Dust cutter calibration system and calibration method therefor

A technology for calibrating systems and cutters, applied in the field of calibration systems, to achieve the effects of intuitive and accurate detection results, uniform dust environment, and accurate response to capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

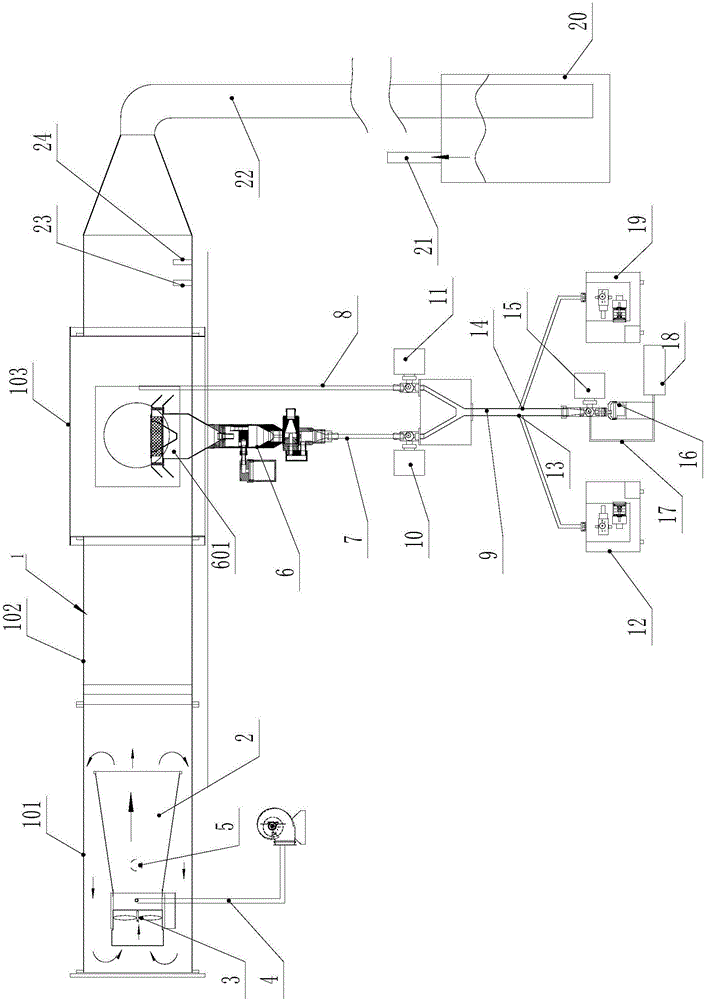

[0038] Such as figure 1 As shown, a calibration system for a dust cutter 6 includes dust environment simulation equipment and a calibration pipeline system connected with the dust environment simulation equipment. The dust environment simulation equipment includes a wind tunnel 1, and the wind tunnel 1 is sequentially connected to The mixing section 101, the transition section 102 and the test section 103, the upstream end of the mixing section 101 is provided with a sealing end plate, and the sealing end plate blocks the upstream of the mixing section 101 to facilitate the formation of backflow in the sub-mixing section 101, The mixing section 101 is provided with an active diffusion cylinder 2, the active diffusion cylinder 2 is trumpet-shaped, and the large-diameter end of the active diffusion section is the downstream end to facilitate the diffusion of dust particles. The upstream end of the active diffusion cylinder 2 is Positive pressure blower 3 is provided; The downstr...

Embodiment 2

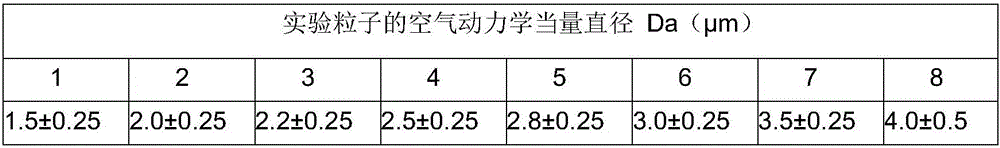

[0047] A calibration method for a dust cutter 6, the calibration method comprising:

[0048] A. Provide a wind tunnel 1 to simulate the dust environment, and the dust of the specified particle size is added to the wind tunnel 1 to obtain uniformly distributed dusty gas; the structure of the wind tunnel 1 can adopt the structure of the wind tunnel 1 in embodiment 1, or can Dust environment is simulated by other wind tunnel 1.

[0049] B, provide a dust cutter 6, the sampling head of this dust cutter 6 is positioned in the uniform dust environment in wind tunnel 1;

[0050] C. The dust-containing gas is pumped into the dust cutter 6 for dust separation, and the separated dust-containing gas is sampled by a calibrated particle size spectrometer to obtain the dust concentration C of the separated dust-containing gas 1 ;

[0051] D. Sampling the dust environment around the dust cutter 6 sampling head in the wind tunnel 1 to obtain unseparated dust-containing gas, and sampling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com