Metal quality and texture specialty paper printing process

A metal texture and special paper technology, applied in printing, printing devices, etc., can solve the problems of heavy metals and fluorescent substances exceeding the standard, and achieve the effects of good environmental protection, improved production capacity and printing quality, and increased printing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

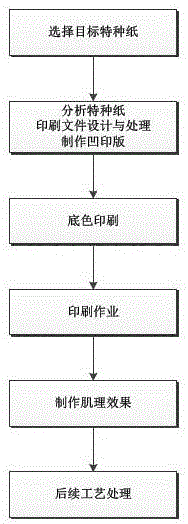

[0026] A special paper printing process with metal texture and texture, comprising the following steps:

[0027] A. Select the target specialty paper, which has metallic texture and texture;

[0028] B. Analyze the special paper, use illustrator and Photoshop software commonly used in printing to design and process printing documents, and make gravure printing plates;

[0029] C. Use pearlescent ink for background printing on white cardboard;

[0030] D. Printing with the gravure plate;

[0031] E. Use the gravure plate to squeeze the printed matter in the last printing color group, so that the printed matter has the texture effect of the special paper;

[0032] F. Subsequent processing, according to the needs of the product, carry out conventional follow-up processes such as bronzing and embossing.

[0033] The printing equipment used in the step C and the step D is a six-color printing equipment.

[0034] Three kinds of concave templates need to be produced, one of which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com