A small electromagnetic riveting gun cooling device and its realization method

An electromagnetic riveting gun and cooling device technology, applied in the field of mechanical processing, can solve the problems of damage to the coil, reduce the surface temperature of the coil, and increase the heat generation of the coil, and achieve a reduction in the contact area, dynamic friction, and compact riveting gun. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

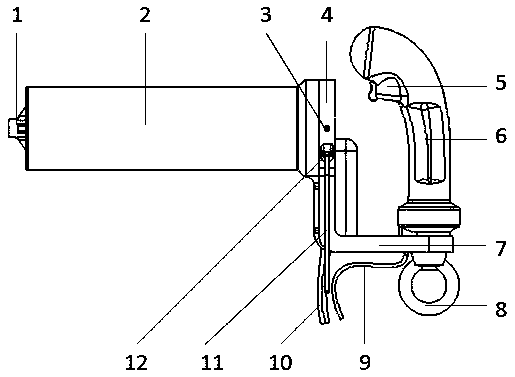

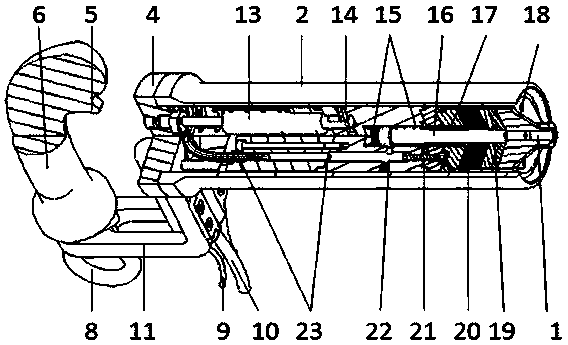

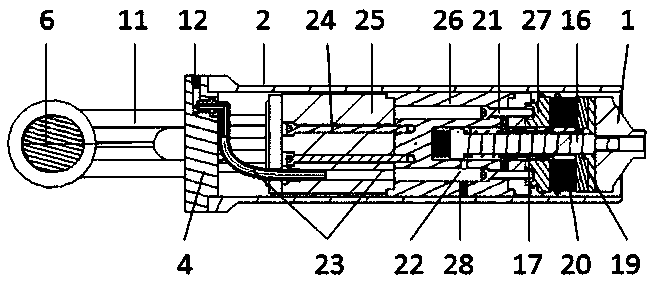

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] This embodiment provides a cooling device for a small electromagnetic riveting gun, such as Figure 1 to Figure 6As shown, it includes a trigger signal line 9 for controlling the discharge of the working coil 20 of the riveter, a power line 10 for supplying power to the working coil 20, and a conduit 11 for providing cooling gas to the working coil 20. The trigger signal line 9 is from the riveter. The lower end of the handle 6 enters the interior of the riveting gun handle 6 and is then connected to the trigger switch 5. The power cord 10 and the conduit 11 are respectively connected to the interior of the riveting gun through different entrances of the rear cover 4 of the riveting gun, and the power cord 10 is finally connected to the riveting gun. On the working coil lead wire 30, riveting energy is provided for the working coil 20. The coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com