Detection method of change rule of plastisol moulding degree of nitro-cotton in high-solid-content propellant

A technology with high solid content and regularity of change, applied in the direction of analysis using nuclear magnetic resonance, etc., can solve the problems of the development stage and the increase of the impact force of the particles, and achieve the effect of good physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The new energetic plasticizer azidonitroamine DIANP is liquid at room temperature, not only has the advantages of high energy, high burning rate, low burning temperature, small relative molecular weight of gas, large gas production, etc., but also has good impact sensitivity, friction sensitivity and heat sensitivity. It is smaller than the commonly used energetic plasticizer NG.

[0056] DIANP can significantly improve the mechanical properties of propellants, especially the low-temperature mechanical properties compared with NG. DIANP is used to replace part of NG in standard propellants to make modified double-base or modified triple-base propellants, which have been mass-produced.

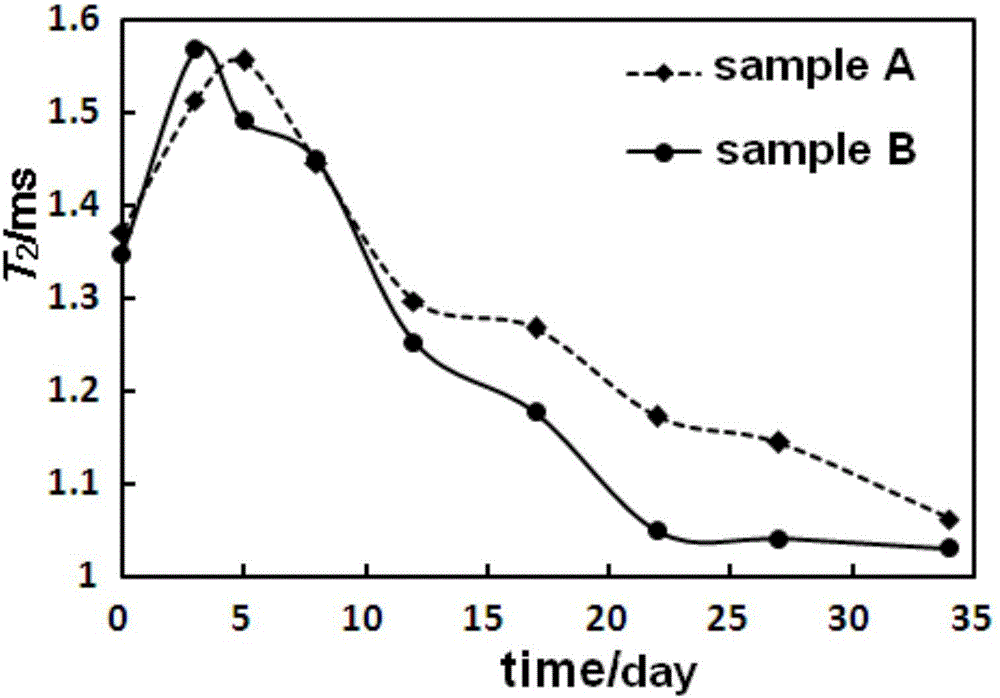

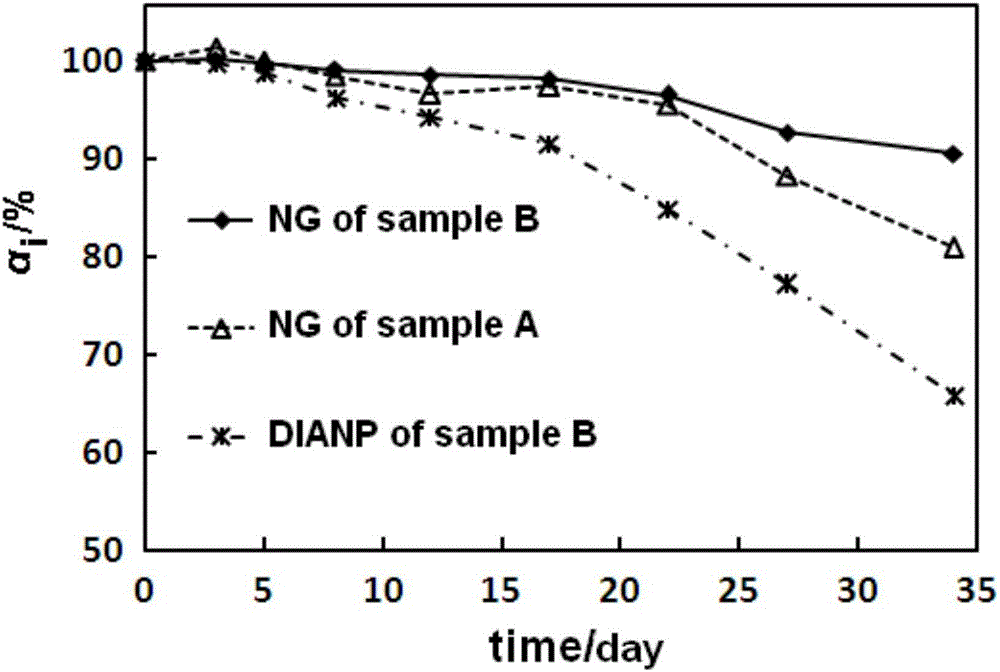

[0057] The purpose of the study in this example is to compare the plasticizing effects of DIANP and NG on NC in propellants with high solid content.

[0058] The thermal aging method is used to speed up the decomposition of NC, NG and DIANP in the propellant samples, and the samples are ...

Embodiment 2

[0087] The safe use of propellant is related to the ballistic performance of the weapon. At present, it is still impossible to establish the relationship between the thermal decomposition of the propellant in storage and the ballistic properties of the propellant. Therefore, it cannot be estimated, and its service life can only be determined through shooting tests. , extremely expensive. Although the safe service life can be judged by measuring the heat of propellant, the decrease of NC viscosity and mechanical properties in the propellant, the error is large and the factors are complicated. The mechanical properties of propellants with high solid content have a great influence on the ballistic performance. Researchers at home and abroad are looking for parameters to characterize the mechanical properties of propellants with high solid content more accurately, so as to judge the safe service life of propellants.

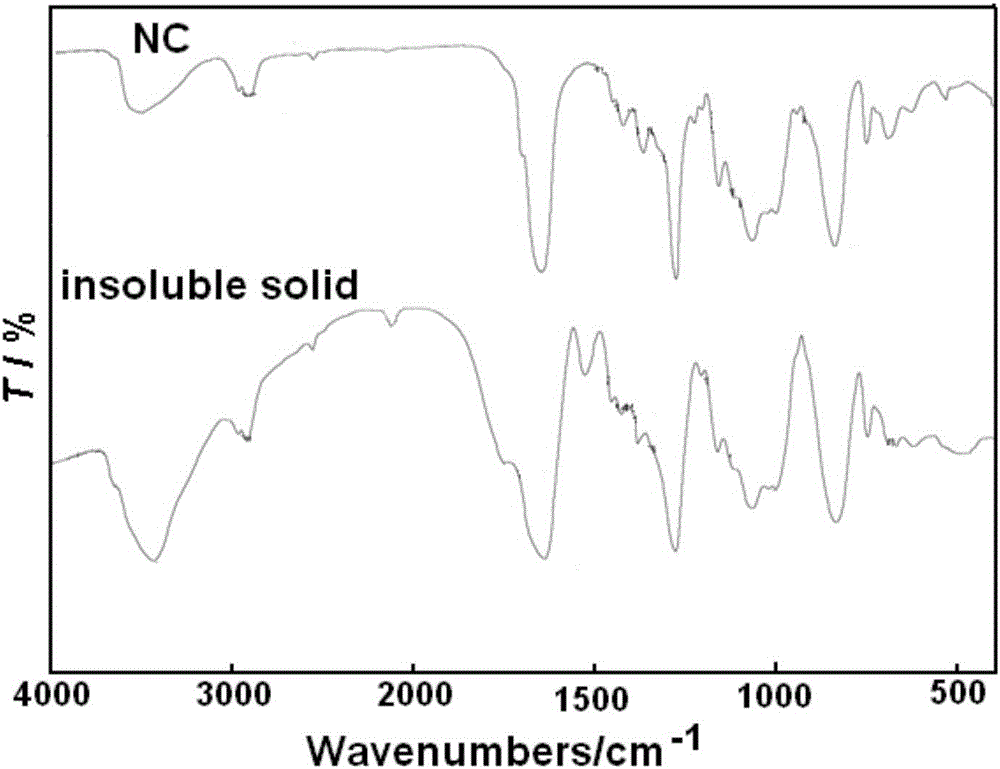

[0088] NC has a semi-rigid molecular chain. In order to improve...

Embodiment 3

[0096] The performance of propellants is not only related to the formula, but also closely related to the process. The improvement of propellant performance often brings innovation or improvement of technology and promotes the development of technology. Similarly, the development of technology meets the performance requirements of propellants, and products with uniform quality and stable performance can be manufactured economically and safely. When developing new propellant powder, it is always advocated that the manufacturing process of propellant powder should be adapted to the specific formula, and the principle of safe and economical production of high-quality propellant powder should not be limited to a certain unchanging process mode. . In fact, the improvement of specific process methods caused by different formulations often occurs. Therefore, the development of propellant technology has always been paid attention to, and it is one of the subjects of people's researc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com