Engine cylinder's inner near-wall flow field testing device

An engine cylinder and testing device technology, which is applied in the direction of measuring device, machine/structural component testing, internal combustion engine testing, etc., can solve the problems of difficult to obtain the flow field in the blind zone in the cylinder and the small area of the piston top window, and achieves compact structure and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principle and structure of the device of the present invention will be further described below in conjunction with the accompanying drawings and examples.

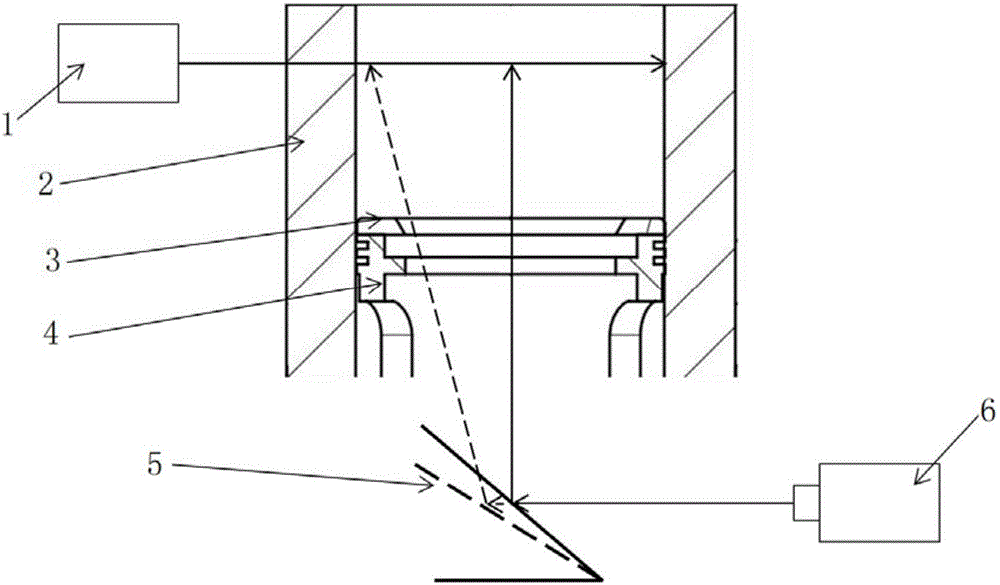

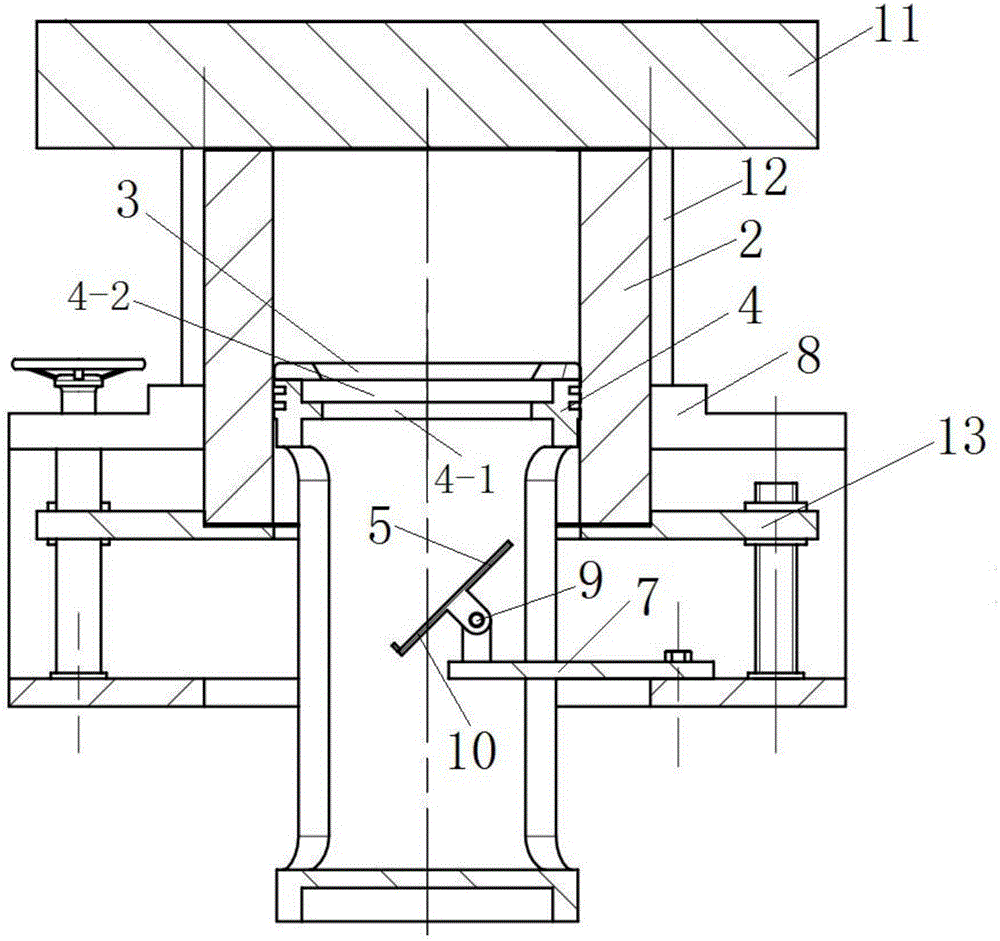

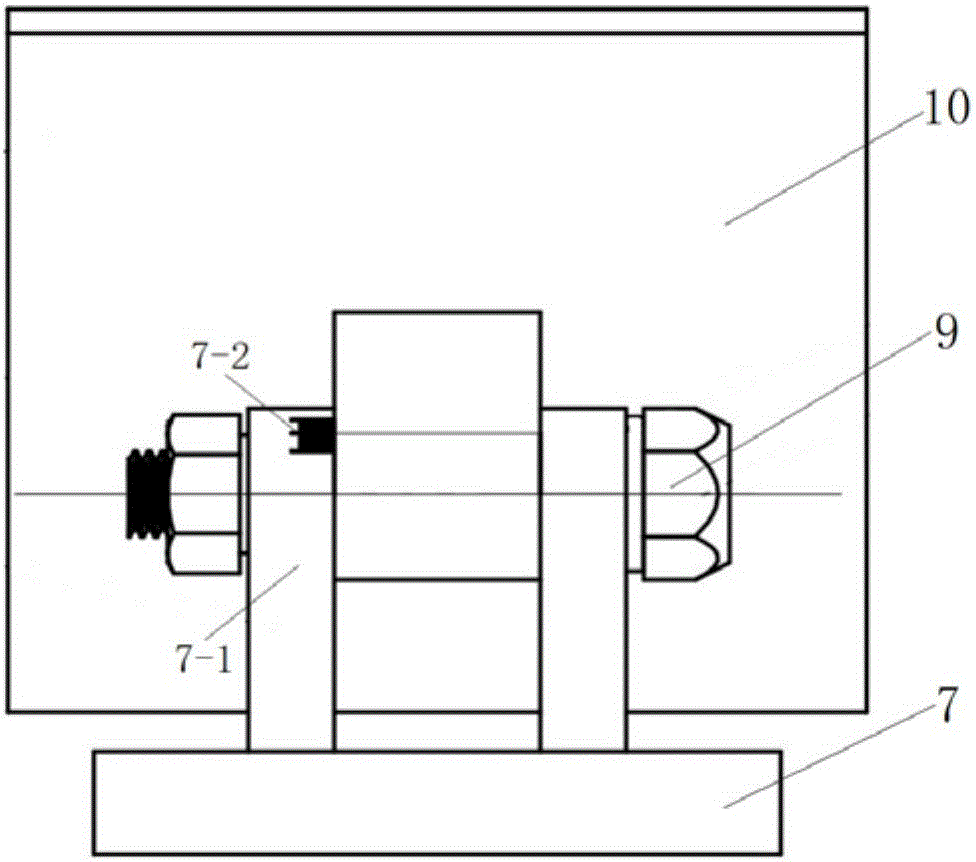

[0012] The test device for the flow field near the wall in the engine cylinder is composed of: the quartz glass cylinder liner 2 is sequentially assembled with the piston top cover plate 3, the extended piston 4, and the reflector 5, and the quartz glass cylinder liner is equipped with a laser device 1 respectively. With optical camera 6, reflector support 7 is installed on the surface of bottom plate of extension body 8 and stretches in the extension piston. The bolt 9 passes through the screw hole on the back of the swivel frame 10 and is connected with the reflector support shaft, the reflector is mounted on the swivel frame, and the angle of the reflector can be adjusted freely within the range of -45° to +45°. The top of the extended piston has a window hole 4-1 and is provided with a stop 4-2, and quartz g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com