A prefabricated cavity panel forming a two-way stressed floor

A prefabricated, cavity board technology, which is applied to floors, buildings, building components, etc., can solve the problems of long solidification and hardening time of hollow fillers, difficult industrial production, and inconvenient production and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below in conjunction with the accompanying drawings.

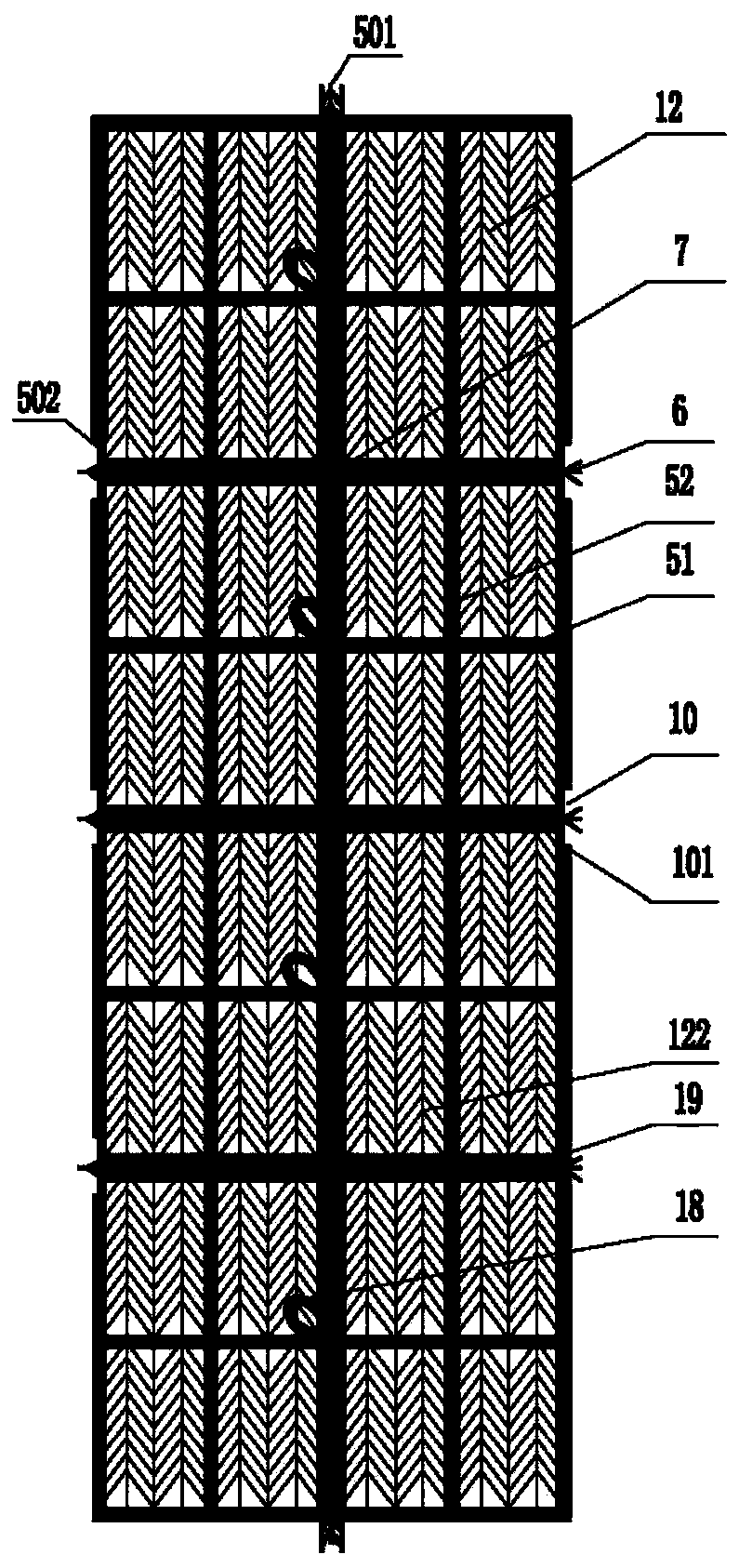

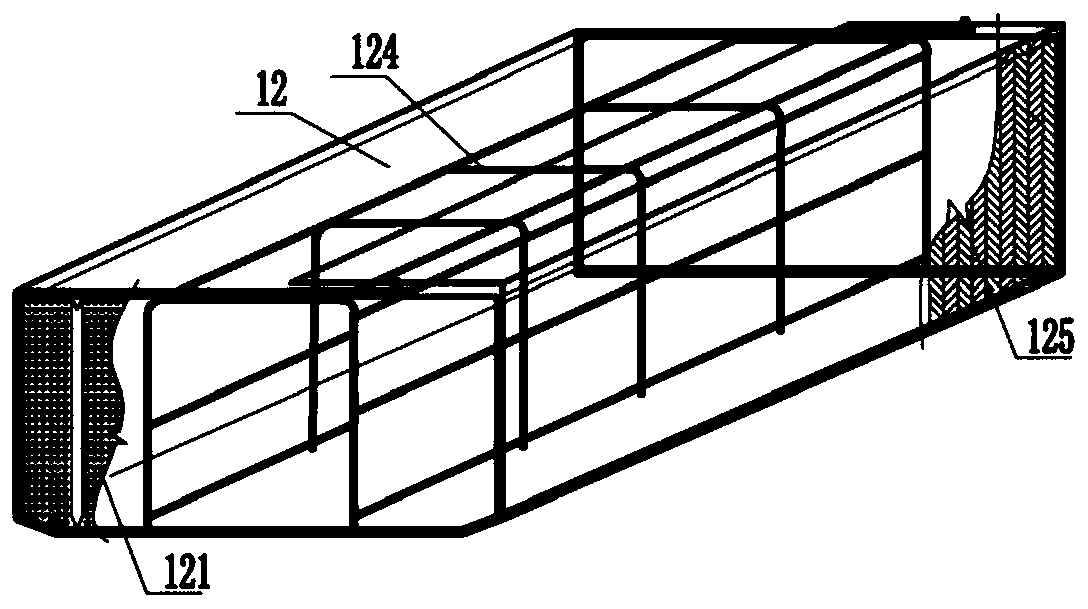

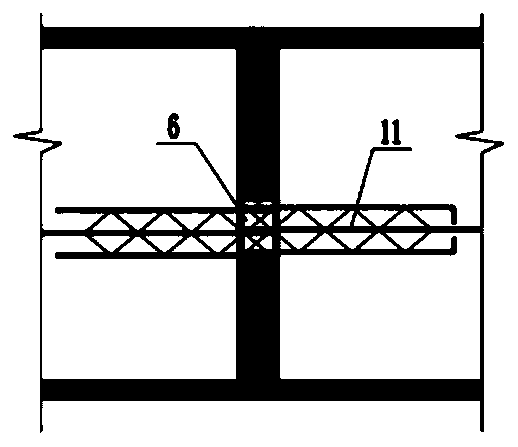

[0025] figure 1It is a plan view of a prefabricated cavity panel forming a two-way force-bearing floor of the present invention. When the present invention is implemented, a prefabricated cavity plate forming a two-way force-bearing floor is determined according to the secondary design decomposition of the architectural design drawings. The production is organized according to the number of decomposed standard parts or special-shaped parts; the prefabricated cavity panel 7 is a prefabricated concrete component, including longitudinal ribs 52 and exposed at both ends of the longitudinal ribs, and two adjacent cavity panels with two-way force are to be formed. The short ribs are connected 51 to form two-way stressed steel bars, and the device 10 is exposed at the ends of the short transverse ribs, and the end positions of the short transverse ribs are temporarily wrapped by frag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com