Novel oil sunflower presser

A press, oil sunflower technology, applied in the direction of press, oil/fat production, fat production, etc., can solve the problem that the moisture of the material cannot be taken out, and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

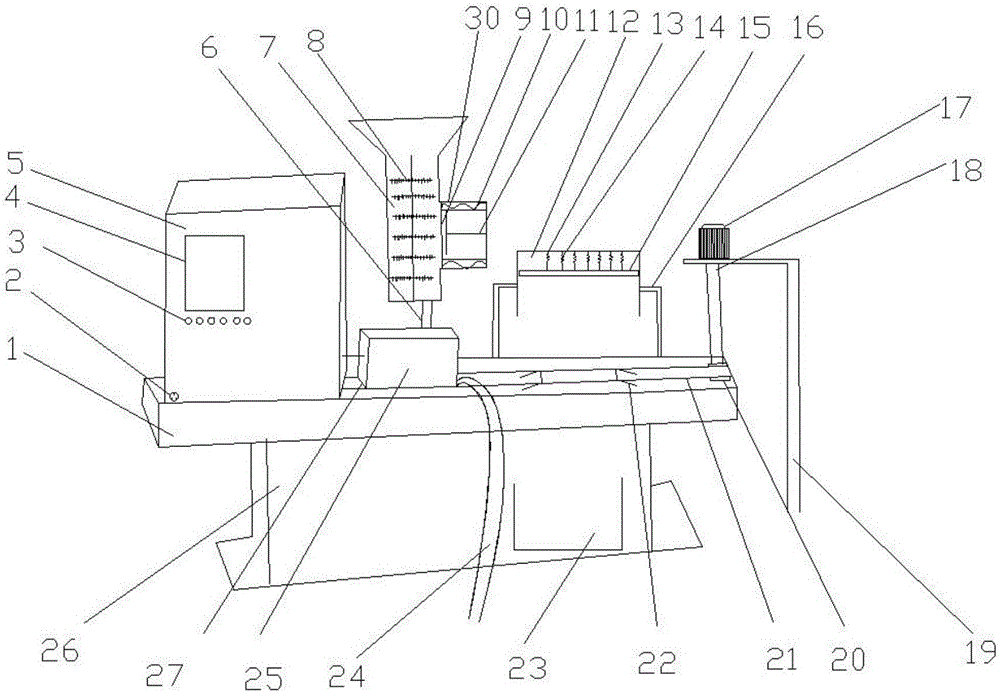

[0017] Such as Figure 1-2 As shown, a new type of oil sunflower press includes a workbench 1, an engine 17, a rolling cabinet 12, and a conveyor belt 21. The workbench 1 is above a fixed base 26, and the upper left end of the workbench 1 is provided with a control cabinet 5. A conveyor belt 21 is provided on the right side of the control cabinet 5, and a sunflower storage box 25 is slidably connected to the conveyor belt 21. A sunflower inlet hopper 7 is provided above the sunflower storage box 25, and a cutting blade is fixed inside the sunflower inlet hopper 7 8. The right side of the inlet funnel 7 is fixedly provided with an outlet case 30, the outlet case 30 is fixedly provided with a fan 11, both sides of the outlet case 30 are fixedly provided with heating wires 10, the outlet The air box 30 and the inlet funnel 7 are separated by a porous diaphragm 9. The air outlet box 30 is supported on a support column 6, the support column 6 is fixed on the ground, and the rolling ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap