Biofilter packing composition

A biological filter, plant technology, applied in the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., can solve the problem of difficult control of the deodorization process, and achieve the effect of excellent treatment effect, reasonable collocation, and scientific and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

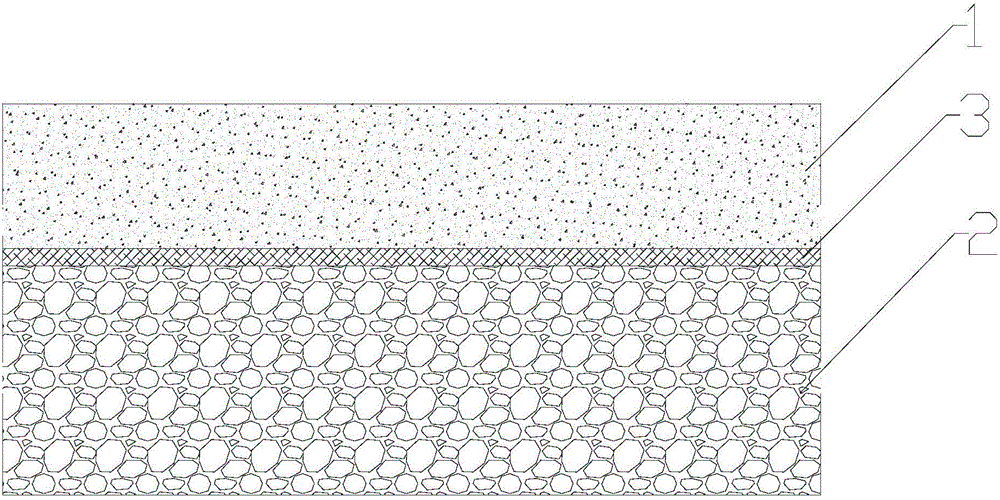

[0024] Embodiment 1: The present invention discloses a biological filter packing combination (see attached figure 1 ), the upper layer of filler includes 1 part of activated carbon, 1 part of peat, and 1 part of sawdust; the lower layer of filler includes 5 parts of coconut block, 10 parts of bark, 1 part of shell, 1 part of zeolite, and 1 part of volcanic rock. ; The upper packing 1 and the lower packing 2 are separated by a non-woven fabric. The thickness of the upper layer of filler is 1 meter, and the thickness of the lower layer of filler is 5 meters.

Embodiment 2

[0025] Embodiment 2: A kind of biofilter filler combination, the upper layer of filler includes 5 parts of activated carbon, 5 parts of peat, and 5 parts of sawdust; the lower layer of filler includes 10 parts of coconut block, 10 parts of bark, 10 parts of shell, and 10 parts of zeolite , 10 parts of volcanic rock. The upper packing 1 and the lower packing 2 are separated by a non-woven fabric. The thickness of the upper layer of filler is 3 meters, and the thickness of the lower layer of filler is 15 meters.

Embodiment 3

[0026] Example 3: A combination of biofilter fillers, the upper layer of fillers includes 1 part of activated carbon, 3 parts of peat, and 2.5 parts of wood chips; the lower layer of fillers includes 5 parts of coconut blocks, 5 parts of bark, 3 parts of shells, and 3 parts of zeolite , 3 parts of volcanic rock. The upper packing 1 and the lower packing 2 are separated by a non-woven fabric. The thickness of the upper layer of filler is 2 meters, and the thickness of the lower layer of filler is 7.5 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com