A kind of white light led packaging device and preparation method thereof

A technology of LED packaging and LED chips, applied in semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of poor anti-sulfurization effect, difficult dispensing process, low preparation cost, etc. The effect of improving the anti-vulcanization effect and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

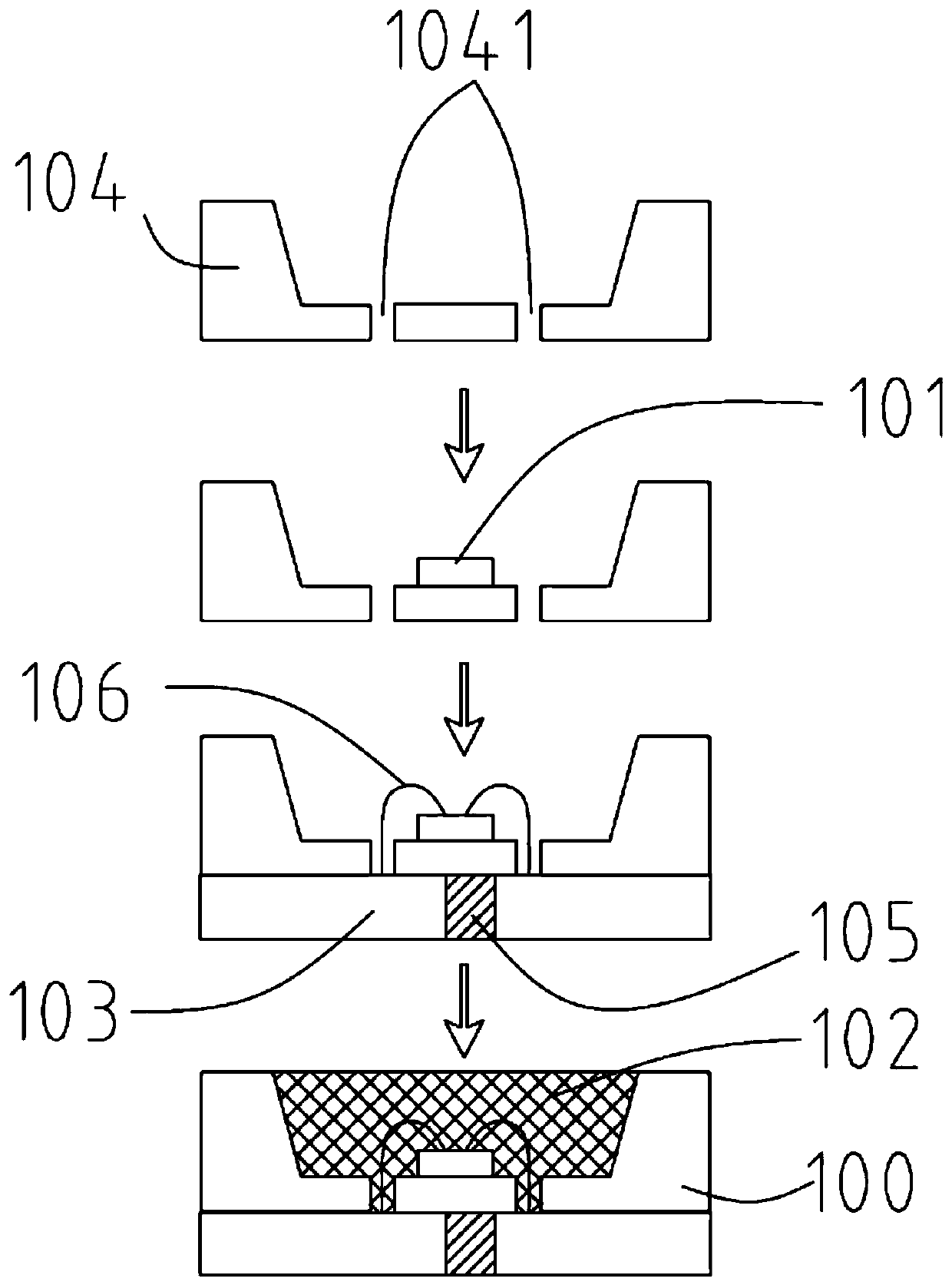

Embodiment 1

[0043] Such as figure 1 As shown, this embodiment discloses a white LED packaging device 100, including a blue LED chip 101, a light conversion layer 102, a copper sheet 103, and a thermally cured laminated on the copper sheet 103 in the initial B-stage state. The reflection sheet 104, that is, the copper sheet 103 and the bottom of the reflection sheet 104 are laminated together by thermal curing. Reflective sheet 104 is made of white reflective material, wherein, white reflective material is mainly made of silicone resin or epoxy resin as base material, and adds TiO 2 (as reflective material), SiO 2 (as a reinforcing material), so that the reflection sheet 104 has effects such as bonding and reflection, and the reflectivity of its white light area can be controlled up to more than 95%; the reflection sheet 104 is bowl-shaped, and the blue LED chip 101 is fixed on the reflection The cup bottom of the sheet 104; the light conversion layer 102 is coated on the blue LED chip 1...

Embodiment 2

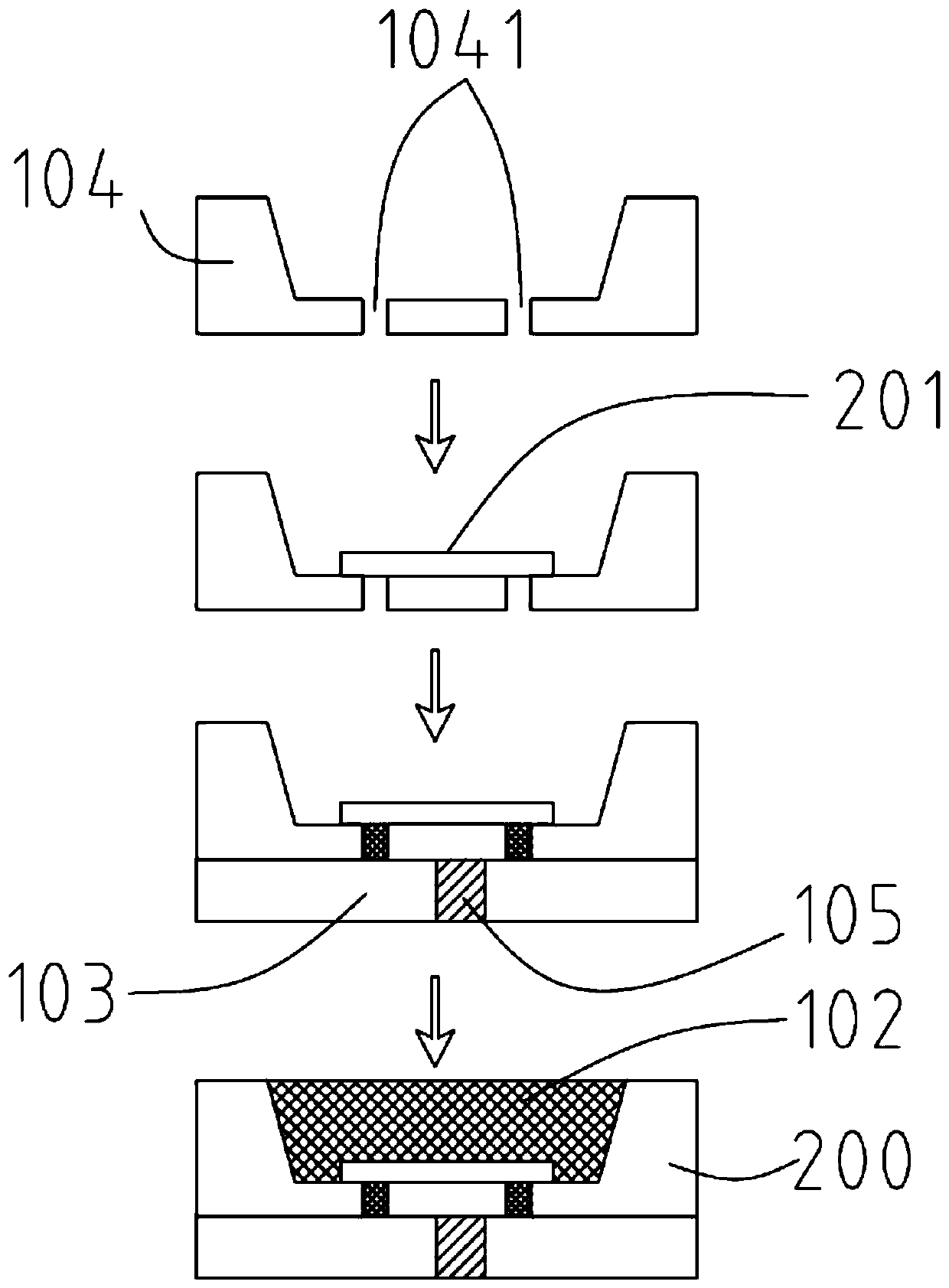

[0056] This embodiment discloses another white light LED packaging device 200, such as figure 2 As shown, structurally, it differs from the white light LED packaging device 100 described in Embodiment 1 in that:

[0057] In this embodiment, the blue LED chip 201 is selected as a flip-chip LED chip, and the pads of the blue LED chip 201 are aligned with the two through holes 1041 to directly connect with the positive and negative regions of the copper sheet 103 respectively.

[0058] This embodiment also discloses a preparation method of the white light LED packaging device 200, the simplified process of the preparation method is as follows: figure 2 As shown, the difference between it and the preparation method of the white LED packaging device 100 described in Embodiment 1 is:

[0059] In the step S1, the blue LED chip 201 is selected as a flip-chip LED chip; in the step S2, the pads of the blue LED chip 201 are aligned with the two through holes 1041, and are directly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com