Mercaptobenzothiazoles anti-corrosion ionic liquid as well as preparation method and application thereof

A technology of mercaptobenzothiazole and ionic liquid, which is applied in the petroleum industry, additives, organic chemistry, etc., and can solve the problems of metal friction pair corrosion, degradation and easy generation of corrosive acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

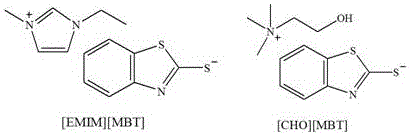

[0028] Dissolve 33.45g of mercaptobenzothiazole and 11.22g of potassium hydroxide in 50mL of methanol respectively, then mix the two in a 500mL three-necked round-bottomed flask equipped with a condenser tube and a thermometer, and stir for 30min at 40°C. The solution remains clear and transparent throughout. After the solution was cooled to room temperature, 38.21 g of 1-methyl-3-ethylimidazole chloride was added, and the reaction was stirred for 36 hours, during which a precipitate gradually formed. The product was filtered through slow filter paper, washed three times with 150mL methanol, the filtrate was rotary evaporated to remove the solvent, and then vacuum-dried at 80°C for 24h to obtain a mercaptobenzothiazole corrosion-resistant ionic liquid, which was designated as [EMIM][MBT].

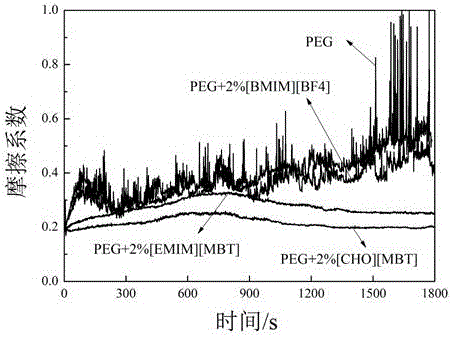

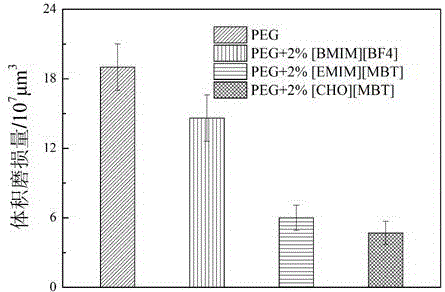

[0029] Dissolve 1g of mercaptobenzothiazole-based anti-corrosion ionic liquid [EMIM][MBT] in 99g of base oil PEG200, and disperse by ultrasonic wave for 3min to obtain 100g of lubricant com...

Embodiment 2

[0031]Dissolve 33.45g of mercaptobenzothiazole and 11.22g of potassium hydroxide in 50mL of methanol respectively, then mix the two in a 500mL three-necked round-bottomed flask equipped with a condenser tube and a thermometer, and stir for 30min at 40°C. The solution remains clear and transparent throughout. After the solution was cooled to room temperature, 42.03 g of 1-methyl-3-ethylimidazole chloride was added, and the reaction was stirred for 20 h, during which a precipitate gradually formed. The product was filtered through slow filter paper, washed three times with 150mL methanol, the filtrate was rotary evaporated to remove the solvent, and then vacuum-dried at 80°C for 24h to obtain a mercaptobenzothiazole corrosion-resistant ionic liquid, which was designated as [EMIM][MBT].

[0032] Dissolve 1g of mercaptobenzothiazole anti-corrosion ionic liquid [EMIM][MBT] in 99g of base oil PEG400, and disperse by ultrasonic wave for 3min to obtain 100g of lubricant combination co...

Embodiment 3

[0034] Dissolve 33.45g of mercaptobenzothiazole and 11.22g of potassium hydroxide in 50mL of methanol respectively, then mix the two in a 500mL three-necked round-bottomed flask equipped with a condenser tube and a thermometer, and stir for 30min at 40°C. The solution remains clear and transparent throughout. After the solution was cooled to room temperature, 38.21 g of 1-methyl-3-ethylimidazole chloride was added, and the reaction was stirred for 36 hours, during which a precipitate gradually formed. The product was filtered through slow filter paper, washed three times with 150mL methanol, the filtrate was rotary evaporated to remove the solvent, and then vacuum-dried at 80°C for 24h to obtain a mercaptobenzothiazole corrosion-resistant ionic liquid, which was designated as [EMIM][MBT].

[0035] Dissolve 2g of mercaptobenzothiazole-based anti-corrosion ionic liquid [EMIM][MBT] in 98g of base oil PEG600, and disperse by ultrasonic wave for 3 minutes to obtain 100g of lubrican...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com