Dynamic weighing system for use in industrial de-dusting filter cloth weaving technology

A technology of dynamic weighing system and filter cloth, which is applied in the field of mechanical equipment, can solve problems such as large errors and achieve remarkable technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

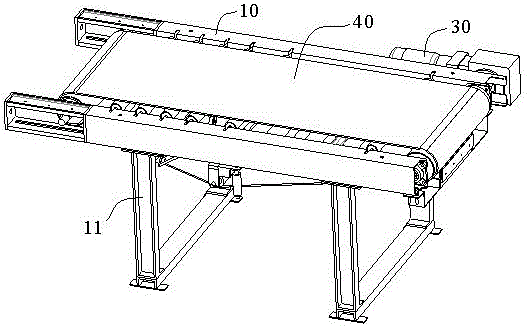

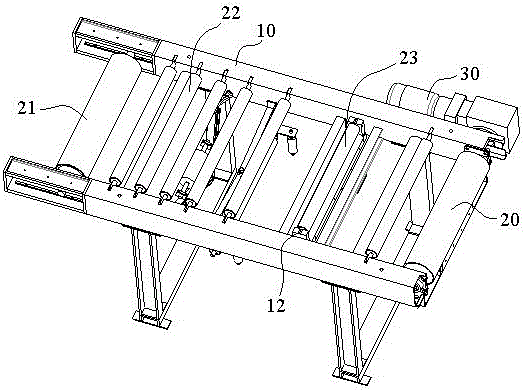

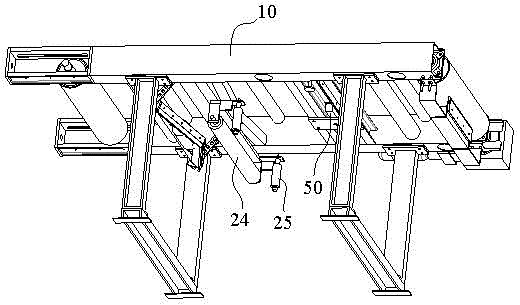

[0012] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a dynamic weighing system for the weaving process of industrial dust removal filter cloth, comprising a frame body 10, on which a rotating roller group unit is laid, and the rotating roller group unit includes driving rollers 20, Driven drum 21, idler roller 22 and floating roller 23; said rotating roller group unit is provided with belt 40; The bottom of said belt 40 upper layer is provided with weighing unit, and said weighing unit includes restraining floating roller 23 to move up and down The guide plate 12, the bottom of the floating roller 23 is provided with a pressure sensor 50, wherein the floating roller 23 can roll and support the belt 40 on the one hand, and can evenly apply the gravity of the moving belt 40 to the pressure sensor 50 on the other hand , compared with the sensor in the prior art that directly measures the pressure of the belt 40 under load, the stress uniformit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com