Open structure, manufacturing method thereof and interconnect structure

A technology with an opening structure and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of reduced process margin, ineffective connection between contact windows and pads, etc., to improve the process margin. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

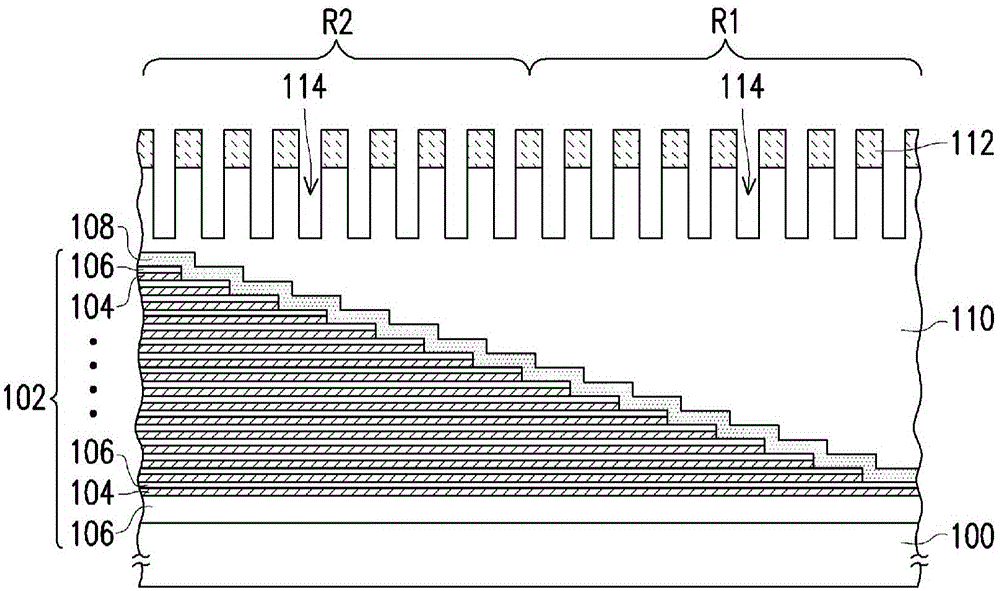

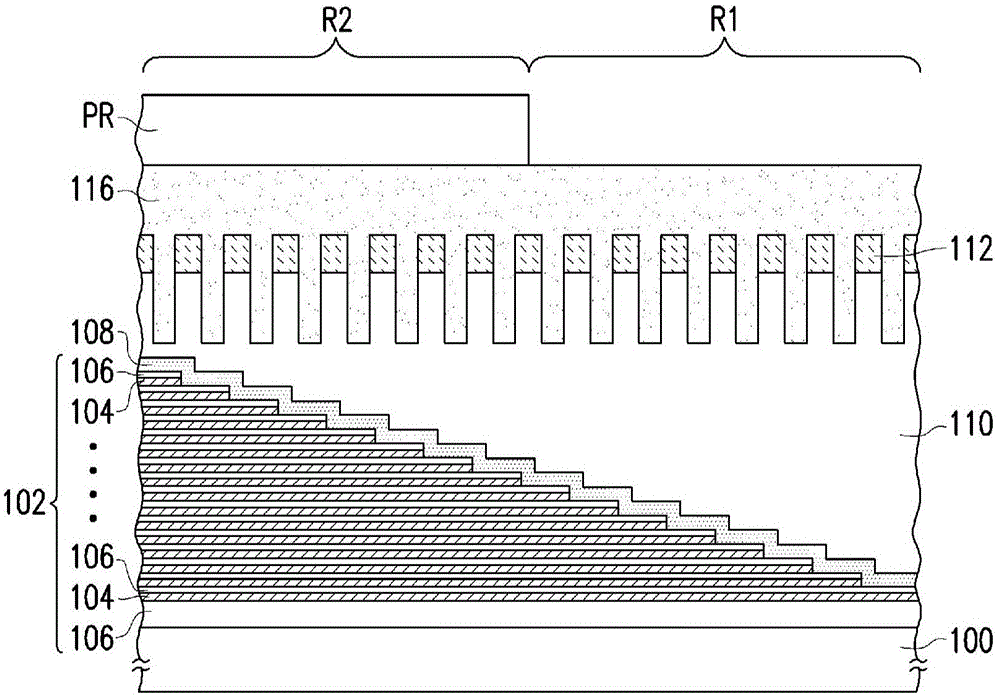

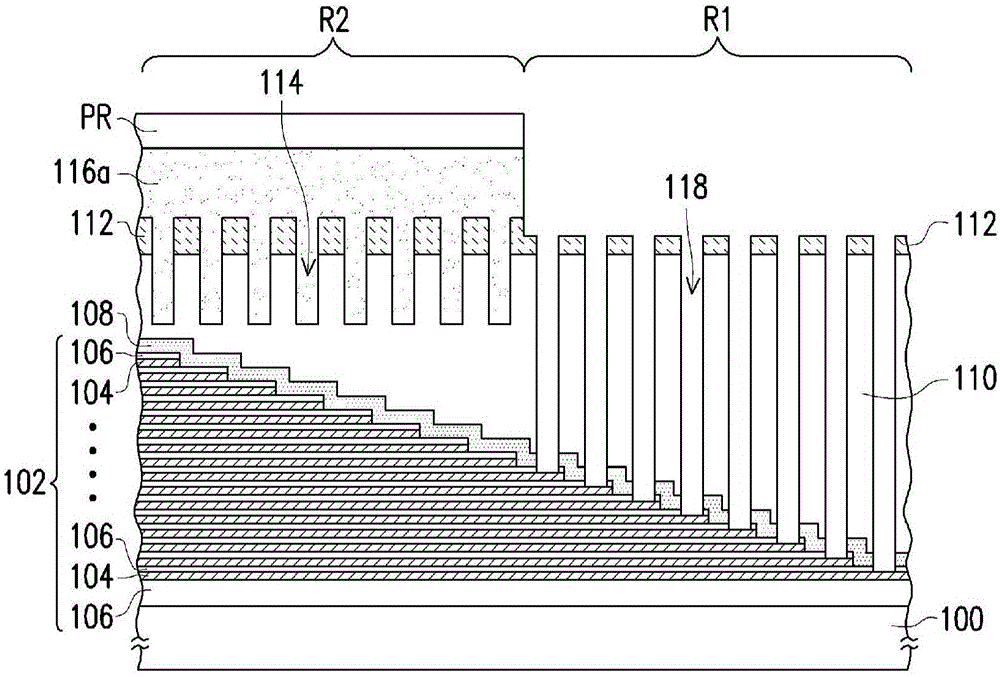

[0048] Figure 1A to Figure 1H It is a cross-sectional view of the manufacturing process of the interconnection structure according to an embodiment of the present invention.

[0049] First, please refer to Figure 1A , forming a multilayer structure 102 on the substrate 100 . The multi-layer structure 102 includes multiple layers of conductive layers 104 and multiple layers of dielectric layers 106 stacked alternately. The height of the conductor layer 104 located in the first region R1 is lower than that of the conductor layer 104 located in the second region R2. In this embodiment, the multilayer structure 102 is described by taking a ladder structure as an example, but the present invention is not limited thereto, as long as the multilayer structure 102 can be partitioned according to the height of the conductor layer 104, it belongs to the scope of the present invention. scope of protection. In addition, although this embodiment is described by taking a first region R1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com