Insertion strip machining method

A processing method and fillet technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as metal copper waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The molding method comprises the steps of:

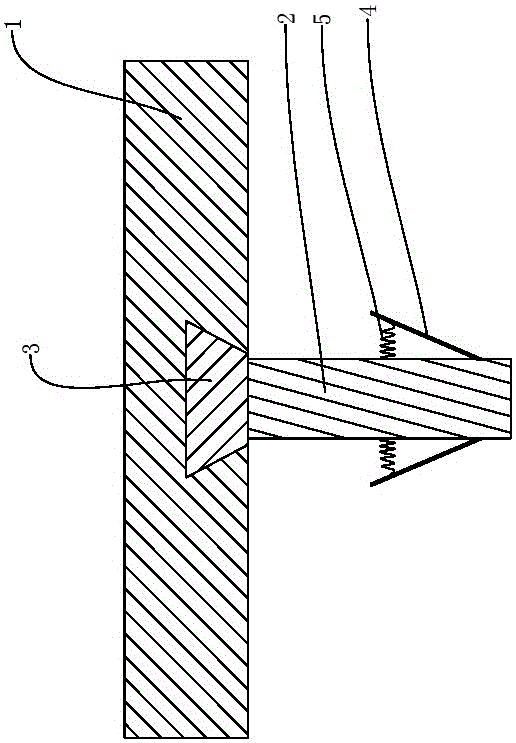

[0032] Panel manufacturing steps: choose a wooden strip with a width of 2cm as the panel of the fillet, the upper surface of the panel is the contact surface, and a dovetail groove is cut on the lower surface of the panel;

[0033] Carbonization of the surface of the panel: Sprinkle the sawdust on the contact surface of the panel, then burn the contact surface with an oxygen torch for 3-5 seconds, after the sawdust is burnt out, sand the contact surface with sandpaper, and residue removal;

[0034] Manufacturing steps of the connecting plate: select a piece of wood as the connecting plate, one side of the connecting plate is provided with a clip matching the shape of the dovetail groove, and glue and fix the shrapnel on the connecting plate;

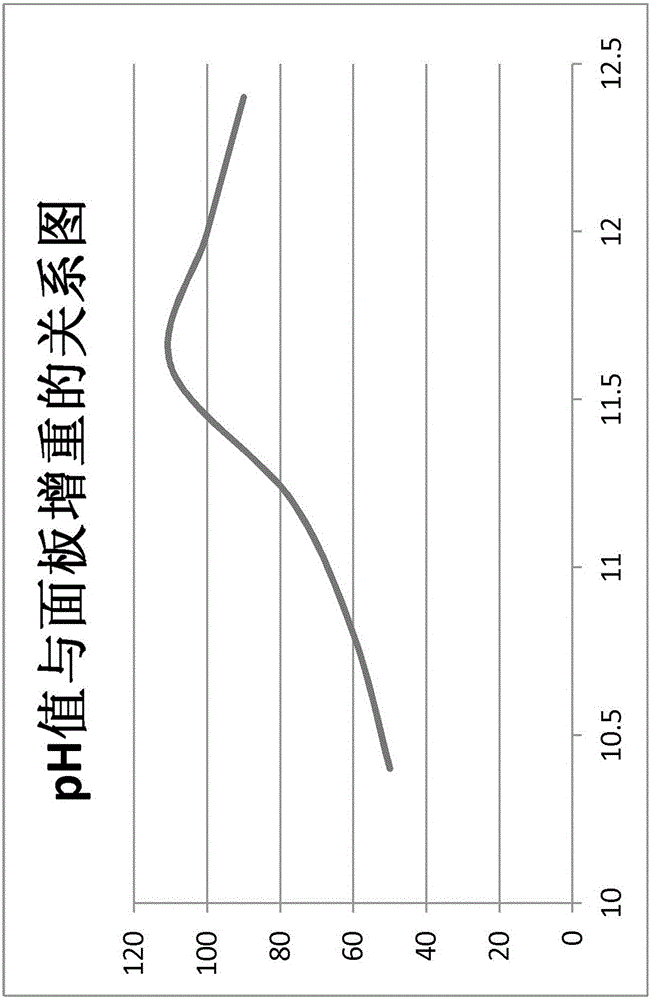

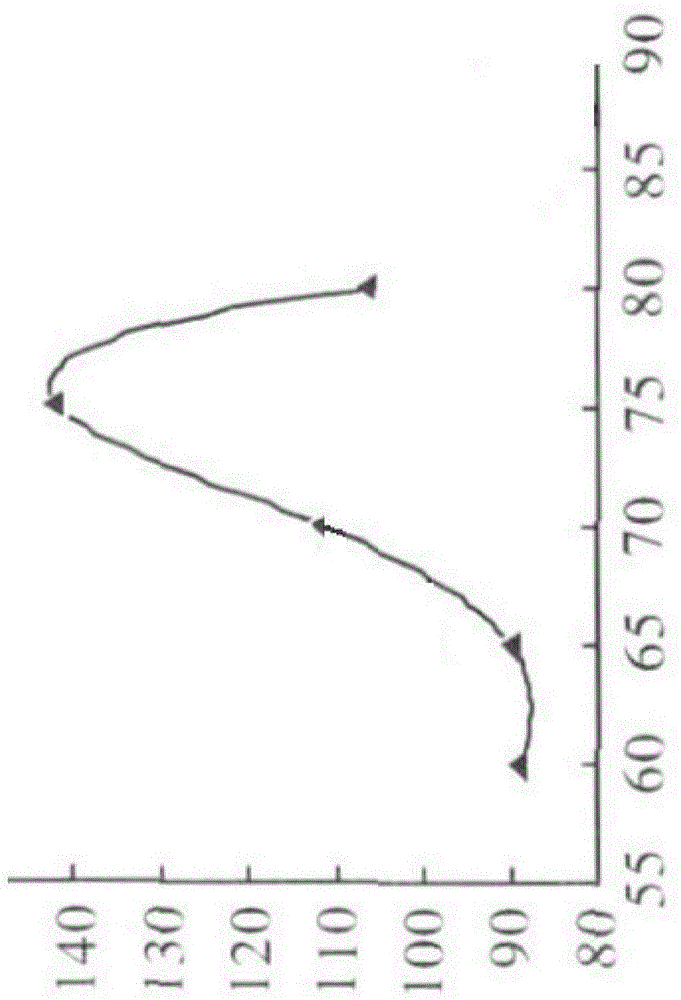

[0035] Panel surface treatment: select and configure the plating solution, which is packed in a long container, add 500ml of water, and then configure the plating solution, add 9.663g ...

Embodiment 2

[0047] Compared with Embodiment 1, the difference lies in that the clip and the connecting plate are integrally formed. The clip and the connection plate are integrally formed to facilitate processing, and the fewer connection points, the higher the stability.

Embodiment 3

[0049] Compared with Example 1, the difference is that in the panel making step, patterns can be carved on the contact surface of the panel, and then before the carbonization step of the panel surface, wood wax oil is applied on the panel, and after waiting for 3-5 hours , and then carry out the panel surface carbonization step, after the panel surface carbonization step, apply iron powder or zinc powder on the gaps of the pattern on the contact surface. The concentration of the plating solution in the gaps of the patterns will decrease. In severe cases, the copper plating layer may fill the gaps of the patterns, which seriously affects the appearance. Iron powder or zinc powder has strong reducibility, and copper sulfate in the plating solution will be preferred. React with iron powder or zinc powder in the pattern gap. The main form of wood wax oil is palm wax. As a kind of vegetable oil, palm wax will not change its properties when the temperature is below 180°C, but when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com