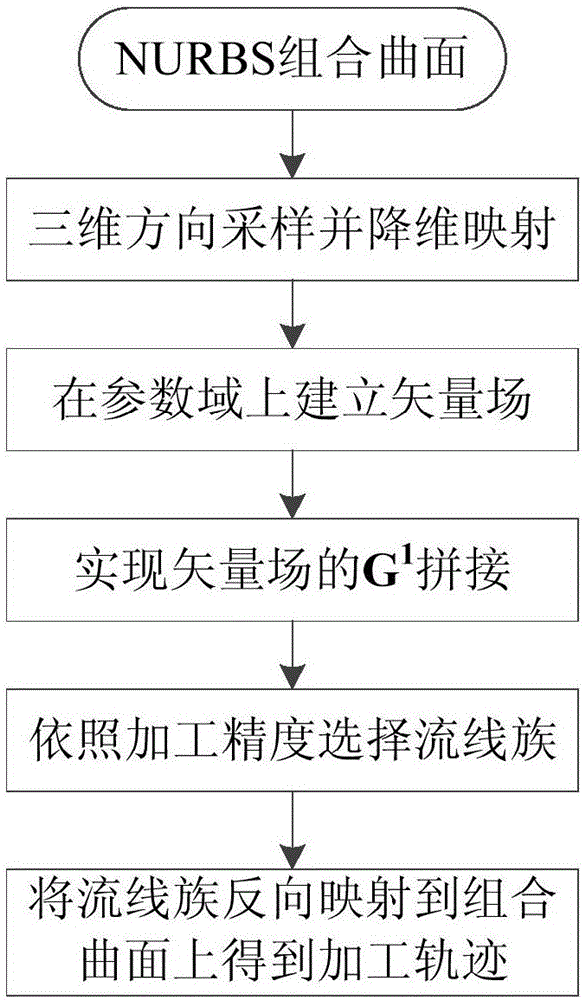

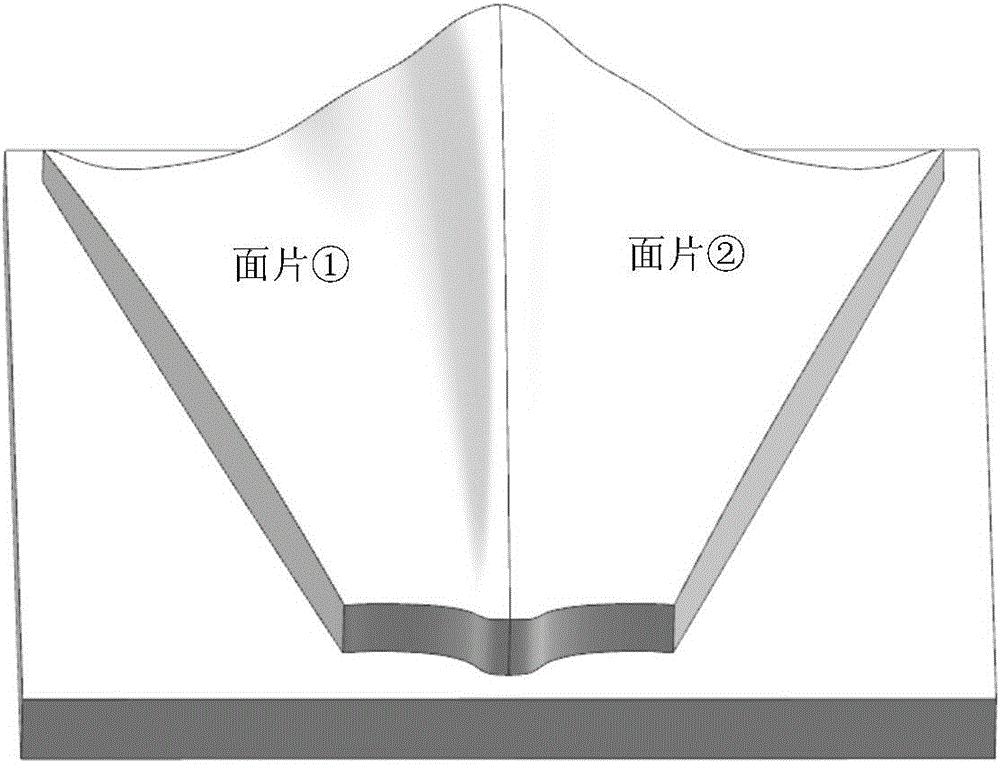

[0043] The flow chart of a method for generating tool machining paths on NURBS composite surfaces is as follows: figure 1 shown. In order to highlight the characteristics of the present invention to generate the tool path, here with C 1 Take the continuous two-face NURBS compound surface as an example (see figure 2 ), with reference to the accompanying drawings and implementation steps the specific implementation process of the present invention is described in detail:

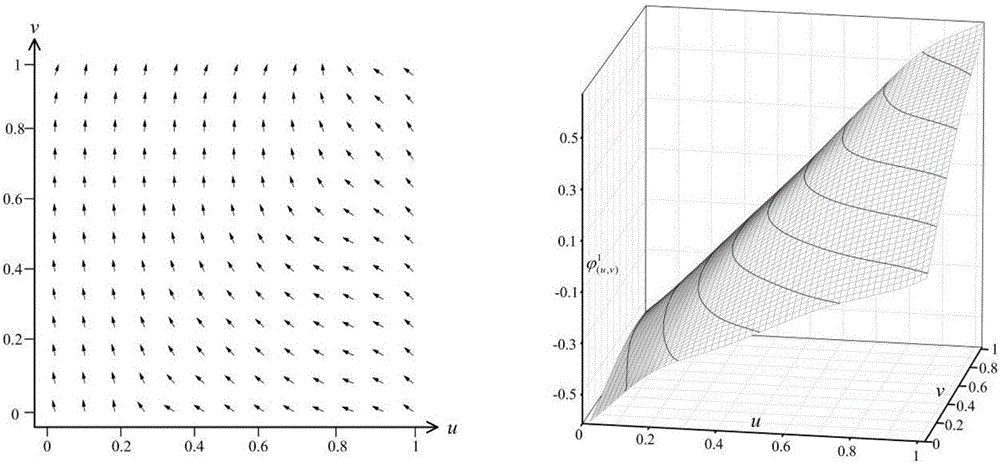

[0044] (a) Carry out grid division for each patch, and the optimal cutting direction at each grid point is selected as the maximum bandwidth direction at that point, and the expression of this direction in the parameter domain is as follows:

[0045] a = cos - e 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com