Alpha-glucosidase activity inhibitory component in Yeyanghe and its preparation method and application

A technology for glucosidase activity inhibition, which is applied in the field of α-glucosidase activity inhibition components and its preparation, can solve the problems of insufficient development and utilization, and achieve the effect of less impurities, easy realization and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

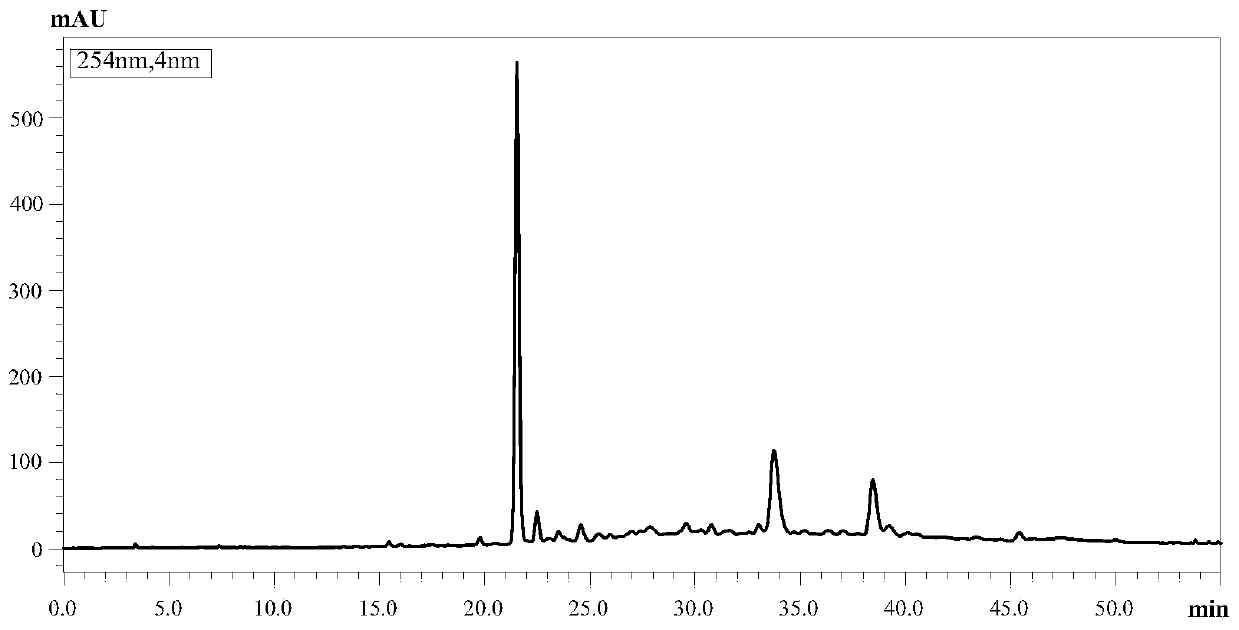

Image

Examples

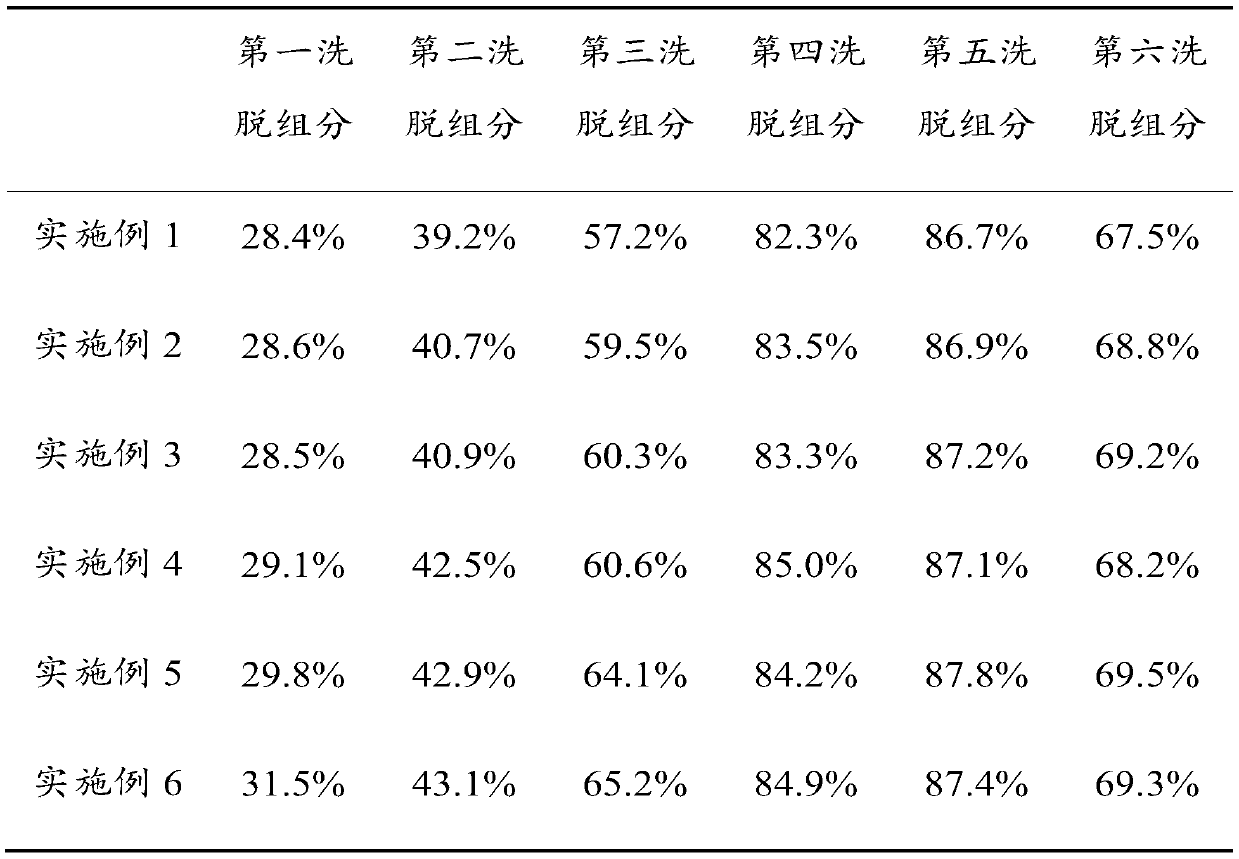

Embodiment 1

[0033] The fresh wild yanghe is crushed to a particle size of 420 μm, and the methanol-water solution is used as the extractant, wherein the volume percentage of methanol in the methanol-water solution is 90%. According to the first solid-liquid ratio of 20g:500mL, the extractant is mixed with the pulverized Yeyanghe to obtain the extract. Under the condition of 20°C and normal pressure, the extract was stirred and extracted with a magnetic stirrer for 50 hours to obtain the crude extract of Yeyanghe. The crude extract was centrifugally filtered, the supernatant was collected and separated, and the residue was repeatedly extracted twice according to the above-mentioned extraction method, and the supernatants obtained three times were combined, and the supernatant was placed in a water bath at 45°C, Rotary evaporation at a rotation speed of 50 rpm and a vacuum of 0.07 MPa to obtain a crude extract extract, the weight of which is 10% of that of Yeyanghe raw material. The wet me...

Embodiment 2

[0035] Remove impurities and wash fresh wild yanghe, dry it at 20°C, and crush it to a particle size of 580 μm. Use absolute ethanol-water solution as the extractant, wherein the volume percentage of absolute ethanol in absolute ethanol-water solution is 70 %. According to the first material-to-liquid ratio of 100g: 6000mL, the extractant is mixed with the pulverized Yeyanghe to obtain the extract. Under the condition of 30°C and normal pressure, the extract was stirred and extracted with a magnetic stirrer for 20 hours to obtain the crude extract of Yeyanghe. The crude extract was subjected to centrifugal filtration, the supernatant was collected and separated, and the residue was repeatedly extracted twice according to the above-mentioned extraction method, and the supernatants obtained respectively for three times were combined, and the supernatant was placed in a water bath at 55°C for 30 Rotary evaporation at a rotation speed of 1 / min and a vacuum of 0.08 MPa to obtain a...

Embodiment 3

[0037] Remove impurities and wash fresh wild yanghe, dry it at 45°C, and crush it to a particle size of 500 μm. Use absolute ethanol-water solution as the extractant, wherein the volume percentage of absolute ethanol in absolute ethanol-water solution is 95 %. According to the first material-to-liquid ratio of 60g: 3200mL, the extractant is mixed with the pulverized Yeyanghe to obtain the extract. Under the condition of 25°C and normal pressure, the extract was stirred and extracted with a magnetic stirrer for 35 hours to obtain the crude extract of Yeyanghe. The crude extract was subjected to centrifugal filtration, the supernatant was collected and separated, and the residue was repeatedly extracted twice according to the above-mentioned extraction method, and the supernatants obtained three times were combined, and the supernatant was placed in a water bath at 50°C, 40 Rotary evaporation at a rotation speed of 1 / min and a vacuum of 0.09 MPa to obtain a crude extract extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com